4 - 26

Inspection and

Adjustment

Inspection and

Adjustment

Adjustment Needle bar top dead center

[Standard]

When the needle bar is in highest position, there should not be clearance between the top dead center plate and the

cushion rubber. And the cushion rubber should be compressed slightly (approx. 0.3 mm).

[Adjustment]

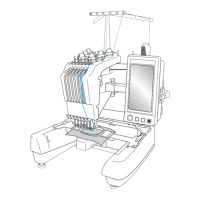

1. Start the test mode and select [#12: Needle threader] under [MAIN

BOARD TEST MODE].

2. Press the [L-R position] and the standard needle bar for adjustment

will be selected automatically. The needle bar case unit will move to

the left and right.

3. Turn the pulley by hand to move the needle bar to the top point.

4. Loosen the 2 screws 1 of the top dead center plate.

5. Push the top dead center plate towards the needle bar (downward) so

that the cushion rubber is compressed slightly, and tighten the 2

screws 1 to secure the dead center plate.

6. Check the needle threader.

*Key point

• When needing the adjustment of the needle threader, make

adjustments following the guidelines in section “4-27 Needle

threader (up/down)” and “4-29 Needle threader (left/right)”.

7. Move the needle bar to the top point again, check that the all top

dead center plates of the needle bars are the same height.

*Key point

• When differing the height of the top dead center plate, make

adjustments of steps 4 to 5 above.

1

Screw, Bind

M4X6

The height of the

top dead center

plates are same.

1

Top dead center plate

Cushion rubber

Loading...

Loading...