4 - 22

Inspection and

Adjustment

Inspection and

Adjustment

Adjustment Needle bar height

[Standard]

The gap between the top of needle eye and the outer rotary hook point in the up/down direction should be 1.8 to 2.2

mm when the right edge of the needle matches up with the outer rotary hook point.

The thread guide of the needle bar should be facing directly frontward.

[Adjustment]

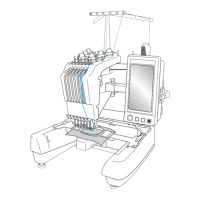

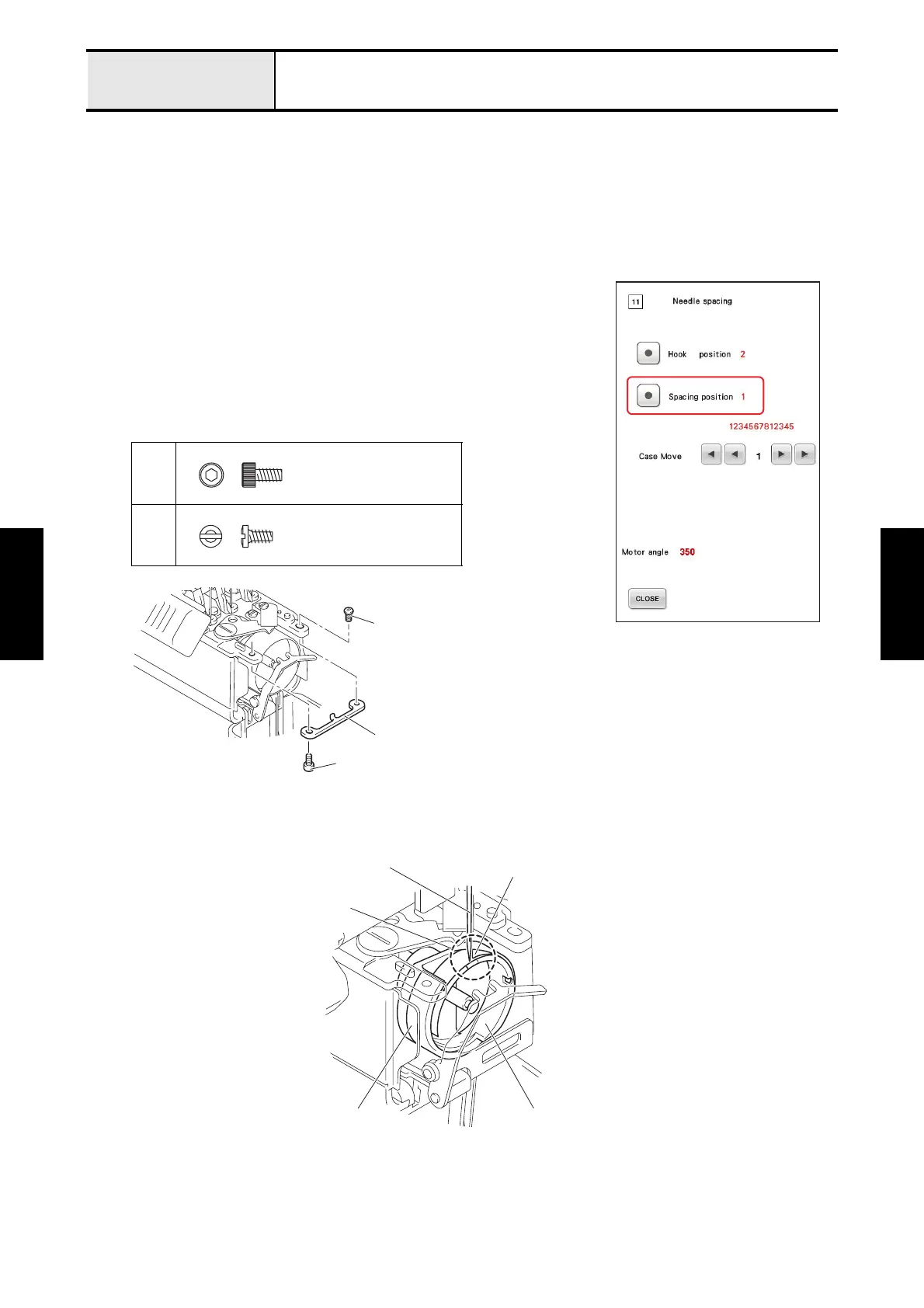

1. Start the test mode and select [#11: Needle spacing] under [MAIN

BOARD TEST MODE].

2. Press the [Spacing position] and the standard needle bar for adjustment

will be selected automatically. The needle bar case unit will move to

the left and right.

