'

A.l CRANKCASE-CYLINDER HEAD-OIL SUMP

For a general overall inspection

of

the crankcase

components, remove

~ngine

from tractor as in·

dicated on page

6.

CRANKCASE AND CYLINDER LINERS

The cast iron crankcase and cylinder

block

unit

construction

comprises the cylinder liner bores,

crankshaft main bearings, camshaft bearing

bores, and the valve tappet bores. Cylinder

liners,

of

the dry type, are inserted by cold press

fitting.

New liners

must

be bored

to

proper size

after

installation in engine bore. (See

"Fits

and

Tolerances-Torque Specifications-section.)

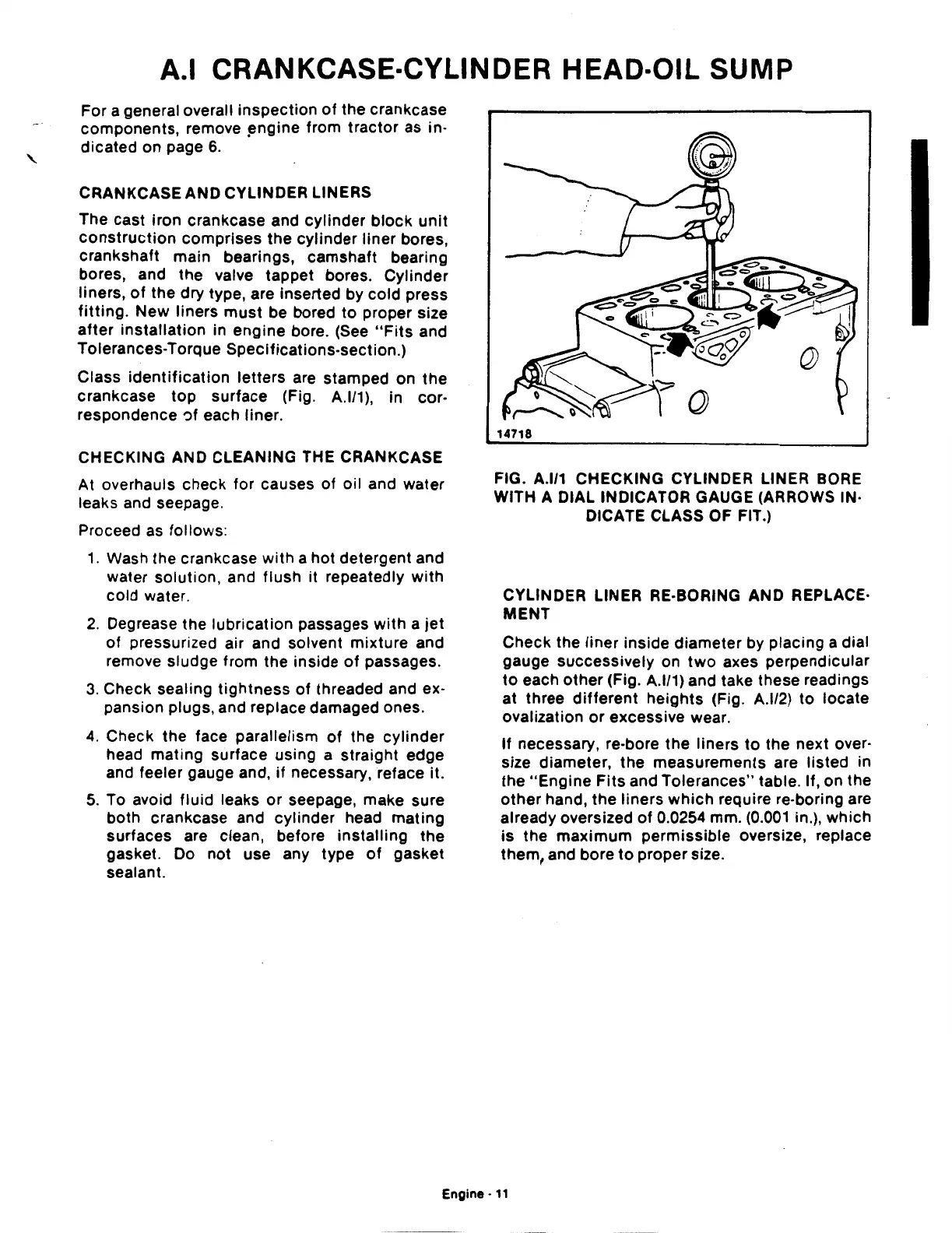

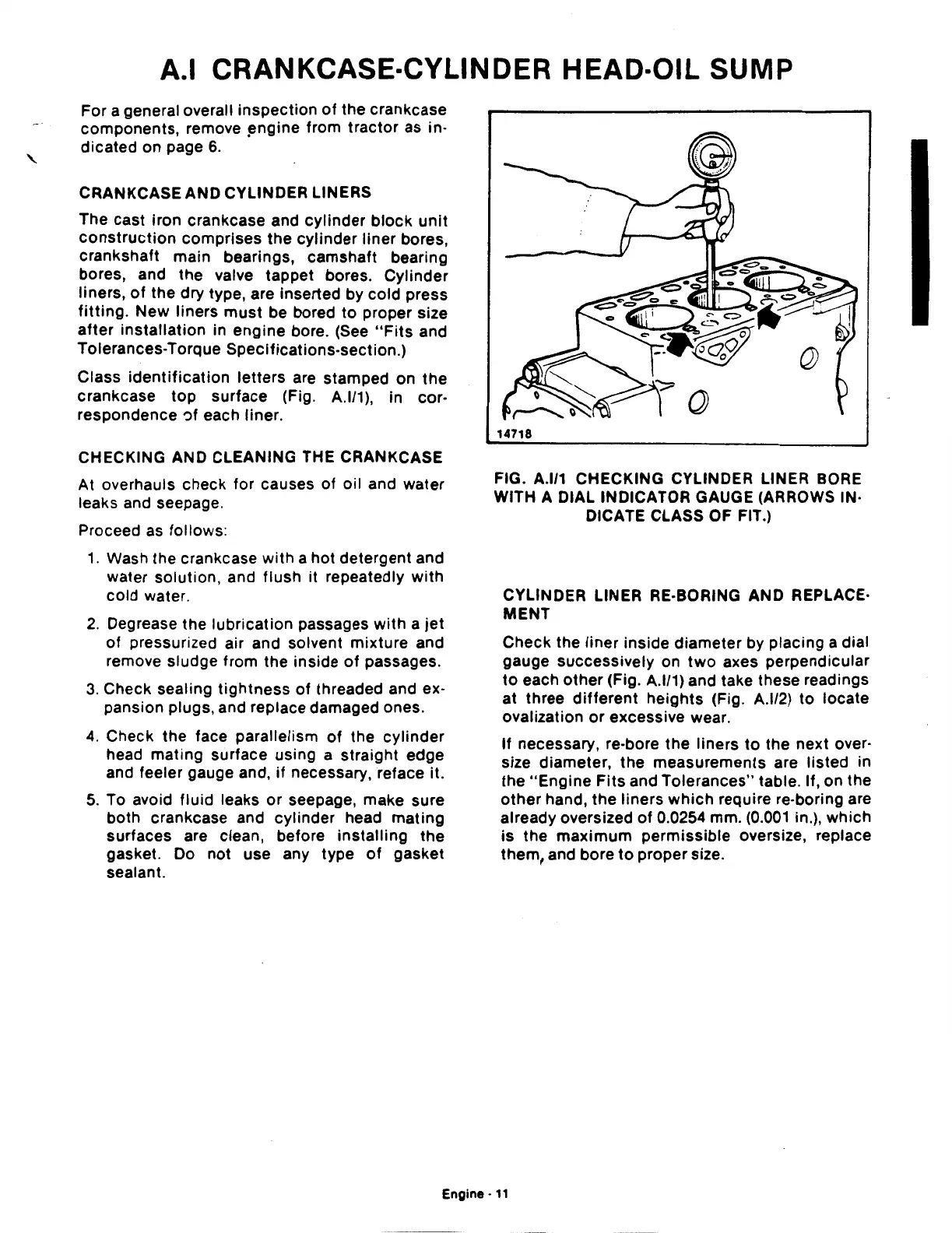

Class

identification

letters

are stamped on

the

crankcase

top

surface (Fig. A.l/1

),

in cor-

respondence ':lf each liner.

CHECKING AND CLEANING THE CRANKCASE

At overhauls check for causes of oil and water

leaks and seepage.

Proceed

as

follows:

1.

Wash the crankcase with a hot detergent and

water solution, and flush it repeatedly

with

cold water.

2.

Degrease the lubrication passages

with

a

jet

of pressurized air and solvent mixture and

remove sludge from the inside

of

passages.

3.

Check sealing

tightness

of

threaded and ex-

pansion plugs, and replace damaged ones.

4.

Check the face parallelism

of

the cylinder

head mating surface using a straight edge

and feeler gauge and,

if

necessary, reface it.

5.

To avoid fluid leaks or seepage, make sure

both crankcase and cylinder head mating

surfaces are clean, before installing the

gasket. Do not use any type

of

gasket

sealant.

14718

FIG. A.l/1 CHECKING CYLINDER LINER BORE

WITH A DIAL INDICATOR GAUGE (ARROWS IN·

DICATE CLASS OF FIT.)

CYLINDER LINER RE-BORING AND REPLACE·

MENT

Check the

liner

inside diameter by placing a dial

gauge successively on

two

axes perpendicular

to

each other (Fig. A.l/1) and take these readings

at three

different

heights (Fig. A.l/2)

to

locate

ovalization

or

excessive wear.

If

necessary, re-bore

the

liners

to

the next over·

size diameter, the measurements are listed in

the

"Engine

Fits

and Tolerances" table. If, on the

other

hand, the liners

which

require re-boring are

already oversized

of

0.0254 mm.

(0.001

in.), which

is

the maximum permissible oversize, replace

them, and bore

to

proper size.

Engine·

11

Loading...

Loading...