10"

CLUTCH ADJUSTMENTS

The data necessary

for

the correct

adjustment

of

the

clutch

are noted by

the

letters

"A"

and

"B"

in

the

legend

of

Fig.

8.116.

The play A is set

with

the

clutch

installed on the

stand,

while

the play

B,

between the disengaging

sleeve

(12)

and levers

(11

),

is

featured by ad·

justing

the

free travel

of

the

control

pedal.

The

adjustments

made

with

the

clutch

installed

on the stand are, as

follows:

1.

To

adjust

the play (Item

A,

Fig.

8.116)

of

the

P.T.O.

clutch

release levers (Item

13),

install

the

clutch

without

the P.T.O.

clutch

disc

on

the universal stand (Item

0,

Fig.

8),

after

assembling

the spacer

bushings

(Item H) in

their

holes.

Insert the

clutch

centering

shaft

(Item

F),

6

speed

clutch

tool,

part no. 754246.

Secure the

clutch

to

the universal stand by

using the 3 threaded rods (Item

G,

Fig.

8.1/7)

which

are

tightened

up on the same line

with

the

outer

spacer bushings.

Loosen the three

nuts

(Item

A2,

Fig.

8.1/6)

and

screw in the adjustinQ screws (Item

A.,)

until

a play

of

0.030" (0.75 mm.) is

obtained

(measured

with

a feeler gauge), then

tighten

the

lockrwts

(Item

A2).

This

adjustment

is

also carried

out

or checked on the

tractor

through

the

inspection

cover

window

on the

right hand side

of

the

transmission

housing

(Fig.

8.118).

To bring the screws (Item A,) in

line

with

the window,

shift

the

transmission

in neutral and rotate the

crankshafrto

suit.

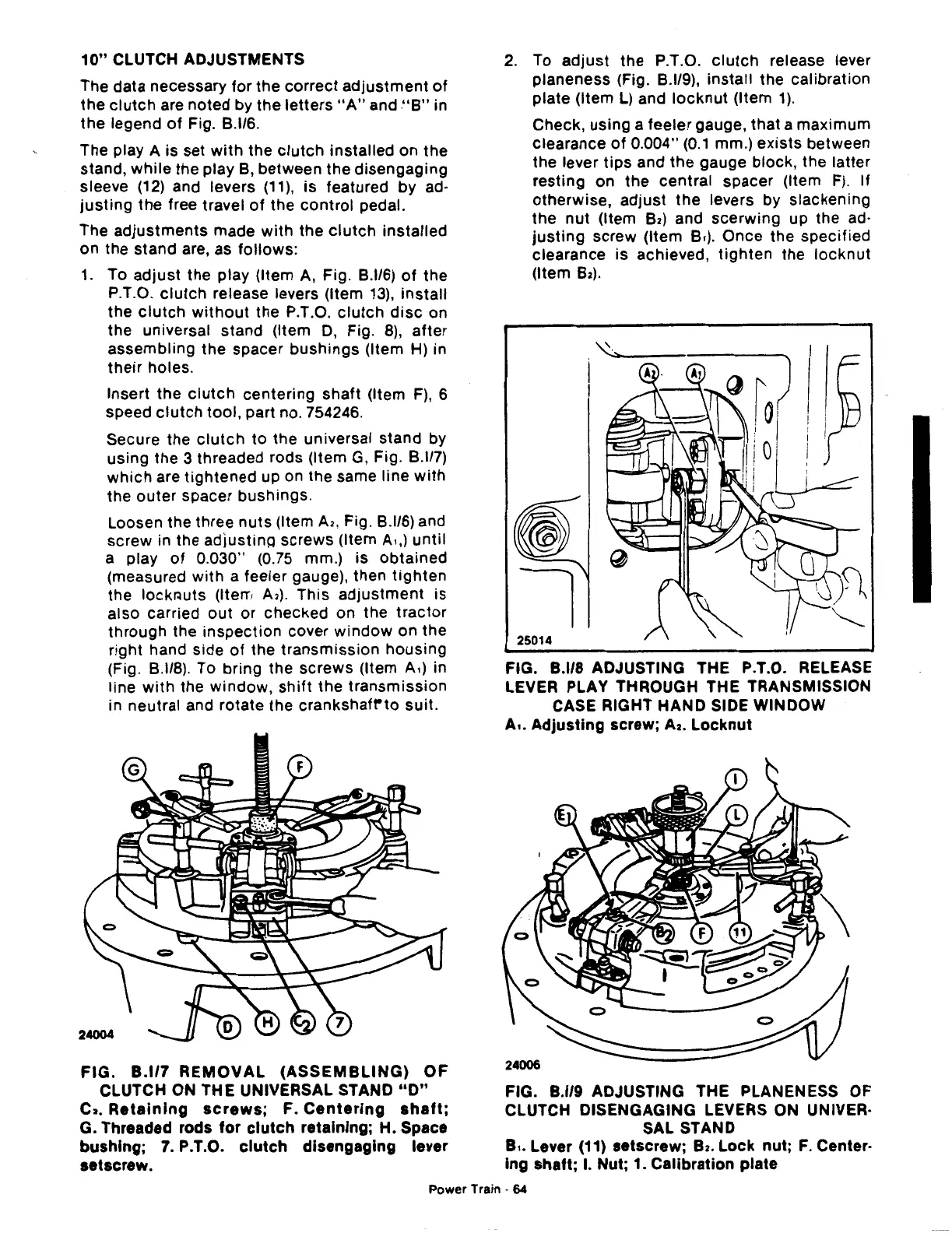

FIG.

