ASSEMBLING THE WHEEL HUB

Press

into

the wheel hub

(10)

the tapered roller

bearing

outer

races

(9

and

11

).

Fill

with

lithium

- base

lubricant

grease

the

hub

inside between

the

two

bearings

prior

to

mounting

on

the

flange

the

outer

tapered roller bearing inner race.

ADJUSTMENT OF WHEEL HUB BEARINGS

Tighten the first splined

nut

(Item S11, Fig.

B.IX/10) by

continuous

rotation

of

the

hub

in both

directions

until

feeling a

slight

braking; then

screw back the splined nut in order to permit a

free rotation

of

the hub

without

any play. Bend a

washer edge

(7)

into

one groove

of

the nut and

tighten

the second splined nut at a torque of

362·434 ft. lbs. (491-588 N-m).

Introduce inside

lithium

base lubricant grease.

REMARKS: The

two

splined nuts

must

be

fitted

having

the

outer chamfering towards

the bearings, as indicated on Fig.

B.IX/1

1.

Fit the splined hub

(6)

by tightening the screws

with

self-locking at a torque

of

65·72

ft.lbs.

(88-98

N-m).

Repeat the procedure for the left side.

SETTING THE FRONT DRIVE AXLE

Fit the driving wheels,

completely

assembled

with

transversal drag link.

Tighten the self-locking

nuts

and the universal

shaft

coupling

flange retaining screws at a tor-

que value

of

36·40 ft. lbs. (49·54 N-m).

Fill the casing

with

oil

by the plug (T, Fig. B.IX/3).

When carrying out

the

assembling operations,

repeat the reverse procedure as indicated for

removal.

After

finishing

the reassembling, grease the

splined

joint

and

the

universal

joint

until

the

grease leaks out by the universal

joint

central

trap. To carry

out

this

operation use a grease

gun.

RUNNING-IN OF THE FRONT DRIVE AXLE

Grease

with

lubricant

grease the

joint

locations

through

the

threaded plug holes provided

with

sealing rings.

Tighten

the

greasers

into

the

wheel

hubs

and

steering levers.

Fill the

differential

casing

with

the recommend-

ed

oil

up

to

the

level

of

the plug.

Fit

on

the

running-in bench the front driver axle

and

let

it

operate for 5

minutes

at a speed

of

1800

rpm.

At

the

same time, check for:

abnormal noise exceeding the medium level.

oil

leakages at

joints

and seatings.

abnormal heating

of

the moving parts.

if

the hub presents a

slight

vibration within

the permitted angle by the stop plates.

INSPECTION

Make sure that the nuts

anQ

the screws from the

above-mentioned table are tightened to the tor·

que

specification

and that they are secured.

Make sure the running-in period of 5

minutes

is

carried out; during the running-in the front drive

axle

must

strictly

comply

with

as

follows:

front

drive axle must not get hot;

front

drive axle

must

not

present abnormal

noise;

no leakages are permitted;

the steering levers

must

easily rotate:

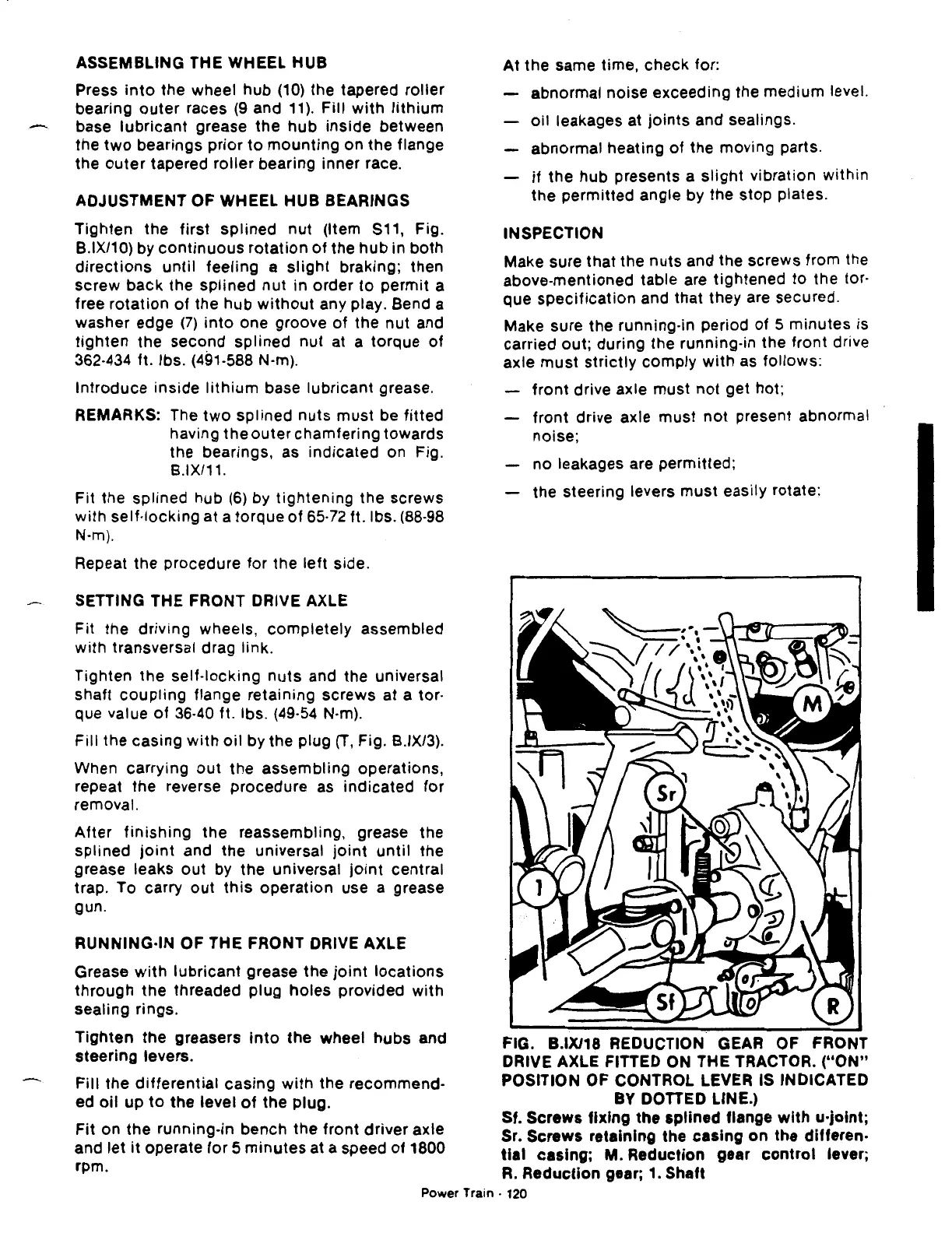

FIG. B.IX/18 REDUCTION GEAR OF FRONT

DRIVE AXLE FITTED

ON

THE TRACTOR.

("ON"

POSITION OF CONTROL LEVER IS INDICATED

BY DOTTED LINE.)

Sf. Screws fixing the

splined

flange

with

u-joint;

Sr. Screws retaining the casing on the differen·

tial

casing; M. Reduction gear

control

lever;

R.

Reduction gear;

1.

Shaft

Power Train · 120

Loading...

Loading...