8 HYDRAULIC

SYSTEM

82410· 82710·

82910 WSM,

12271

C

B

P:

Pump

Port

C:

Cylinder

Port

S:

Slit

T1,

T3

:Tank

Port

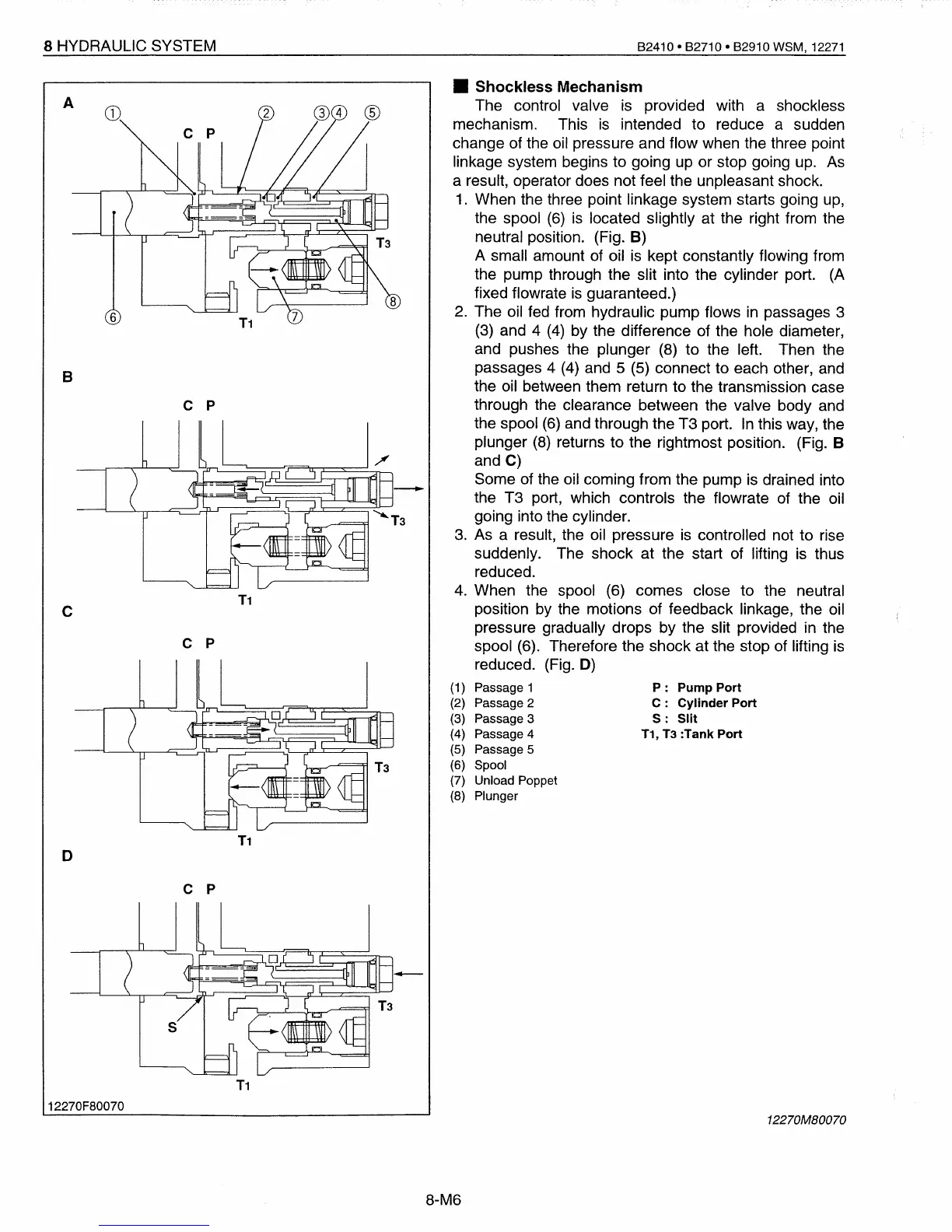

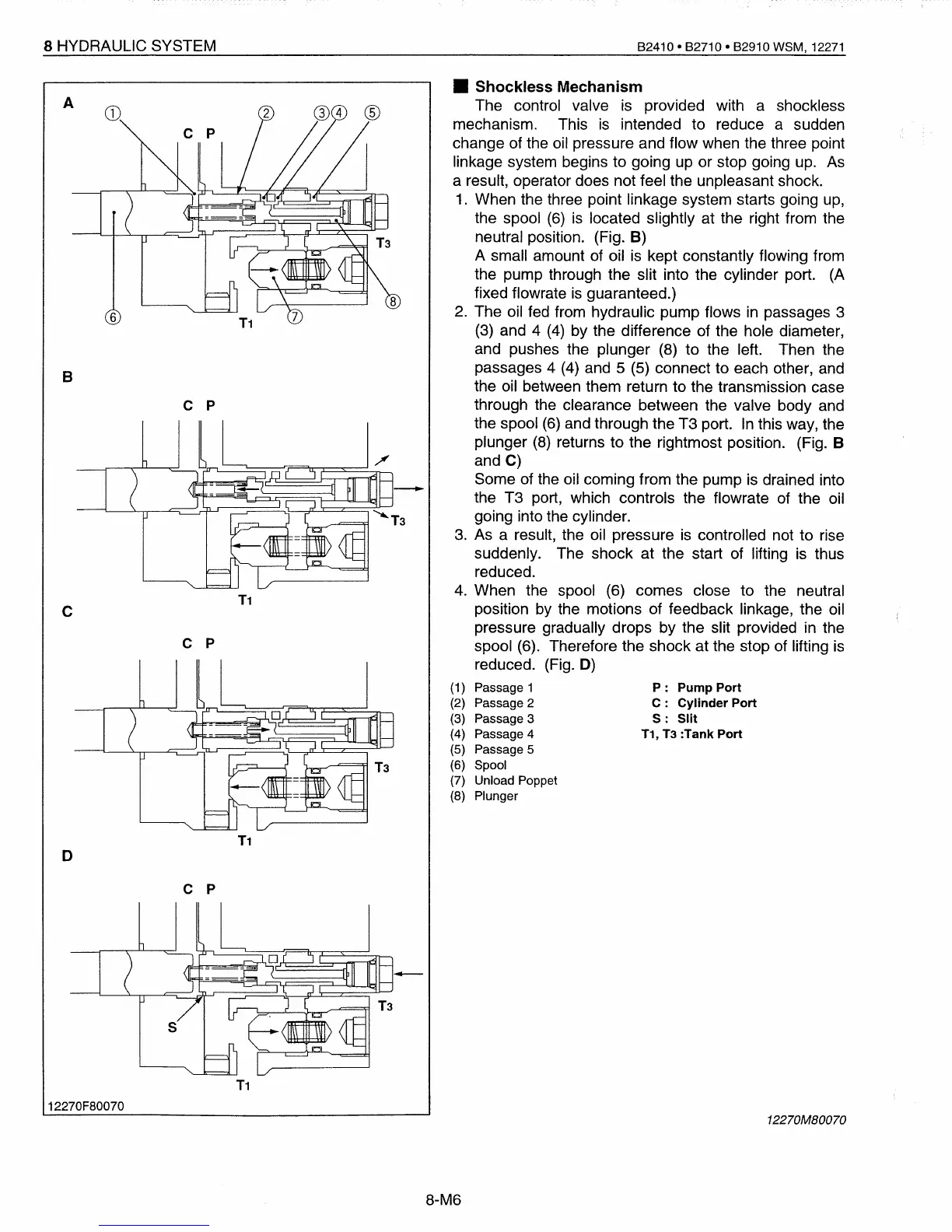

• Shockless Mechanism

The control valve

is

provided with a shockless

mechanism. This

is

intended to reduce a sudden

change of the

oil

pressure and flow when the three point

linkage system begins to going

up

or stop going

up.

As

a result, operator does not feel the unpleasant shock.

1.

When the three point linkage system starts going

up,

the spool

(6)

is

located slightly at the right from the

neutral position. (Fig. B)

A small amount of oil

is

kept constantly flowing from

the pump through the slit into the cylinder port. (A

fixed flowrate

is

guaranteed.)

2.

The oil

fed

from hydraulic pump flows

in

passages 3

(3)

and 4

(4)

by the difference of the hole diameter,

and pushes the plunger

(8)

to the left. Then the

passages 4

(4)

and 5

(5)

connect to each other, and

the oil between them return to the transmission case

through the clearance between the valve body and

the spool

(6)

and through the T3 port.

In

this way, the

plunger

(8)

returns to the rightmost position. (Fig. B

and

C)

Some of the oil coming from the pump

is

drained into

the T3 port, which controls the flowrate

of

the oil

going into the cylinder.

3.

As

a result, the oil pressure

is

controlled not to rise

suddenly. The shock at the start

of

lifting

is

thus

reduced.

4.

When the spool

(6)

comes close to the neutral

position

by

the motions of feedback linkage, the oil

pressure gradually drops by the slit provided

in

the

spool (6). Therefore the shock at the stop of lifting

is

reduced. (Fig.

D)

(1) Passage 1

(2) Passage 2

(3) Passage 3

(4) Passage 4

(5) Passage 5

(6) Spool

(7) Unload Poppet

(8) Plunger

T1

A

c p

c p

D

T1

c p

T1

12270F80070

12270MB0070

8-M6

Loading...

Loading...