HYDRAULIC SYSTEM

M6060, M7060, WSM

7-S31

6. SERVICING

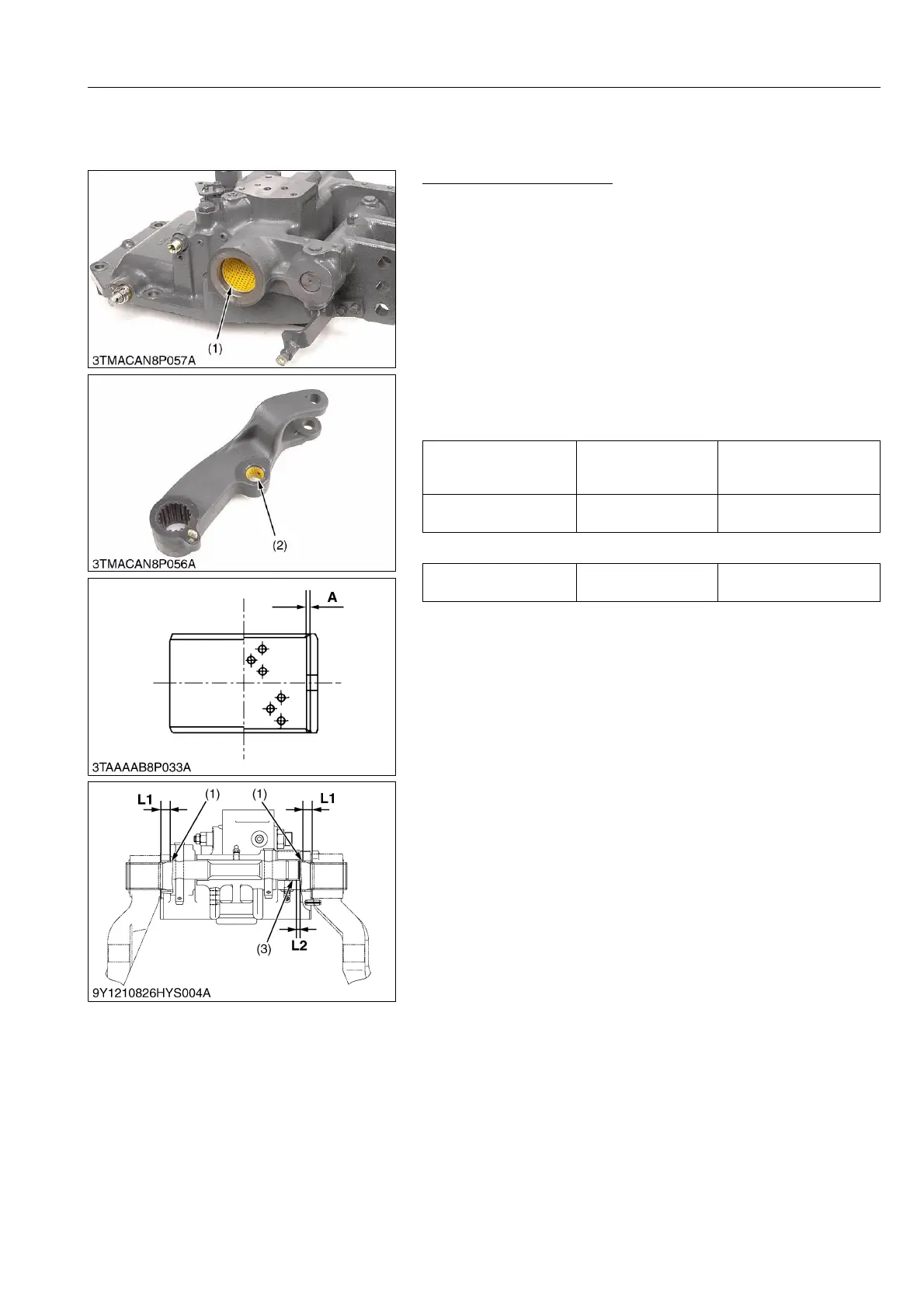

[1] LIFT ARM AND TOP LINK BRACKET

Lift Arm Support Bushing

1. Visually inspect the DX bushings for signs of wear or damage.

(The DX bushing tends to show concentrated wear.)

2. If the DX bushing is worn beyond the alloy portion (A), replace it.

(When installing)

• When press-fitting a new bushing with a press-fitting tool, see

page G-79.

• When press-fitting a new bushing, apply transmission fluid to

the lift arm support liner boss.

• When press-fitting a new bushing

– Lift arm support bushing's seam face to rear and hole face

to front and upper.

– Lift arm bushing's seam face to front and lower and hole

face to rear.

