25290

Dr·-

-Qc.

•QZ

1---i------!lS

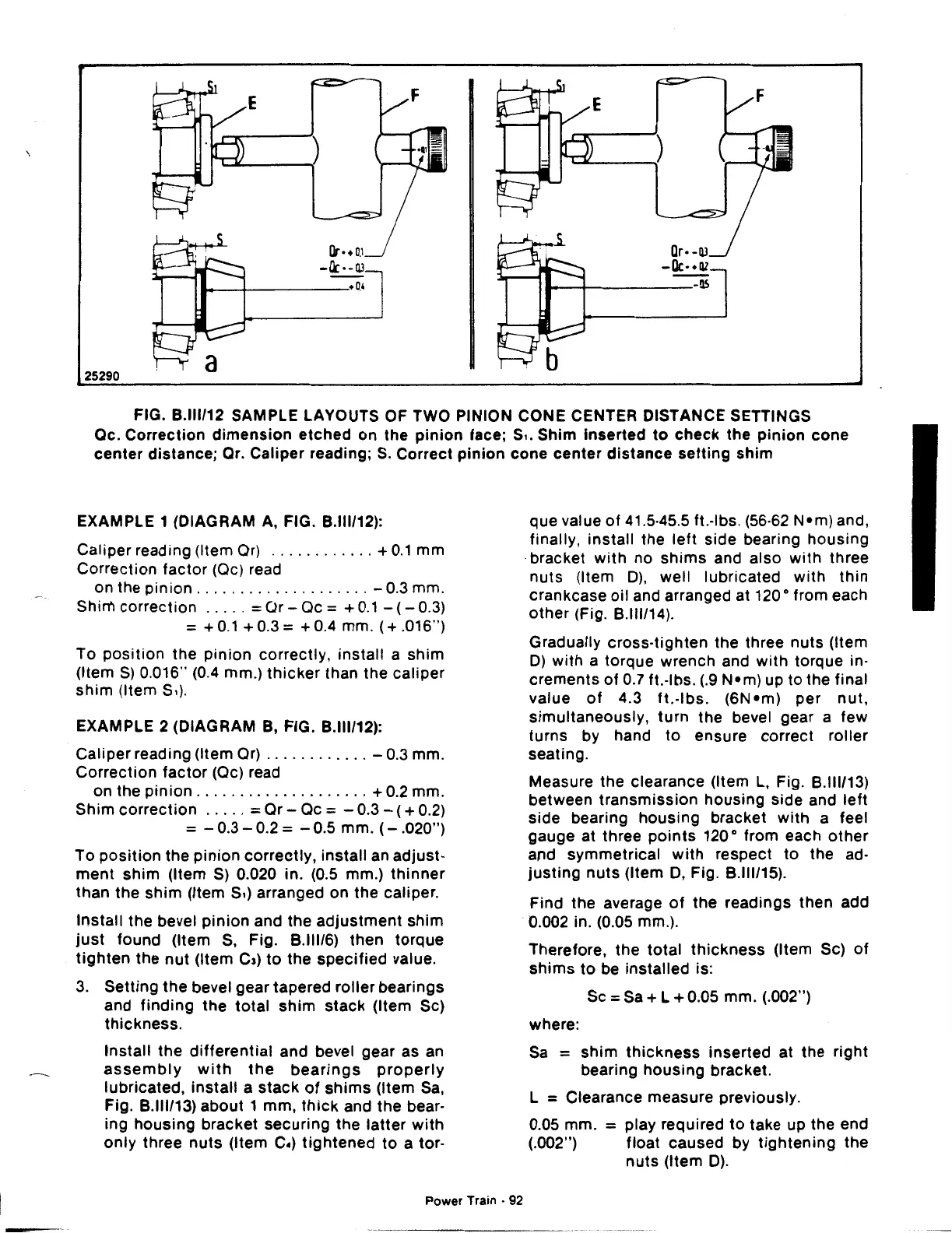

FIG.

8.111112

SAMPLE LAYOUTS OF TWO PINION CONE CENTER DISTANCE SETTINGS

Oc. Correction

dimension

etched

on the

pinion

face; s

..

Shim

inserted

to

check

the

pinion

cone

center

distance; Or. Caliper reading;

S.

Correct

pinion

cone

center

distance

setting

shim

EXAMPLE 1 (DIAGRAM A, FIG.

8.111112):

Caliper reading (Item Or)

............

+

0.1

mm

Correction factor (Oc) read

on the

pinion

....................

-0.3

mm.

Shim correction

.....

= CJr- Oc = +

0.1

-

(-

0.3)

= +0.1

+0.3=

+0.4

mm.

(+.016")

To

position

the

pinion

correctly, install a shim

(Item

S)

0.016" (0.4 mm.)

thicker

than the

caliper

shim

(Item S.).

