withdraw the driven shaft

(40,

Fig.

8.11/28)

and

ball bearing

(41)

rearwards as

an

assembly

acting on the front end

as

illustrated;

recover the gears and the synchromesh

device from the housing;

remove, at the press

if

necessary, the rear

roller bearing

(41)

from the shaft and the front

ball bearing

(43,

Fig~

8.11/30)

from the hous-

ing, the latter with the aid

of

a drive bar.

25027

25026

Jl. /

FIG.

8.11/28

REMOVING THE DRIVEN SHAFT

(40)

41. Rear roller bearing.

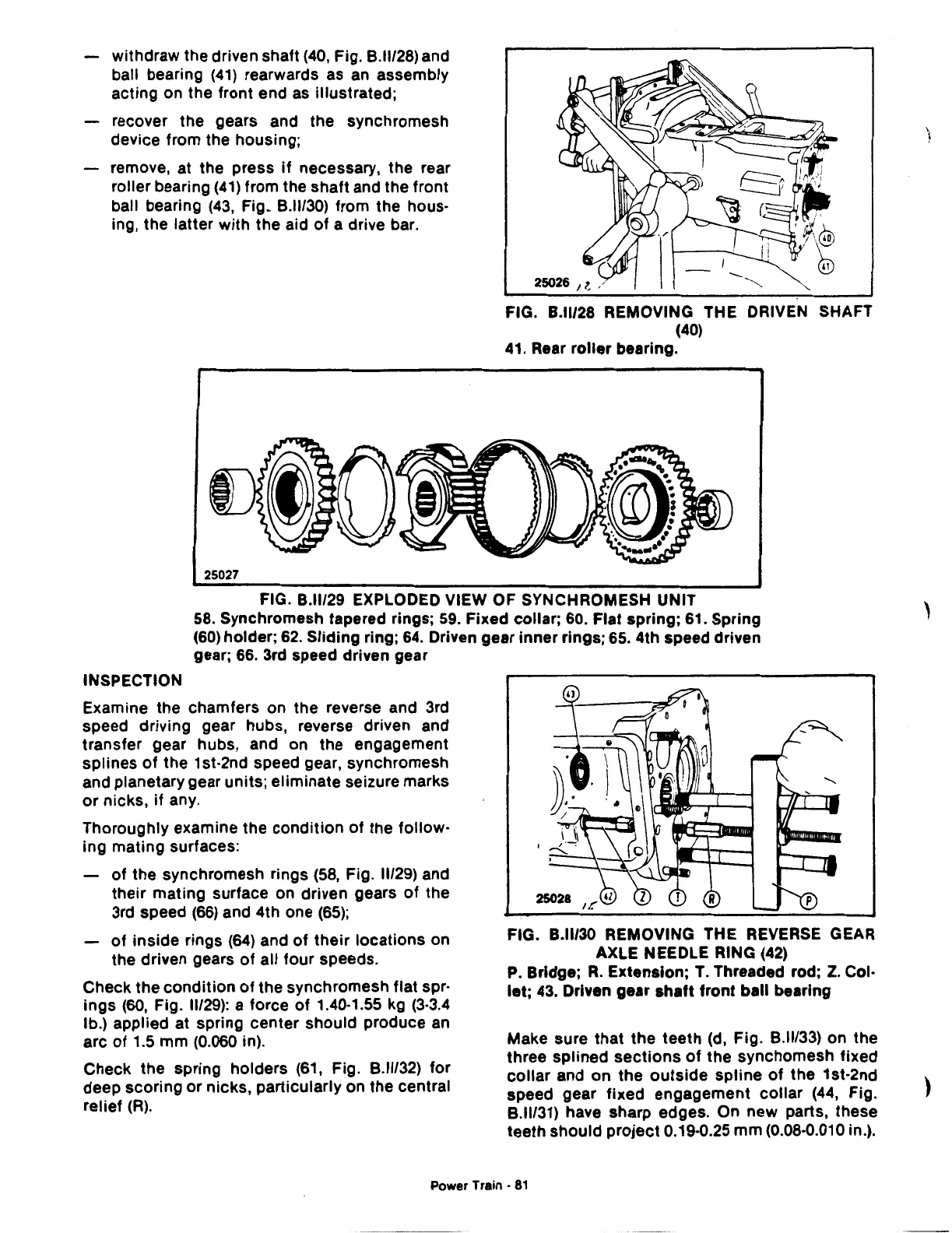

FIG.

8.11/29

EXPLODED VIEW OF SYNCHROMESH UNIT

58.

Synchromesh tapered rings;

59.

Fixed collar;

60.

Flat spring;

61.

Spring

(60)

holder;

62.

Sliding ring;

64.

Driven gear inner rings;

65.

4th speed driven

gear;

66.

3rd speed driven gear

INSPECTION

Examine the chamfers on the reverse and 3rd

speed driving gear hubs, reverse driven and

transfer gear hubs, and on the engagement

splines

of

the 1st-2nd speed gear, synchromesh

and planetary gear units; eliminate seizure marks

or

nicks,

if

any.

Thoroughly examine the condition

of

the follow-

ing mating surfaces:

of

the synchromesh rings

(58,

Fig.

