Loading...

Loading...

Do you have a question about the Brother PR655 and is the answer not in the manual?

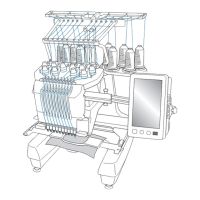

| Number of Needles | 6 |

|---|---|

| Built-in Designs | 25 |

| USB Port | Yes |

| LCD Display | Yes |

| Type | Embroidery Machine |

| Built-in Fonts | 28 |

| Maximum Speed | 1000 stitches per minute |

| Embroidery Area | 300mm x 200mm |

Covers disassembly procedures for the main components of the machine.

Covers assembly of the primary structural and external parts.

Procedures for adjusting critical machine parameters.

Process for inputting specific needle bar data for calibration.

Procedure for adjusting the tension of the main motor drive belt.

Procedure for adjusting the tension of the timing belt.

Adjustment for the needle's front-to-back position relative to the plate.

Adjustment for the needle's left-to-right position relative to the plate.

Adjustment for needle bar height and clearance with the rotary hook.

Procedure for setting the correct vertical position of the needle bar.

Adjustment for the clearance between the rotary hook stopper and the hook.

Procedure for setting the correct height of the presser foot.

Adjustment for the needle bar's highest position relative to the top dead center plate.

Adjustment for the vertical movement of the needle threader mechanism.

Adjustment for the horizontal movement of the needle threader mechanism.

Adjustment for the tension of the Y-axis belt.

Adjustment for the tension of the X-axis belt.

Adjustment for the proper activation of the picker mechanism.

Setting the initial position of the movable thread cutting knife.

Adjusting the vertical position of the thread presser base.

Calibrating the hoop sensor by adjusting its A/D values.

Setting the home or initial position for the X and Y carriages.

Adjusting the force required to engage the movable and fixed knives.

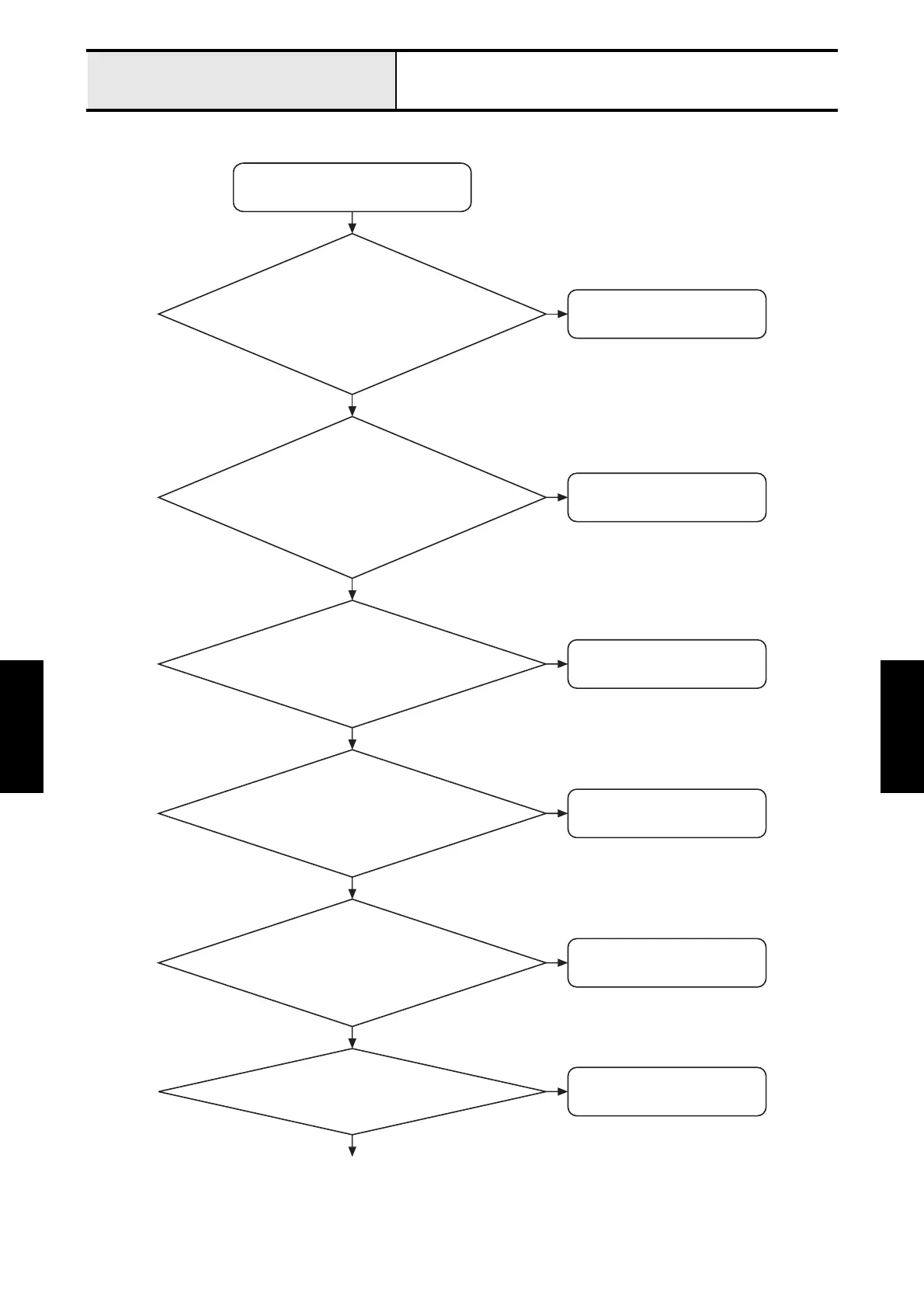

Troubleshooting steps when the machine does not power on.

Troubleshooting steps when the touch panel is unresponsive.

Troubleshooting steps when panel switches are not functioning.

Troubleshooting steps when the needle bar movement is abnormal.

Troubleshooting steps when the thread breakage sensor fails.

Troubleshooting steps when the embroidery hoop movement is abnormal.

Troubleshooting steps when the main shaft rotation is abnormal.

Troubleshooting steps when the thread cutting mechanism fails.

Procedures for replacing major machine components.