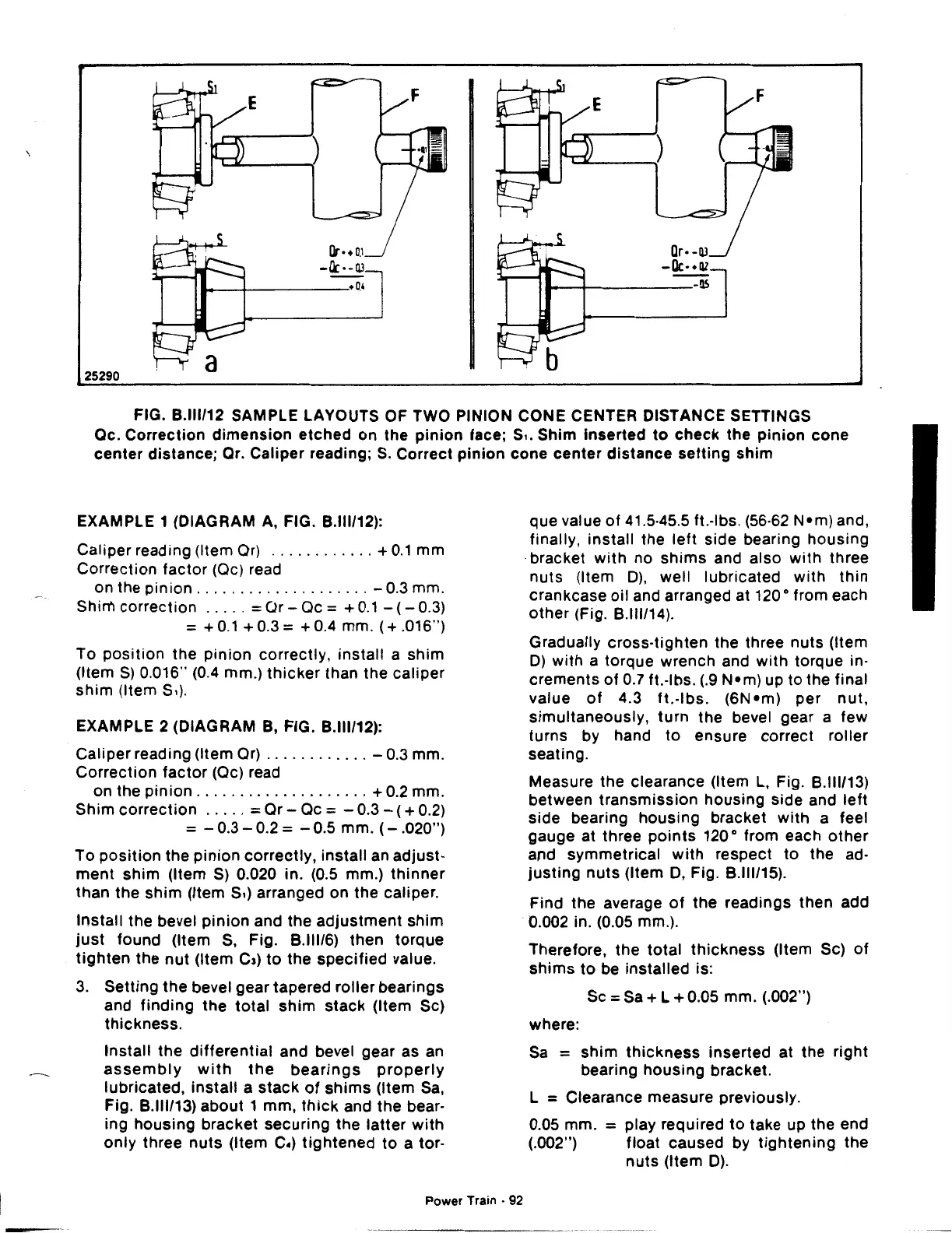

EXAMPLE 2 (DIAGRAM

8,

FIG.

8.111112):

Caliper reading (Item Or)

............

-0.3

mm.

Correction

factor

(Oc) read

on the

pinion

....................

+ 0.2 mm.

Shim

correction

.....

=Or-

Oc = -

0.3-

( + 0.2)

= -

0.3-

0.2 =

-0.5

mm.

(-

.020")

To

position

the

pinion

correctly,

install an

adjust·

ment

shim

(Item

S)

0.020 in. (0.5 mm.)

thinner

than the

shim

(Item

s,)

arranged on the caliper.

Install the bevel

pinion

and the

adjustment

shim

just

found (Item

S,

Fig.

8.11116)

then torque

tighten

the

nut

(Item

c,)

to

the

specified

value.

3.

Setting

the

bevel gear tapered

roller

bearings

and

finding

the

total

shim

stack

(Item Sc)

thickness.

Install

the

differential

and bevel gear as

an

assembly

with

the

bearings

properly

lubricated,

install

a

stack

of

shims

(Item

Sa,

Fig.

8.111113)

about

1 mm,

thick

and the bear-

ing

housing

bracket

securing

the

latter

with

only

three

nuts

(Item

c.)

tightened

to

a tor-

Power Train ·

92

que value

of

41.5·45.5 ft.·lbs. (56·62

N•m)

and,

finally, install the

left

side bearing

housing

·bracket

with

no

shims

and also

with

three

nuts

(Item

D),

well lubricated

with

thin

crankcase oil and arranged at 120 o from each

other

(Fig.

8.111114).

Gradually cross·tighten the three nuts (Item

D)

with

a torque wrench and

with

torque in·

crements

of

0.7 ft.·lbs.

(.9

N•m)

up to the final

value

of

4.3

ft.·lbs.

(6N•m)

per

nut,

simultaneously,

turn

the bevel gear a few

turns by hand

to

ensure correct roller

seating.

Measure the clearance (Item

L,

Fig.

8.111113)

between

transmission

housing

side and

left

side bearing housing bracket

with

a feel

gauge at three

points

120 o from each

other

and symmetrical

with

respect

to

the ad·

justing

nuts

(Item

D,

Fig.

8.111115).

Find the average

of

the readings then add

0.002 in. (0.05 mm.).

Therefore,

the

total

thickness

(Item Sc)

of

shims

to

be installed is:

Sc

=Sa+

L + 0.05 mm. (.002")

where:

Sa

=

shim

thickness

inserted at the right

bearing

housing

bracket.

l = Clearance measure previously.

0.05 mm.

= play required

to

take up the end

(.002") float caused by

tightening

the

nuts

(Item

D).

Loading...

Loading...