6 - 24

Replacement

Maintenance &

Replacement

Maintenance &

Replacement

Sub tension assy

1. Remove the tension base from the machine.

2. Remove the cap from the thread guide tension screw.

3. Remove the thread guide tension screw from the tension

base.

*Key point

• When the thread guide tension screw is removed

from the tension base, Nut 2 M3 in the tension base

comes off. Be sure to keep it for later use.

4. If the upper thread eyelet base and thread guide tension

plate are detached, set them on the tension base again.

5. Attach the thread guide compression to the sub tension

assy.

6. Secure the nut (Nut 2 M3) into the hole of the tension base

to attach the sub tension assy to the tension base.

7. Attach the cap to the sub tension assy.

8. Turn all sub tension assy tabs anti-clockwise so that they

are at the highest position to provide the least load onto

the upper thread.

9. Sew trial stitches to check if it works properly.

*Key point

• If it does not sew properly, fine-tune the upper thread

tension by turning the tab.

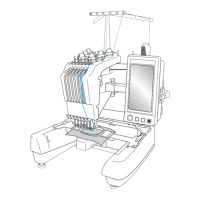

To replace the “thread guide tension screw” to the upper thread adjustable “sub tension assy” on the machine with

“thread guide tension screw”, follow the instructions below.

Tension base

Nut 2 M3

Upper thread

eyelet base

Thread guide

tension plate

Thread guide

tension screw

Cap

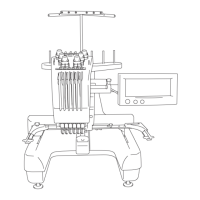

Tension base

Nut 2 M3

Upper thread

eyelet base

Thread guide

tension plate

Cap

Sub tension assy

Thread guide

compression

Loading...

Loading...