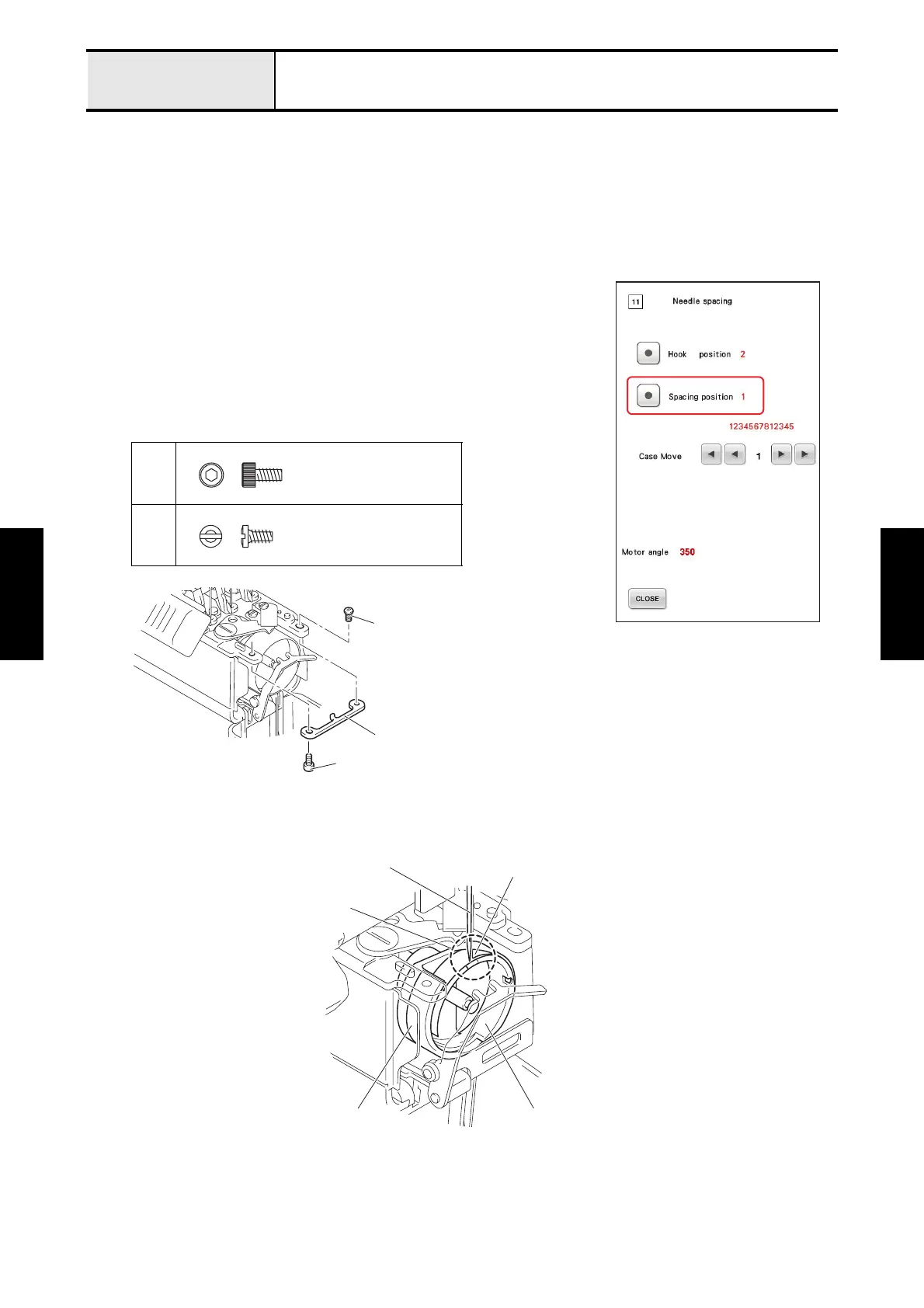

3. Remove the 2 screws of the needle plate to remove the needle plate.

4. Remove the screw 1 and screw 2 of the rotary hook stopper to

remove the rotary hook stopper.

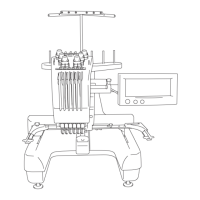

5. Turn the inner rotary by hand until it reaches a position (A) such that the right edge of the needle and the outer

rotary hook point look like they match up with each other.

To next page

1

2

Bolt, Socket

M3X6

Screw

2

1

Rotary hook stopper

with hex wrench 2.5 mm

Needle

"A"

Inner rotary

Outer rotary hook point

Outer rotary

Loading...

Loading...