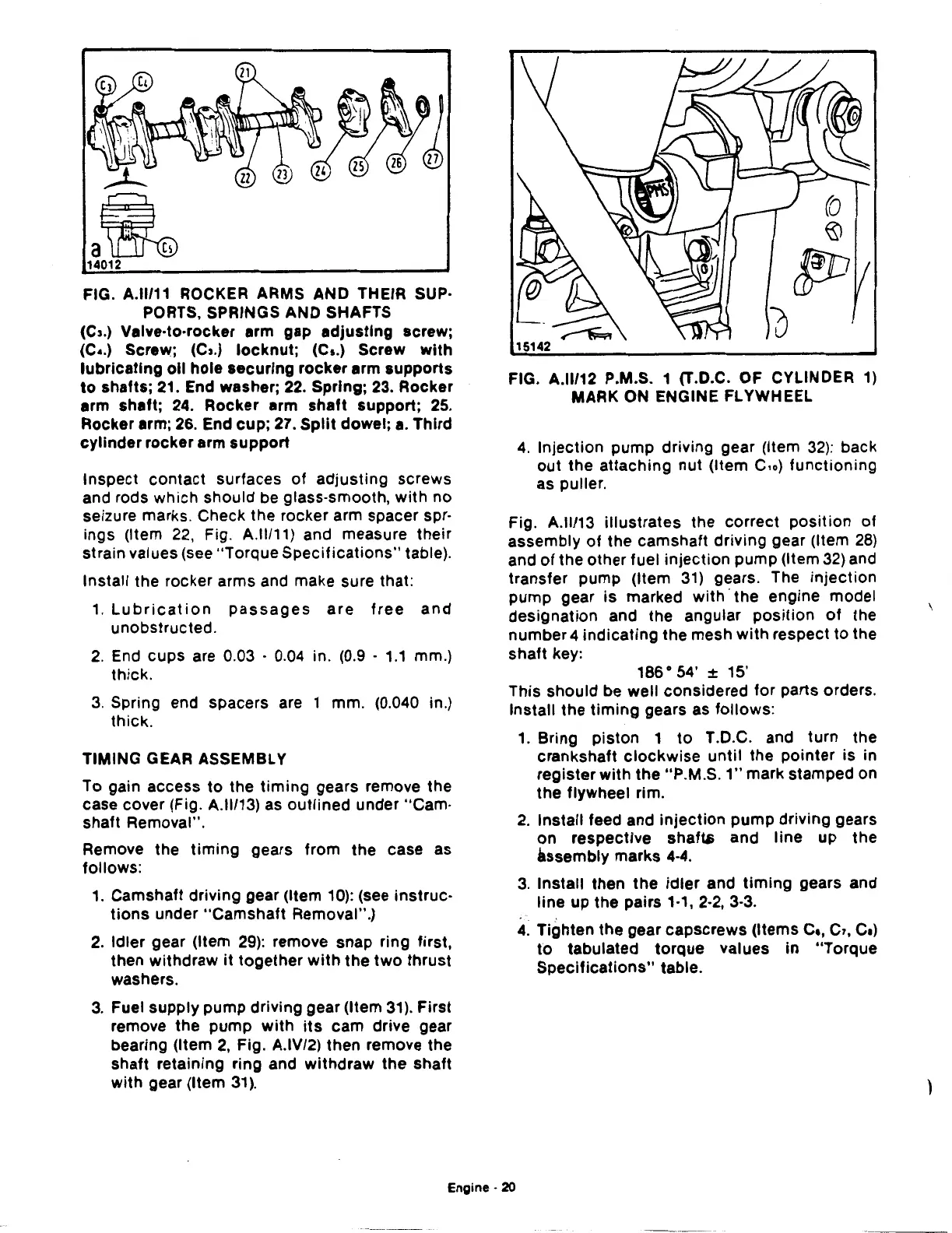

FIG. A.ll/11 ROCKER ARMS AND THEIR SUP·

PORTS, SPRINGS AND SHAFTS

(C,.) Valve-to-rocker arm gap

adjusting

screw;

(C

•.

) Screw; (C,.)

locknut;

(Ca.)

Screw

with

lubricating

oil

hole securing rocker arm supports

to

shafts;

21.

End washer;

22.

Spring;

23.

Rocker

arm shaft; 24. Rocker arm

shaft

support;

25.

Rocker arm;

26.

End cup;

27.

Split

dowel;

a.

Third

cylinder

rocker arm

support

Inspect contact surfaces

of

adjusting

screws

and rods which should be glass-smooth,

with

no

seizure marks. Check the rocker arm spacer spr-

ings (Item

22,

Fig. A.ll/1

1)

and measure

their

strain values (see "Torque

Specifications"

table).

Install the rocker arms and make sure that:

1.

Lubrication

passages

are

free

and

unobstructed.

2.

End cups are 0.03 -

0.04

in.

(0.9

·

1.1

mm.)

thick.

3.

Spring end spacers are 1 mm. (0.040 in.)

thick.

TIMING GEAR ASSEMBLY

To gain access

to

the

timing

gears remove the

case cover (Fig. A.ll/13) as

outlined

under "Cam-

shaft Removal".

Remove the

timing

gears from the case as

follows:

1.

Camshaft driving gear (Item

10):

(see

instruc·

tions

under

"Camshaft

Removal".)

2.

Idler gear (Item

29):

remove snap ring first,

then withdraw

it

together

with

the

two

thrust

washers.

