1 ENGINE

82410 • 82710 • 82910

WSM,

12271

OOOOOF10100

OOOOOF10090

Correcting

Valve

and

Valve Seat

• NOTE

•

Before

correcting

the

valve

and

seat,

check

the

valve

stem

and

the

1.0.

of

the

valve

guide

section,

and

repair

them

if

necessary.

•

After

correcting

the

valve seat, be

sure

to

check

the

valve

recessing.

1)

Correcting

Valve

1.

Correct the valve with a valve refacer.

2)

Correcting

Valve Seat

1.

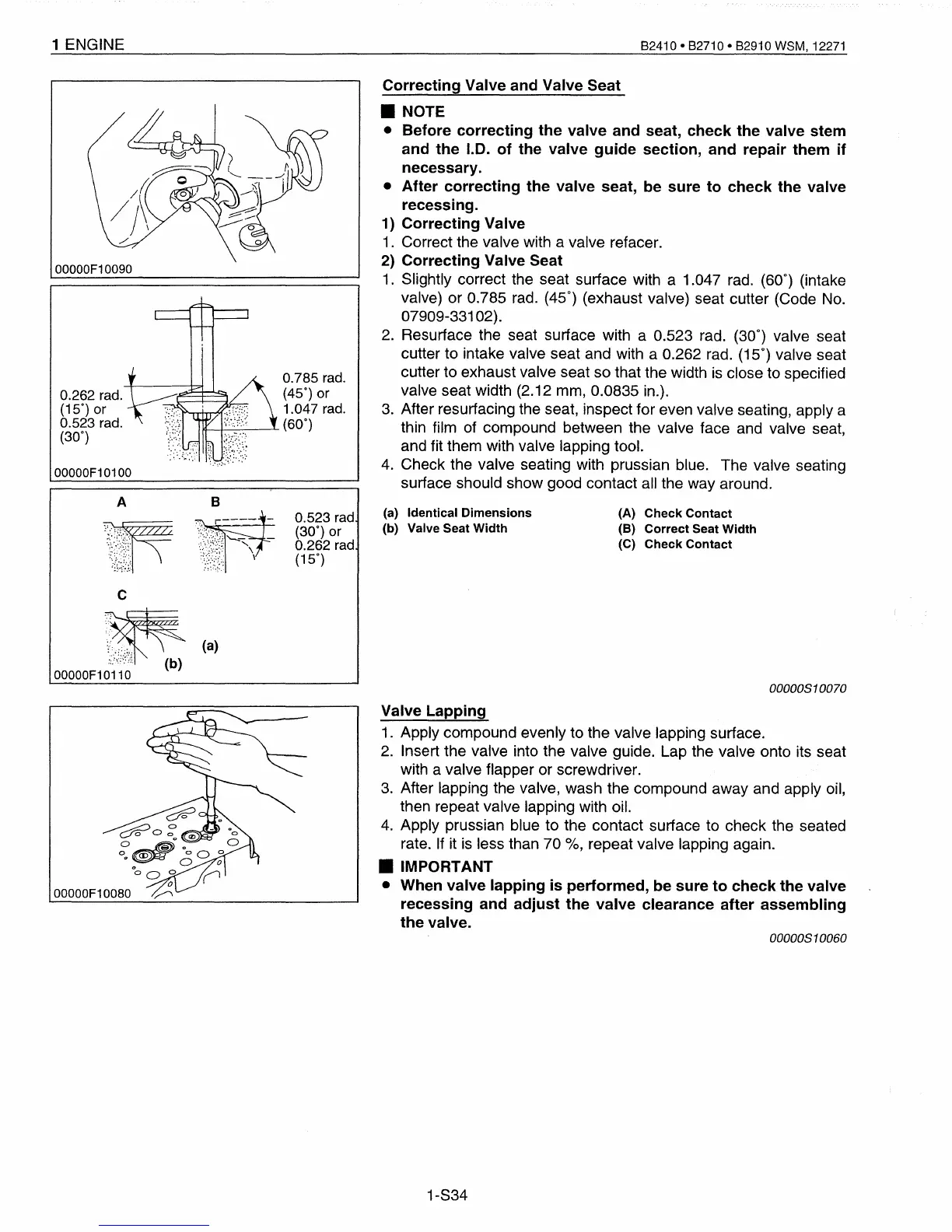

Slightly correct the seat surface with a 1.047

rad.

(60°) (intake

valve) or 0.785 rad. (45°) (exhaust valve) seat cutter (Code

No.

07909-33102).

2.

Resurface the seat surface with a 0.523 rad. (30°) valve seat

cutter to intake valve seat and with a 0.262 rad. (15°) valve seat

cutter to exhaust valve seat so that the width

is

close to specified

valve seat width (2.12 mm, 0.0835 in.).

3.

After resurfacing the seat, inspect for even valve seating, apply a

thin film of compound between the valve face and valve seat,

and fit them with valve lapping tool.

