ENGINE

M6060, M7060, WSM

1-S72

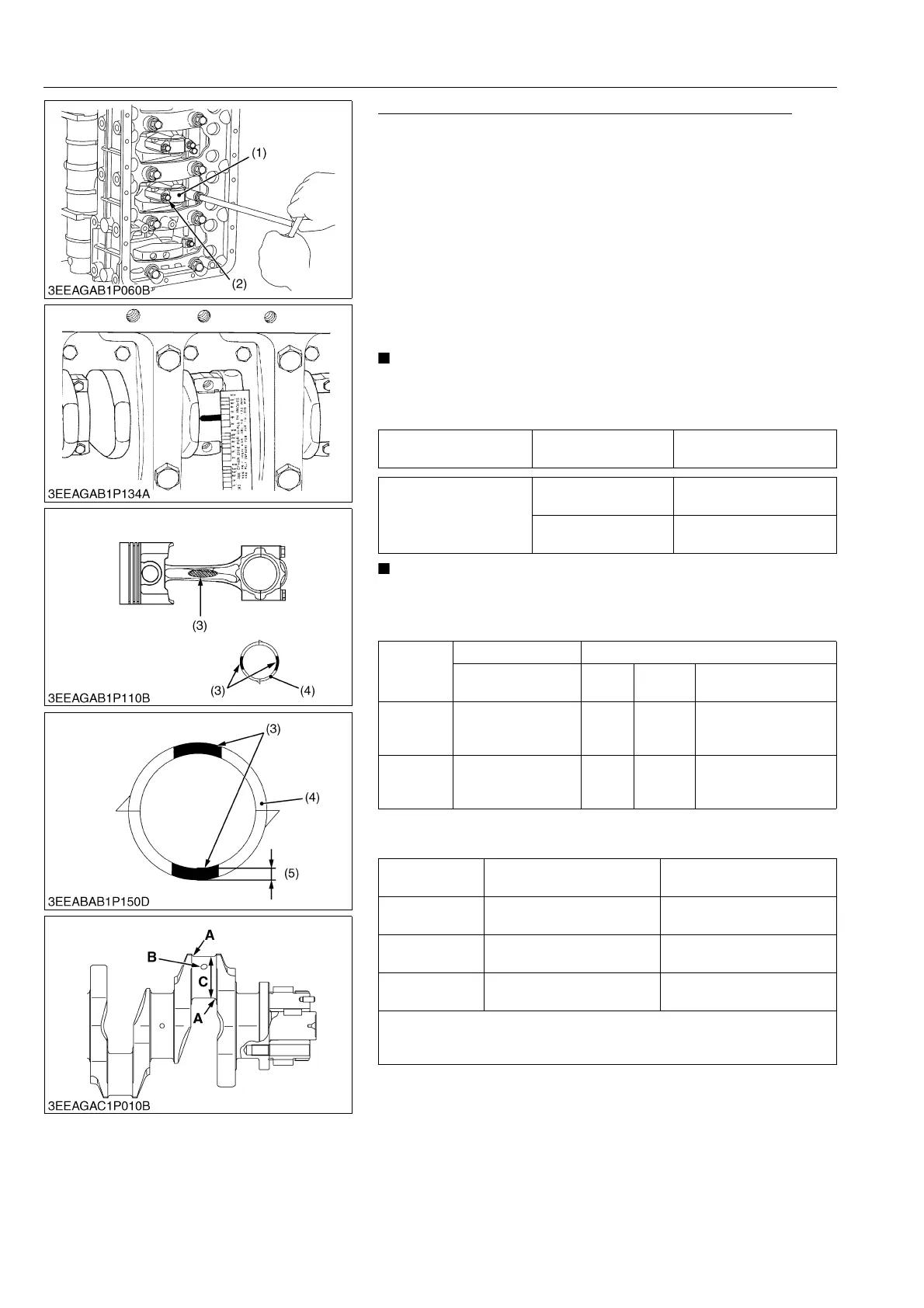

Oil Clearance between Crank Pin and Crank Pin Bearing

1. Clean the crank pin and crank pin bearing (4).

2. Put a strip of plastigauge on the center of the crank pin.

3. Install the connecting rod cap (1).

4. Tighten the connecting rod screws (2) to the specified torque.

5. Remove the connecting rod cap again.

6. Measure the width that it becomes flat with the scale to get the

oil clearance.

7. If the oil clearance is more than the allowable limit, replace the

crank pin bearing (4).

8. If the same dimension bearing is not applicable because of the

crank pin wear, replace it with an undersize one. Refer to the

table and figure.

• Do not put the Plastigauge into the crank pin oil hole.

• When you tighten the connecting rod screws (2), do not

move the crankshaft.

• To replace it with a specific STD service part, make sure the

crank pin bearing (4) has the same ID color (3) as the

connecting rod.

(Reference)

• Undersize dimensions of crank pin

9Y1210828ENS0113US0

Crank pin O.D. Factory specification

49.980 to 49.991 mm

1.9678 to 1.9681 in.

Oil clearance between

crank pin and crank pin

bearing

Factory specification

0.017 to 0.048 mm

0.00067 to 0.0018 in.