(Reference)

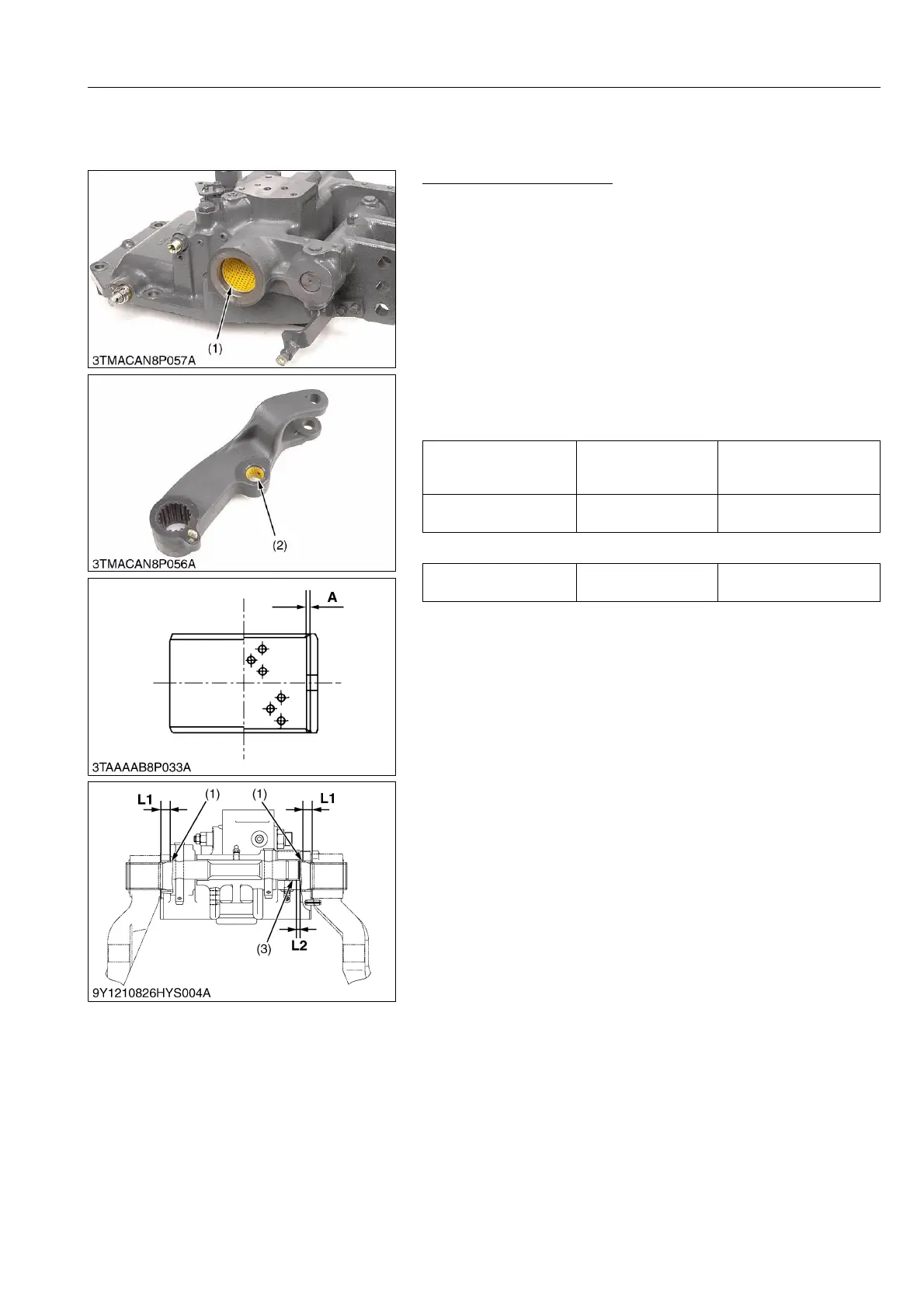

9Y1210828HYS0038US0

Press-fit location of the

lift arm support bushing

(L1)

Factory specification

15.0 mm

0.591 in.

Press-fit Location of the

Torsion Bar Bushing (L2)

Factory specification

6.0 mm

0.24 in.

Lift arm support and lift

arm bushing

Alloy thickness (A)

0.57 mm

0.0224 in.

(1) Lift Arm Support Bushing

(2) Lift Arm Bushing

(3) Torsion Bar Bushing

A : Alloy Thickness

L1 : Press-fit Location of the Lift Arm

Support Bushing

L2 : Press-fit Location of the Torsion

Bar Bushing

Loading...

Loading...