85320

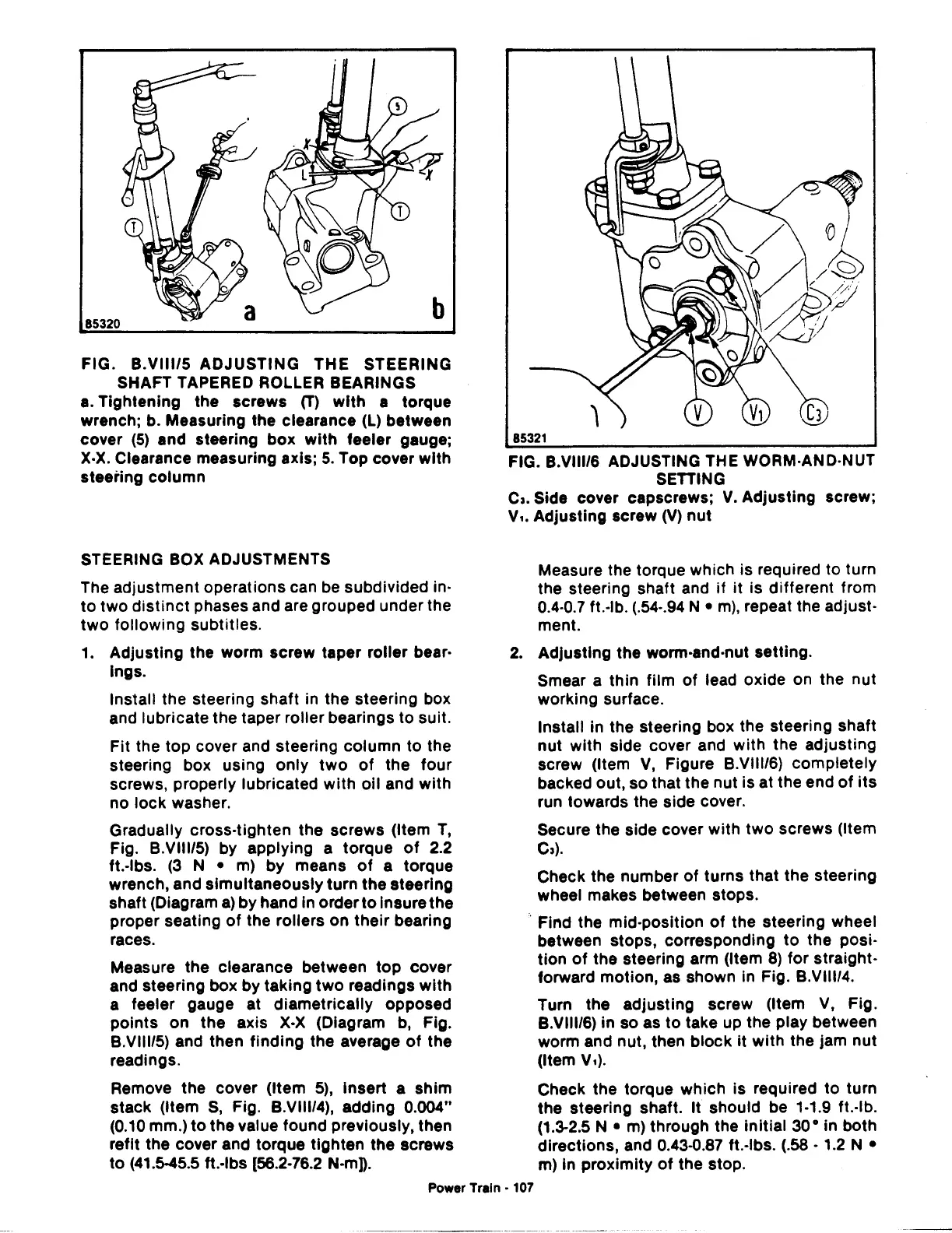

FIG. B.VIII/5 ADJUSTING THE STEERING

SHAFT TAPERED ROLLER BEARINGS

a.

Tightening the screws (T)

with

a torque

wrench; b. Measuring the clearance

(L)

between

cover

(5)

and steering box

with

feeler gauge;

X·X.

Clearance measuring axis;

5.

Top cover with

steering column

STEERING BOX ADJUSTMENTS

The adjustment operations can be subdivided in·

to

two

distinct

phases and are grouped under the

two

following subtitles.

1.

Adjusting the worm screw taper roller bear·

lngs.

Install the steering shaft in the steering box

and lubricate the taper roller bearings

to

suit.

Fit the top cover and steering column to the

steering box using only

two

of

the four

screws, properly lubricated with oil and with

no lock washer.

Gradually cross-tighten the screws (Item

T,

Fig. B.VIII/5) by applying a torque

of

2.2

ft.-lbs.

(3

N •

m)

by means

of

a torque

wrench, and simultaneously turn the steering

shaft (Diagram

a)

by hand In order

to

Insure the

proper seating

of

the rollers on their bearing

races.

Measure the clearance between

top

cover

and steering box by taking

two

readings with

a feeler gauge at diametrically opposed

points on the axis

X·X

(Diagram b, Fig.

B.VIII/5) and then finding the average

of

the

readings.

Remove the cover (Item

5),

insert a shim

stack (Item

S,

Fig. B.VIII/4), adding 0.004"

(0.10

mm.)

to

the value found previously, then

refit the cover and torque tighten the screws

to

(41.5-45.5

ft.·lbs [56.2·76.2

N-mD.