4.

Check the valve seating with prussian blue. The valve seating

surface should show good contact all the way around.

0.785 rad.

(45°)

or

1.047 rad.

114--~--'-

(60°)

0.262 rad.

(15°)

or

0.523 rad.

(30°)

A B

~p

0.523 rad

(30°) or

0.262 rad

(15°)

(a) Identical

Dimensions

(b) Valve Seat

Width

(A)

Check

Contact

(B)

Correct

Seat

Width

(C)

Check

Contact

00000810070

OOOOOF10080

Valve

Lapping

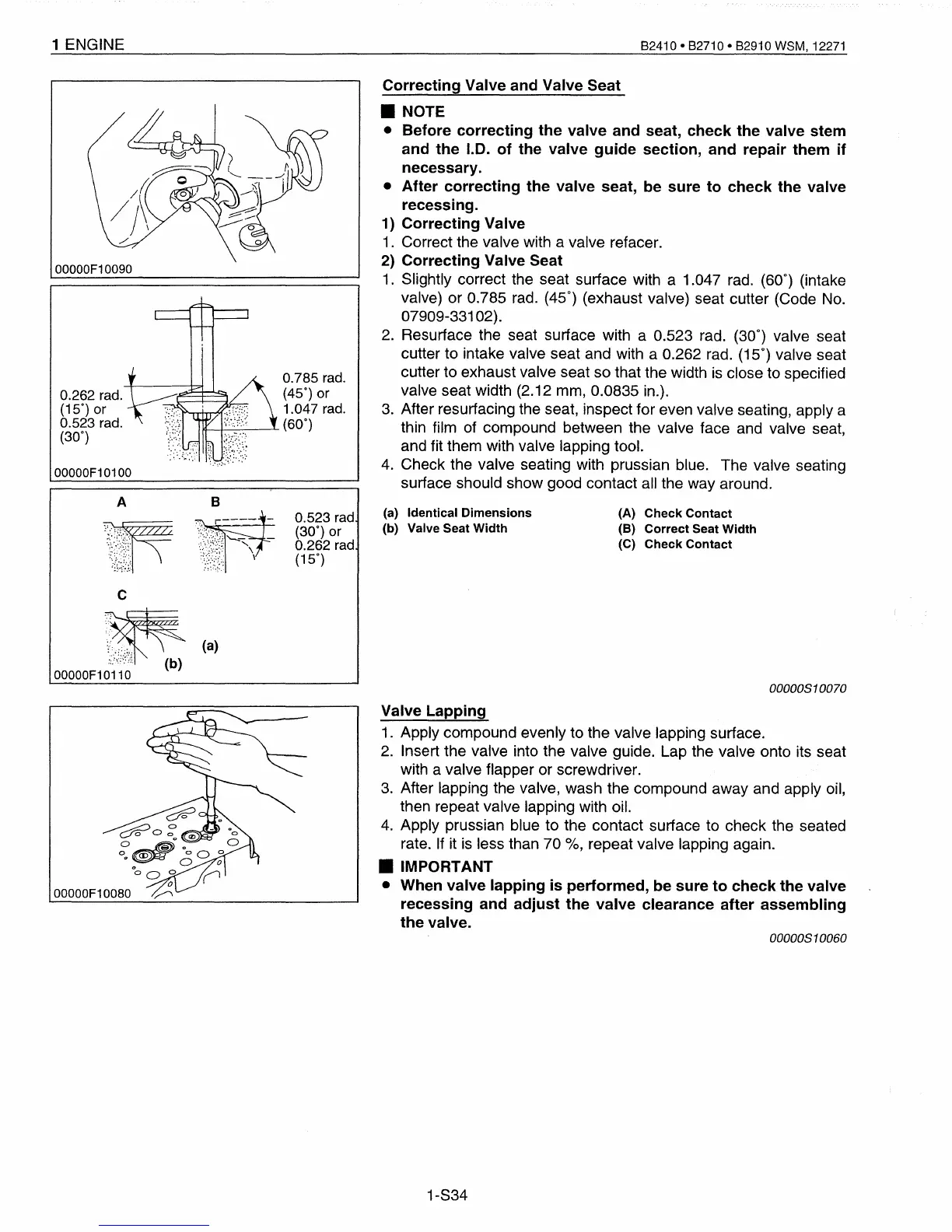

1.

Apply compound evenly to the valve lapping surface.

2.

Insert the valve into the valve guide. Lap the valve onto its seat

with a valve flapper or screwdriver.

3.

After lapping the valve, wash the compound away and apply oil,

then repeat valve lapping with oil.

4.

Apply prussian blue to the contact surface to check the seated

rate. If it

is

less than 70

0/0,

repeat valve lapping again.

• IMPORTANT

• When

valve

lapping

is

performed,

be

sure

to

check

the

valve

recessing

and

adjust

the

valve

clearance

after

assembling

the

valve.

00000810060

1-S34

Loading...

Loading...