8.117

REMOVAL

(ASSEMBLING)

OF

CLUTCH ON THE UNIVERSAL STAND

"D"

C2.

Retaining

screws;

F.

Centering

shaft;

G. Threaded rods

for

clutch

retaining; H. Space

bushing;

7.

P.T.O.

clutch

disengaging lever

setscrew.

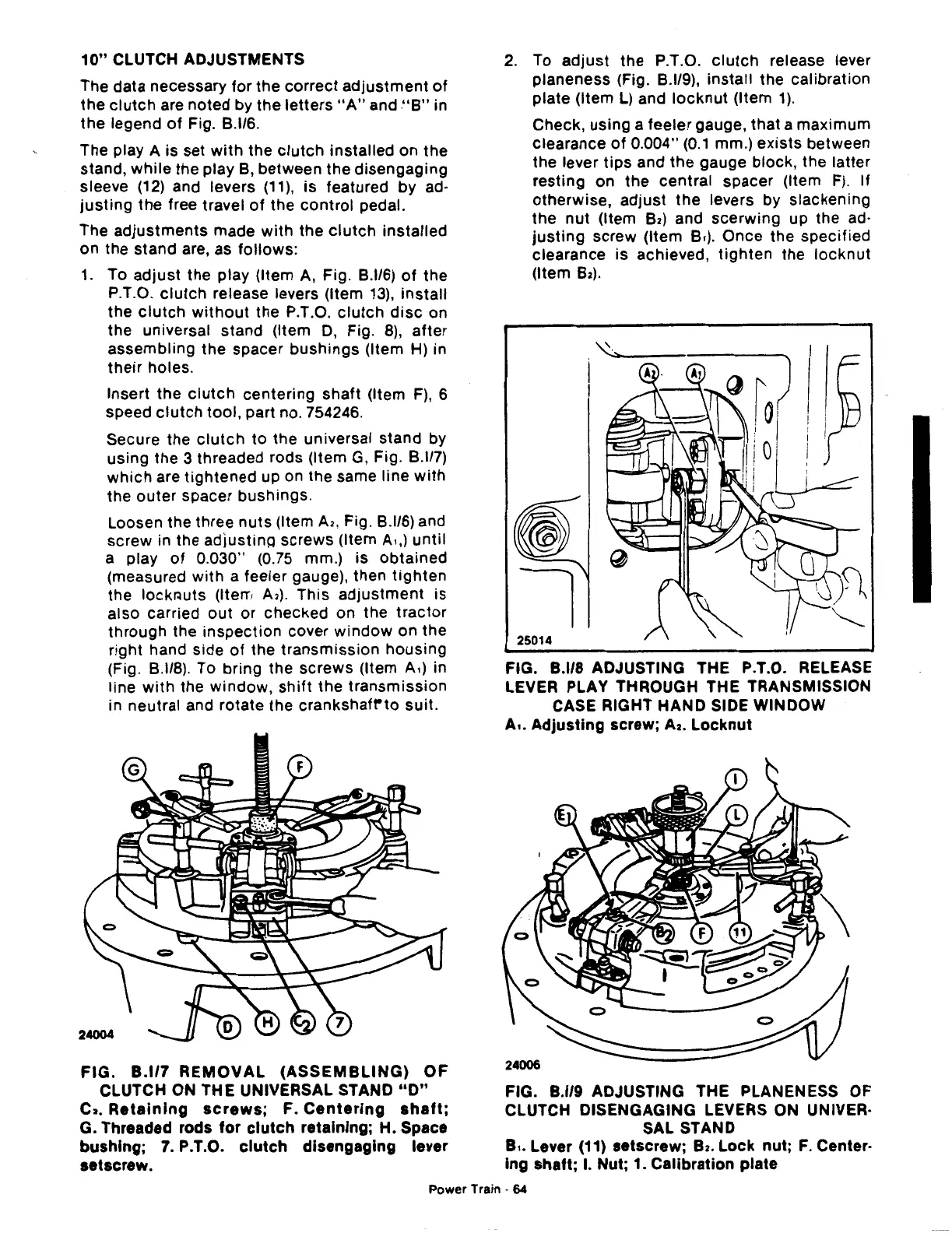

2.

To

adjust

the P.T.O.

clutch

release lever

planeness (Fig.

8.1/9),

install the calibration

plate (Item

L)

and

locknut

(Item

1).

Check, using a feeler gauge, that a maximum

clearance

of

0.004"

(0.1

mm.)

exists

between

the lever

tips

and the gauge block, the latter

resting on the central spacer (Item

F).

If

otherwise,

adjust

the

levers by slackening

the

nut

(Item

Bz)

and

scerwing

up the ad·

justing

screw (Item B.). Once the

specified

clearance is achieved,

tighten

the

locknut

(Item

Bz).

"

....

I

25014

FIG. 8.1/8 ADJUSTING THE P.T.O. RELEASE

LEVER PLAY THROUGH THE TRANSMISSION

CASE RIGHT

HAND

SIDE WINDOW

A,.

Adjusting

screw;

A2.

Locknut

FIG. 8.1/9 ADJUSTING THE PLANENESS OF

CLUTCH DISENGAGING LEVERS ON UNIVER·

SAL STAND

8,.

Lever (11) setscrew; 82.

Lock

nut;

F.

Center·

lng

shaft; I. Nut; 1. Calibration plate

Power Train ·

64

Loading...

Loading...