85321

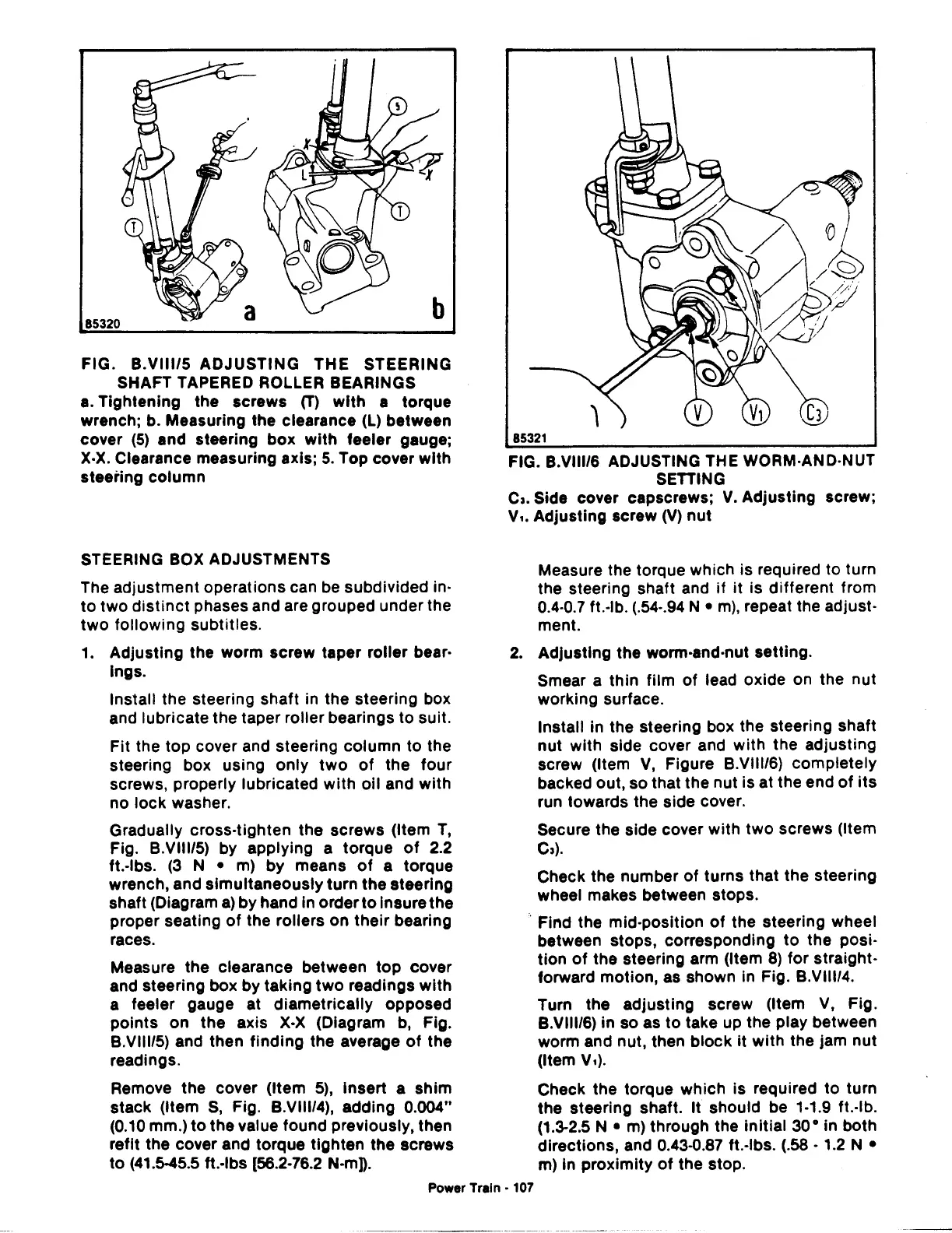

FIG. B.VIII/6 ADJUSTING THE WORM·AND-NUT

SETTING

Ca.

Side cover capscrews;

V.

Adjusting screw;

v,.

Adjusting screw

(V)

nut

Measure the torque which is required to turn

the steering shaft and if it is different from

0.4·0.7 ft.-lb.

(.54-.94

N •

m),

repeat the adjust-

ment.

2.

Adjusting the worm-and-nut setting.

Smear a thin film

of

lead oxide on the nut

working surface.

Install in the steering box the steering shaft

nut with side cover and with the adjusting

screw (Item

V,

Figure B.VIII/6) completely

backed out, so that the nut is at the end

of

its

run towards the side cover.

Secure the side cover with two screws (Item

Ca).

Check the number

of

turns that the steering

wheel makes between stops.

Find the mid-position

of

the steering wheel

between stops, corresponding

to

the posi·

tion

of

the steering arm (Item

8)

for straight·

forward motion, as shown in Fig. B.VIII/4.

Turn the adjusting screw (Item

V,

Fig.

B.VIII/6) in so as

to

take up the play between

worm and nut, then block

it

with the jam nut

(Item V,).

Check the torque which is required to turn

the steering shaft. It should be 1·1.9 ft.-lb.

(1.3-2.5

N •

m)

through the initial

30

• in both

directions, and 0.43-0.87 ft.-lbs.

(.58·

1.2

N •

m)

In

proximity

of

the stop.

Power Train • 107

Loading...

Loading...