11/29)

and

their mating surface on driven gears

of

the

3rd speed

(66)

and 4th one

(65);

of

inside rings

(64)

and

of

their

locations on

the driven gears

of

all four speeds.

Check the condition

of

the synchromesh flat spr-

ings

(60,

Fig.

11/29):

a force

of

1.40·1.55

kg

(3·3.4

lb.) applied at spring center should produce

an

arc

of

1.5 mm (0.060 in).

Check the spring holders

(61,

Fig.

8.11/32)

for

deep scoring

or

nicks, particularly on the central

relief

(R).

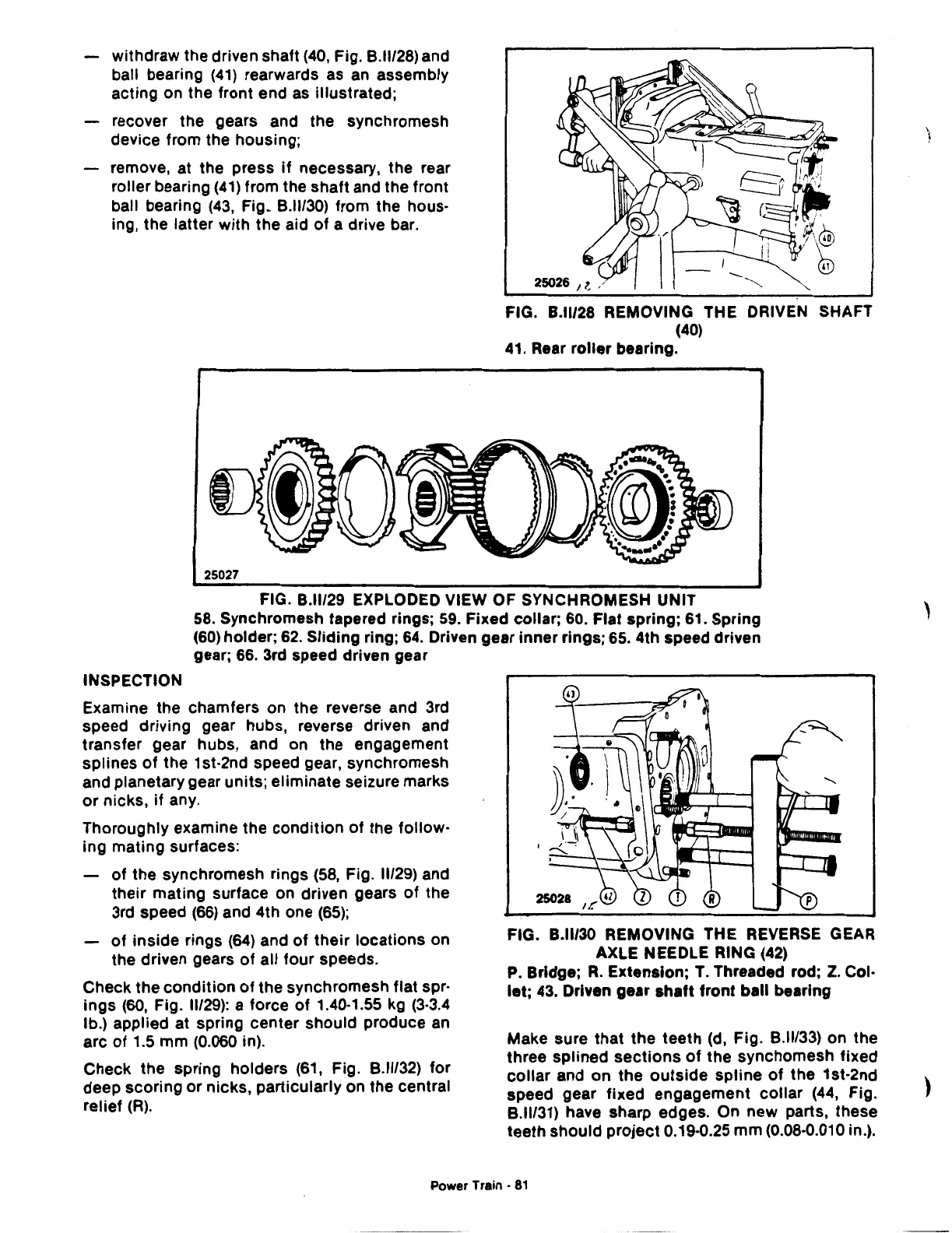

FIG.

8.11/30

REMOVING THE REVERSE GEAR

AXLE NEEDLE RING

(42)

P.

Bridge;

R.

Extension;

T.

Threaded rod;

Z.

Col·

let;

43.

Driven gear shaft front ball bearing

Make sure that the teeth

(d,

Fig.

8.11133)

on the

three splined

sections

of

the synchomesh fixed

collar

and on the

outside

spline

of

the 1st-2nd

speed gear fixed engagement collar

(44,

Fig.

8.11131)

have sharp edges. On new parts, these

teeth should project 0.19·0.25 mm (0.08·0.010 in.).

Power Train •

81

'

)

Loading...

Loading...