GENERAL

M6060, M7060, WSM

G-93

[2] TREAD ADJUSTMENT

• When working on slopes or when working with trailer, set the wheel tread as wide as practical for

maximum stability.

• Support tractor securely on stands before removing a wheel.

• Do not work under any hydraulically supported devices. They can settle, suddenly leak down, or be

accidentally lowered. If necessary to work under tractor or any machine elements for servicing or

adjustment, securely support them with stands or suitable blocking beforehand.

• Never operate tractor with a loose rim, wheel, or axle.

9Y1210828GEG0129US0

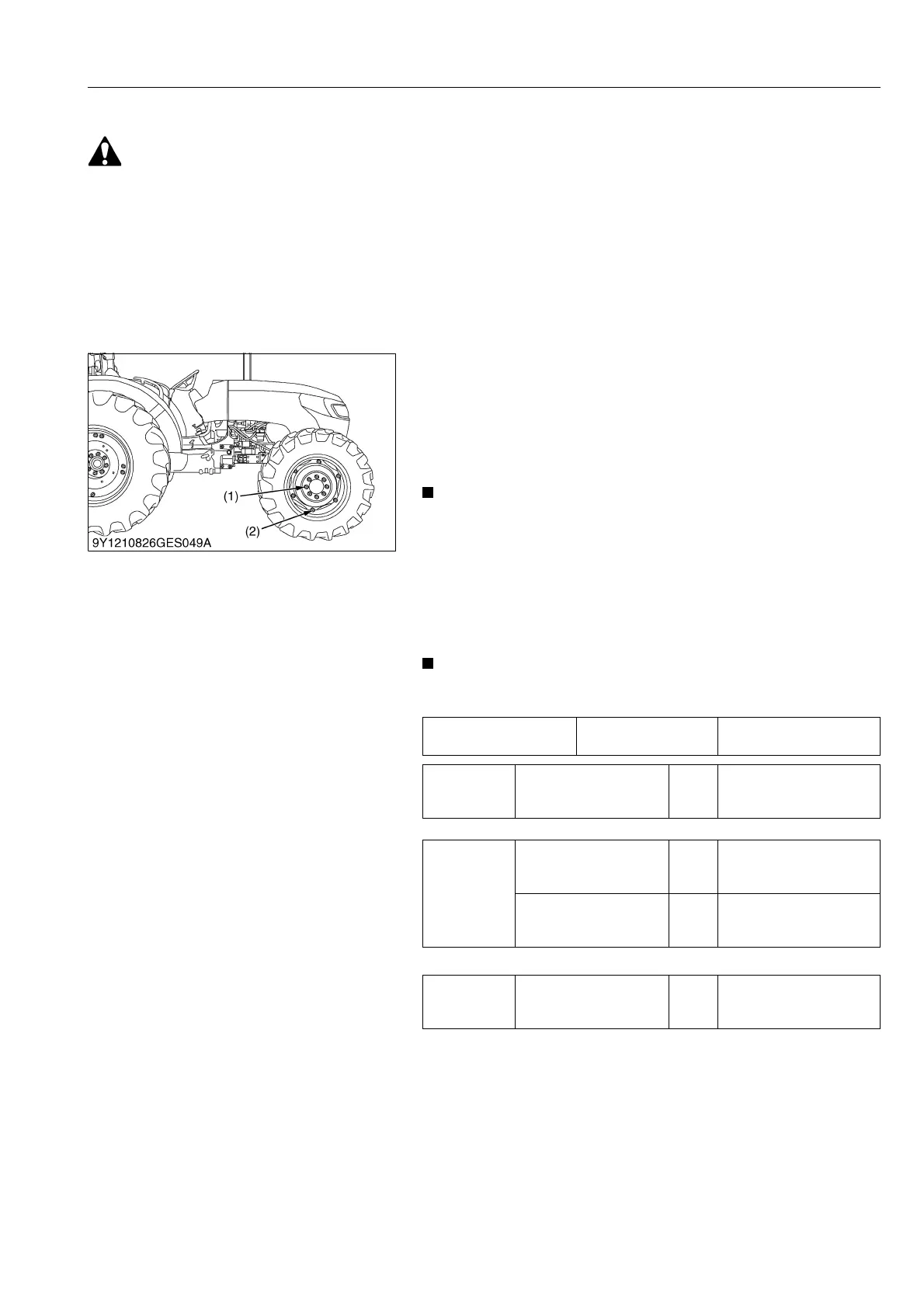

(1) Front Wheels

Front tread width can be adjusted as shown with the standard

equipped tires.

To change the tread width

1. Remove the wheel rim and disc mounting bolts.

2. Change the position of the rim and disc (right and left) to the

desired position, and tighten the bolts.

3. Adjust the toe-in. (See page G-32.)

• Always attach wheels as shown in the figure.

• If not attached as illustrated, transmission parts may be

damaged.

• When re-fitting or adjusting a wheel, tighten the bolts to the

following torques then recheck after driving the tractor 200

m (200 yards) and 10 times of shuttle movement by 5 m (5

yards), and thereafter according to service interval. (See

page G-24.)

• Wheels with beveled or tapered holes: use the tapered side

of lug nut.

Disc : Manufactured by TITAN INTERNATIONAL INC.

Disc : Other manufactured

(To be continued)

Toe-in Factory specification

2.0 to 8.0 mm

0.08 to 0.31 in.

Tightening

torque

Front wheel mounting

nut (4WD)

M16

259.9 to 304.0 N·m

26.5 to 31.0 kgf·m

191.7 to 224.2 lbf·ft

Tightening

torque

Front disc mounting nut

(waffle wheel) (4WD)

M16

298 to 366 N·m

30.4 to 37.3 kgf·m

220 to 270 lbf·ft

Front disc mounting nut

(Except waffle wheel)

(4WD)

M16

244 N·m

24.9 kgf·m

180 lbf·ft

Tightening

torque

Front disc mounting nut

(Both steel disc and cast

iron disc)

M16

259.9 to 304.0 N·m

26.5 to 31.0 kgf·m

191.7 to 224.2 lbf·ft

(1) Front Wheel Mounting Nut (2) Front Disc Mounting Nut

Loading...

Loading...