REMOVAL

Remove the pump from the

tractor

by removing

the

capscrews which secure it

to

the

engine

tim·

ing gear case cover and the capscrews securing

the

suction

and delivery

oil

lines (Items

21

and

20,

Fig. C.0/3).

Withdraw

it

then at front and recover the align-

ment ring (Item

12,

Fig. C.0/30), the driving ring

(Item

14)

and the gasket inserted between pump

and

timing

gear case cover.

OISASSEMBL Y

Clamp the

pump

in a bench vise provided

with

soft

lead jaws, then disassemble

it

as follows:

1.

Unscrew the nut (Item Cl, Fig. C.0/29) from

the drive shaft, then withdraw the drive

sleeve and retaining ring.

2.

Remove flange and cover and

their

sealing

rings after removing

the

attaching bolts.

3.

Remove gears and bearings, tapping the

shaft ends

with

a plastic mallet. We recom·

mend scribing assembly

of

the parts,

if

still

usable.

4.

Remove from the cover the drive shaft seals

and the spacer, after removing the retaining

ring.

5.

Remove the inner and outer seals from

flange and cover, the latter provided

with

a

plastic back-up ring.

INSPECTION

Following

a thorough cleaning

of

the parts,

but

avoiding solvents which may damage the

oil

seals. proceed as follows:

1.

Check flange and cover seals and the

two

drive shaft seals for scored working surfaces

or

permanent damage, and refit them

if

found

functionally

efficient.

However,

it

is best

to

replace all

of

them at overhauls.

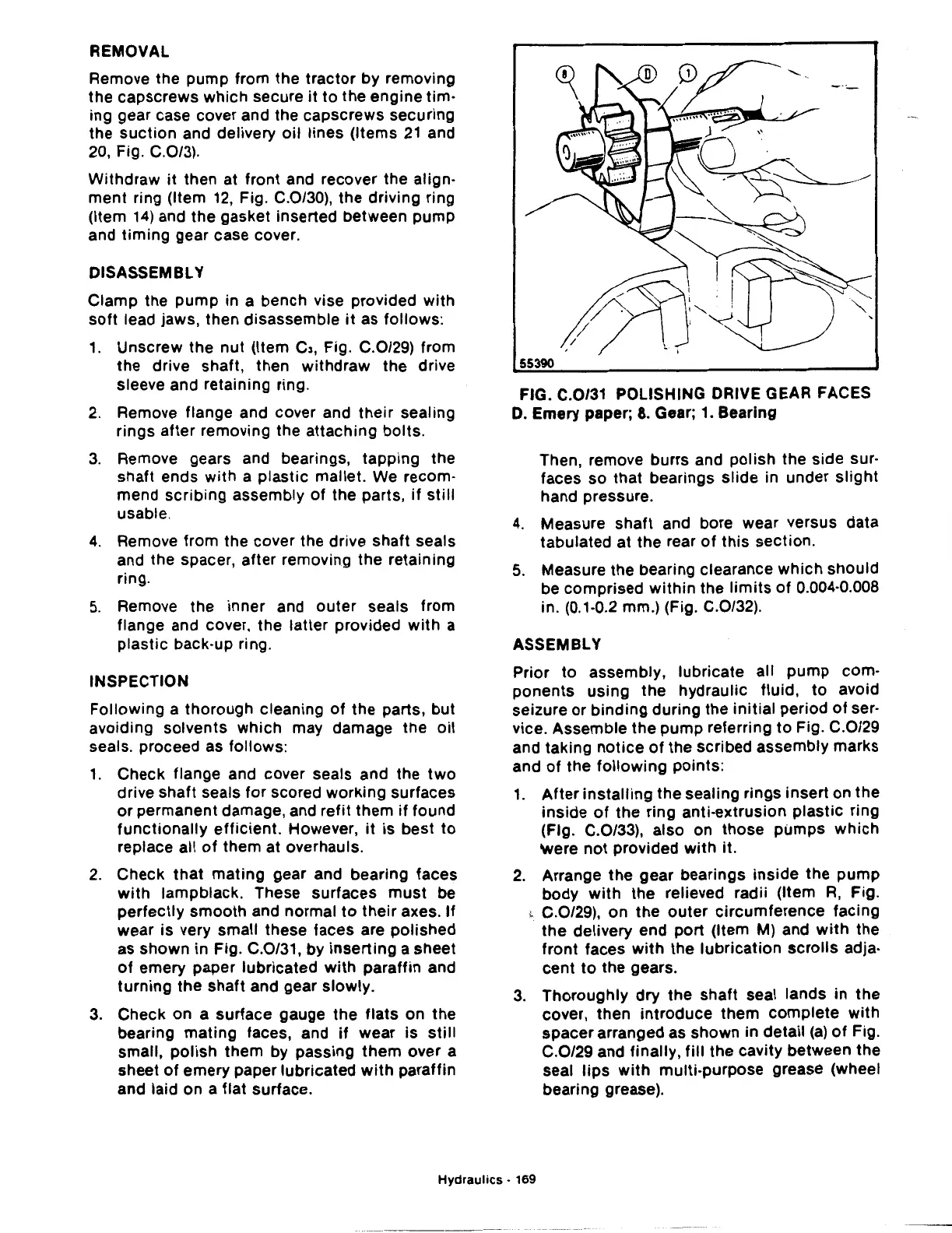

2.

Check

that

mating

gear and bearing faces

with

lampblack. These surfaces

must

be

perfectly smooth and normal

to

their

axes.

If

wear is very small these faces are polished

as shown in Fig. C.0/31, by

inserting

a sheet

of

emery paper lubricated

with

paraffin and

turning

the

shaft and gear slowly.

3.

Check on a surface gauge the

flats

on

the

bearing mating faces, and

if

wear is

still

small,

polish

them by passing

them

over a

sheet

of

emery paper lubricated

with

paraffin

and laid on a flat surface.

FIG. C.0/31 POLISHING DRIVE GEAR FACES

0.

Emery paper; 8. Gear; 1. Bearing

Then, remove burrs and polish the side sur·

faces so that bearings slide in under

slight

hand pressure.

4.

Measure shaft and bore wear versus data

tabulated at the rear

of

this

section.

5.

Measure the bearing clearance which should

be comprised

within

the

limits

of

0.004·0.008

in. (0.1·0.2 mm.) (Fig. C.0/32).

ASSEMBLY

Prior to assembly, lubricate all pump com-

ponents using

the

hydraulic fluid, to avoid

seizure or binding during the

initial

period

of

ser-

vice. Assemble the pump referring

to

Fig. C.0/29

and taking

notice

of

the scribed assembly marks

and

of

the

following

points:

1.

After

installing

the sealing rings insert on

the

inside

of

the ring anti-extrusion

plastic

ring

(Fig. C.0/33), also on those pumps

which

were

not

provided

with

it.

2.

Arrange

the

gear bearings

inside

the

pump

body

with

the relieved radii (Item

R,

Fig.

,.

C.0/29), on

the

outer

circumference facing

the

delivery end port (Item M) and

with

the

front faces

with

the lubrication

scrolls

adja-

cent

to

the gears.

3.

Thoroughly

dry

the shaft seal lands

in

the

cover, then introduce them complete

with

spacer arranged as shown in detail

(a)

of

Fig.

C.0/29 and finally,

fill

the cavity between the

seal

lips

with

multi-purpose grease (wheel

bearing grease).

Hydraulics

• 169

Loading...

Loading...