190-01115-01 G3X/G3X Touch Installation Manual - GPS/XM Antenna Installation

Rev. AC Page 22-9

22.4 Teardrop Footprint Antenna Installation (GA 35, GA 55, and GA 56)

This section describes the structural mounting of the teardrop footprint antenna installation.

An acceptable installation method is to use Garmin P/N: 115-00846-10 doubler plate with the GA 35

through-hole, or GA 55/GA 56 stud mount antennas. Another acceptable method is to fabricate and install

one of three doublers (Figure 22-4

, Figure 22-5, and Figure 22-6), depending on the thickness of the skin.

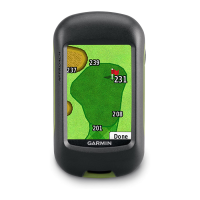

The three doubler designs vary only by number of rivets and hole preparation for installation with flush

rivets. Table 22-5 provides a summary of design and installation details for selecting the appropriate

antenna doubler/backplate.

Figure 22-7

shows an example of the doubler installed between stringers on the top fuselage skin, just off

centerline. The location should be flat, with no gaps between the skin and doubler, to keep from deforming

the skin during installation.

Refer to the drawings in Section 22.7

for Garmin Antenna installation drawings.

22.4.1 Preparation of Doubler

1. Use Garmin P/N: 115-00846-10, or refer to Table 22-5 for guidance on selecting the appropriate

doubler drawing based on the thickness of skin at the antenna location. Make the doubler from

2024-T3 Aluminum (AMS-QQ-A-250/5), 0.063” sheet thickness.

2. For installation in aircraft skins of thickness less than 0.051”, countersink the rivet holes in the

doubler for use with flush head rivets (MS20426AD4-x).

3. When using Garmin P/N: 115-00846-10 doubler, sixteen rivet holes exist in the part. For

installation of Garmin P/N: 115-00846-10 in skins of thickness between 0.032” and 0.049”, only

the rivets identified for use through the skin cutout detail (Figure 22-8

) and doubler installation

(Figure 22-11

) are required.

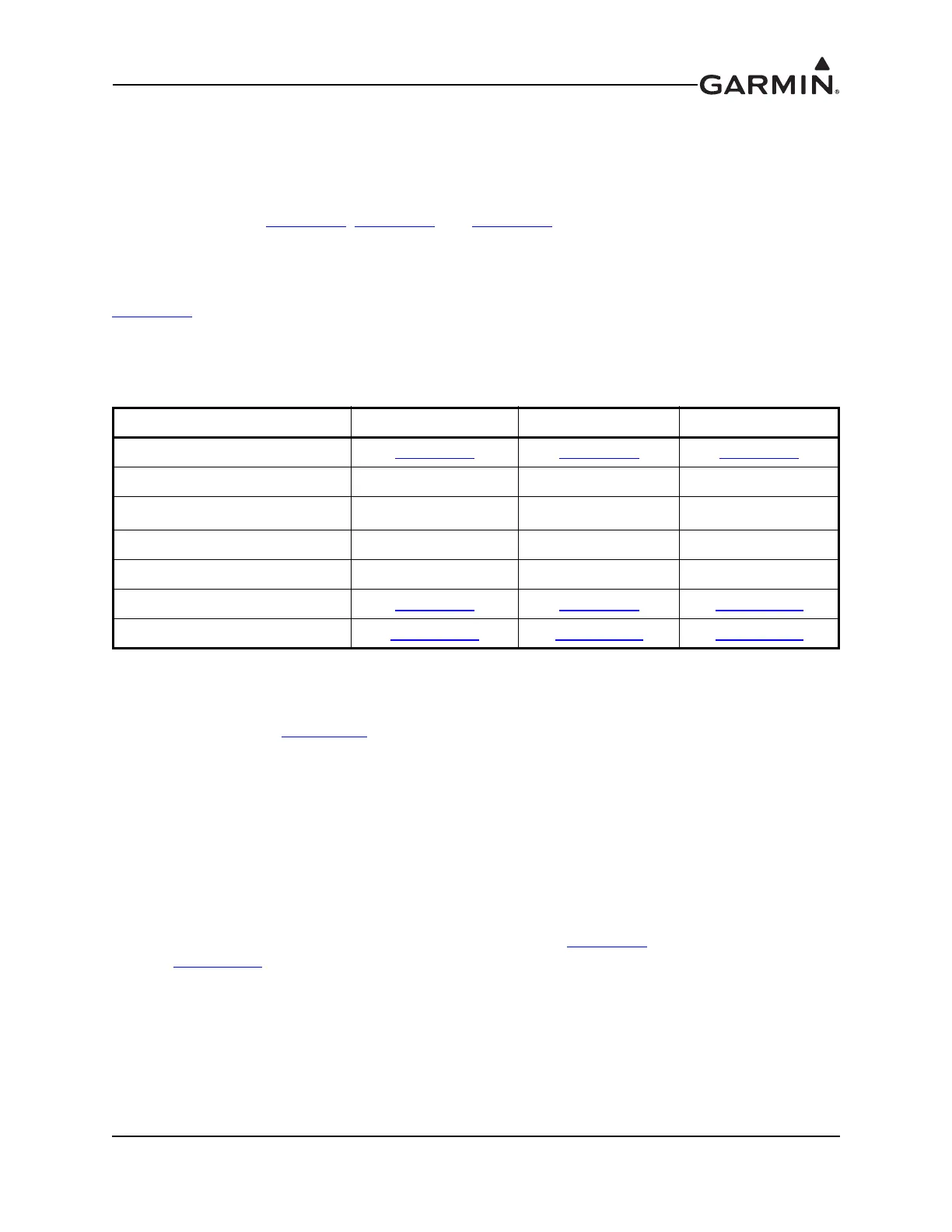

Table 22-5 Teardrop Footprint Antenna Doubler Design and Installation

Aircraft Skin Thickness 0.032” to 0.049” 0.049” to 0.051” 0.051” to 0.063”

Doubler Design (Figure) Figure 22-4 Figure 22-5 Figure 22-6

Number of Rivets Required 12 16 16

Type of Rivets Required

1

MS20426AD4-x MS20426AD4-x MS20426AD4-x

Skin Preparation for Rivets Dimple Dimple Countersink

Doubler Preparation for Rivets Countersink Countersink None

Skin Cutout Detail (Figure) Figure 22-8 Figure 22-9 Figure 22-10

Doubler Installation (Figure) Figure 22-11 Figure 22-12 Figure 22-13

1

Rivet length determined at installation, dependent on thickness of material (rivet length = grip length +

1.5 * rivet diameter)

Loading...

Loading...