Allowable limit

0.20 mm

0.0079 in.

ID Color

Connecting rod Crank pin bearing

Large-end in. dia. Class

Part

code

Center wall thick

Blue

53.010 to

53.020 mm

2.0870 to 2.0874 in.

L

1G772-

22310

1.496 to 1.501 mm

0.05890 to 0.05909 in.

Without

color

53.000 to

53.010 mm

2.0867 to 2.0870 in.

S

1G772-

22330

1.491 to 1.496 mm

0.05870 to 0.05889 in.

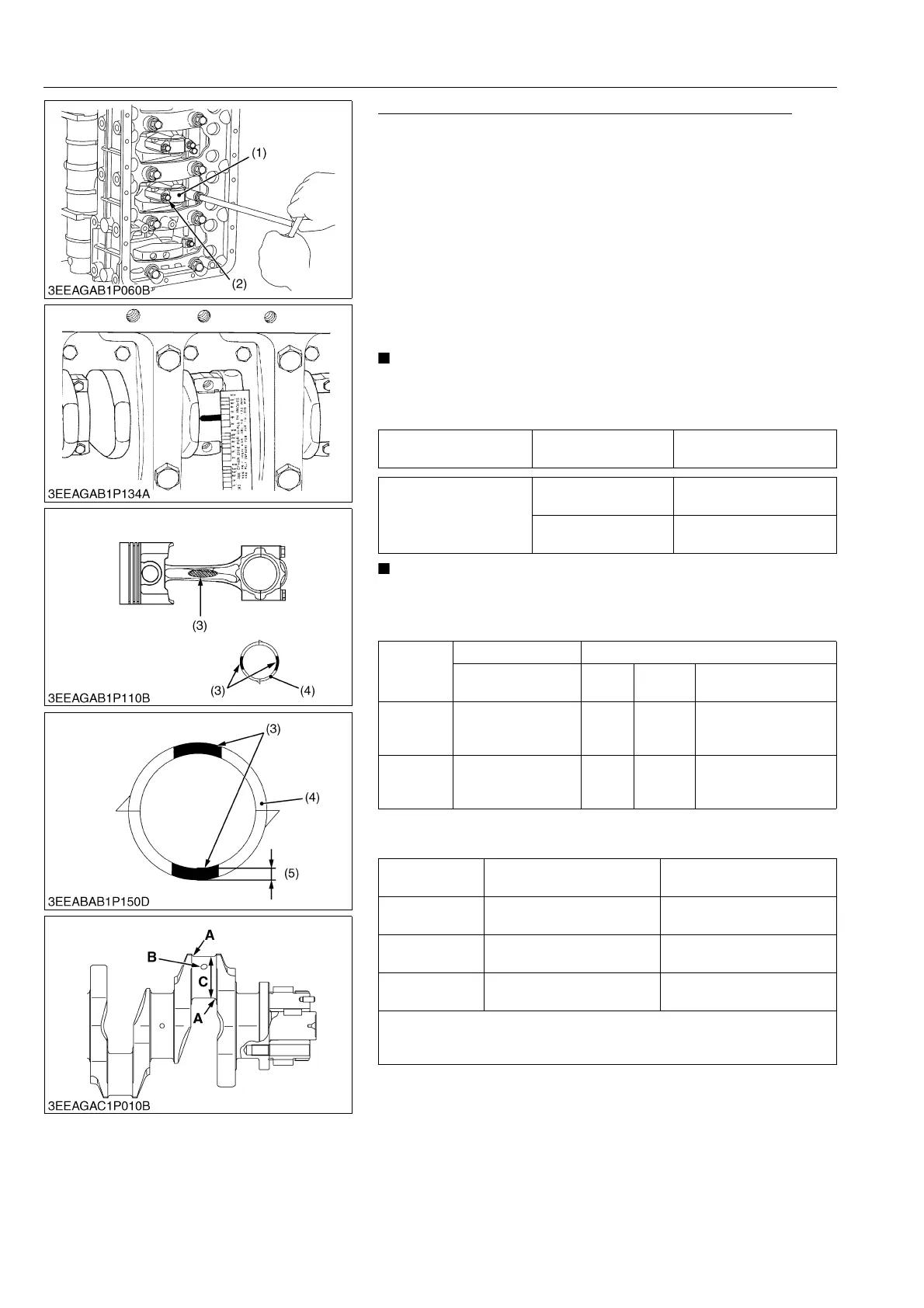

Undersize

0.2 mm

0.008 in.

0.4 mm

0.02 in.

Dimension A

3.3 to 3.7 mm radius

0.13 to 0.14 in. radius

3.3 to 3.7 mm radius

0.13 to 0.14 in. radius

*Dimension B

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

Dimension C

49.780 to 49.791 mm dia.

1.9599 to 1.9602 in. dia.

49.580 to 49.591 mm dia.

1.9520 to 1.9524 in. dia.

The crank pin must be fine-finished to higher than Rmax = 0.8S

*Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.040 to 0.059 in.) relief.

(1) Connecting Rod Cap

(2) Connecting Rod Screw

(3) ID Color

(4) Crank Pin Bearing

(5) Center Wall Thick

Loading...

Loading...