3.

Fuel supply pump driving gear (Item

31).

First

remove the pump

with

its

cam drive gear

bearing (Item

2,

Fig. A.IV/2) then remove the

shaft retaining ring and

withdraw

the shaft

with

gear (Item

31).

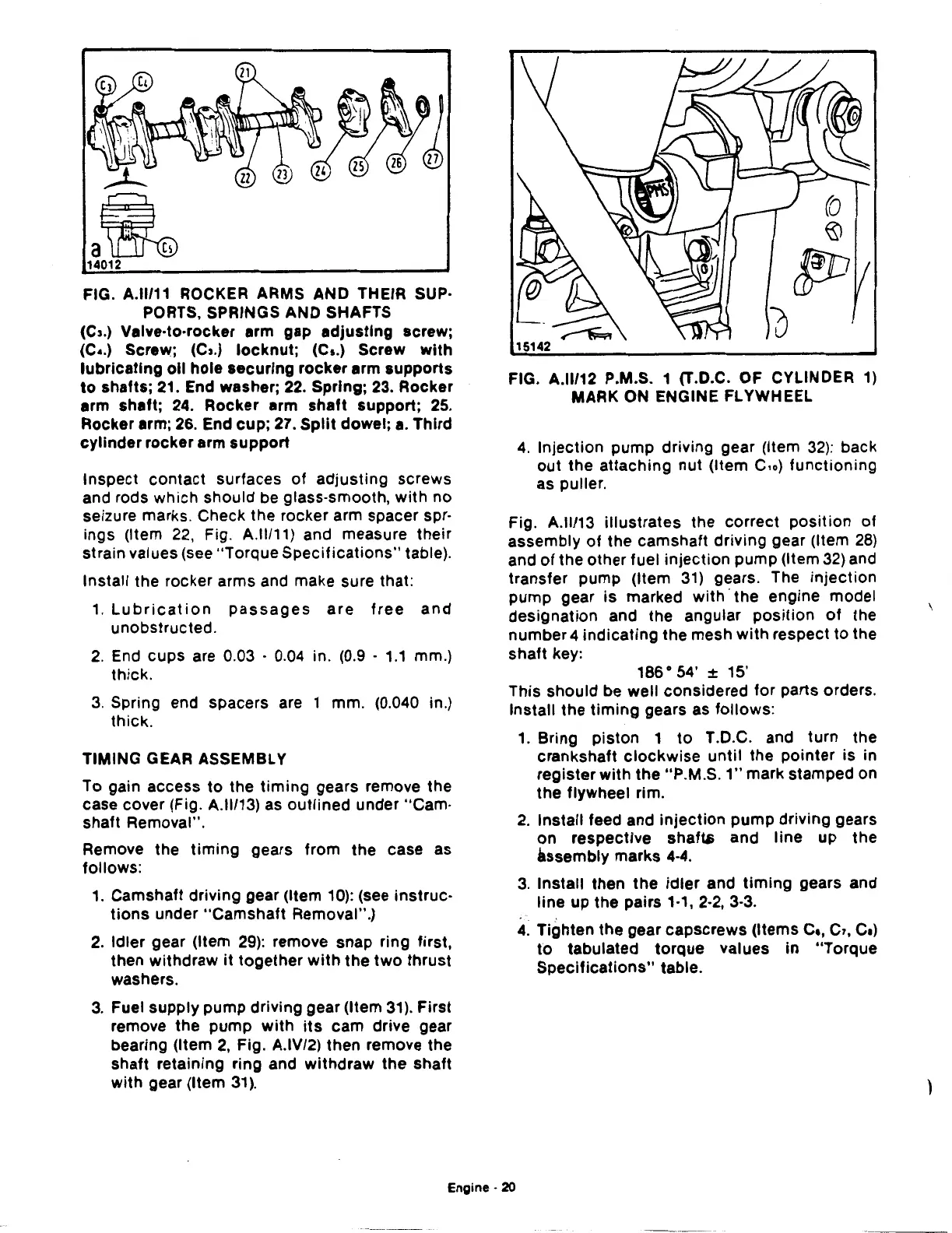

FIG. A.ll/12 P.M.S. 1 (T.D.C. OF CYLINDER

1)

MARK ON ENGINE FLYWHEEL

4.

Injection pump driving gear (Item

32):

back

out

the attaching nut (Item

C.o)

functioning

as puller.

Fig. A.ll/13 illustrates the correct position

of

assembly

of

the camshaft driving gear (Item

28)

and

of

the other fuel injection pump (Item

32)

and

transfer pump (Item

31)

gears. The

injection

pump gear

is

marked

with·

the engine model

designation and the angular

position

of

the

number 4 indicating the mesh

with

respect

to

the

shaft key:

186° 54'

± 15'

This should be well considered for parts orders.

Install the

timing

gears as follows:

1.

Bring piston 1

to

T .D.C. and turn the

crankshaft

clockwise

until the pointer is in

register

with

the "P.M.S.

1"

mark stamped on

the flywheel rim.

2.

Install feed and injection pump driving gears

on

respective

shafw

and line up the

assembly marks

4-4.

3.

Install then

the

idler

and

timing

gears and

line up the pairs 1·1, 2·2, 3-3.

4.

Tighten the gear capscrews (Items

c.,

C1,

Ce)

to

tabulated torque values in "Torque

Specifications"

table.

Engine·

20

\

Loading...

Loading...