BEVEL GEAR SETTING

Adjustment

operations are grouped under the

following

subtitles:

1.

Adjusting

the

bevel gear

pinion

shaft tapered

roller

bearings and

finding

shim

thickness

(Item Sp, Fig.

8.11116).

Install

the

pinion

shaft

with

a

stack

of

shims

(Item

s,,

Fig.

8.11118)

of

any thickness, the

tapered roller bearings (Items

21

and 24)

previously lubricated, the P.T.O. driving gear

(Item

22) and

its

spacer (Item 23), then make

sure that the gear, the rear bearing cone, the

shim

and the

pinion

back end are all in con-

tact

with

each other.

Lubricate the

locknut

(Item

C3)

thread

with

crankcase oil and gradually

tighten

it

with

the

torque wrench F (Fig.

8.11119)

with

torque

increments

of

1.5 ft.-lbs.

(2

N•m)

up

to

the

value

of

7.2

ft.-lbs.

(10

N•m). Simultaneously,

turn the shaft a few turns

after

each torquing

step

to

make sure the tapered rollers are pro-

perly seated.

NOTE:

After

turning the shaft

following

the

final torquing step, re-check the torque and

reset

it

if

necessary.

Measure the clearance (Item L,, Fig.

8.111/8)

with

a feel gauge between P.T.O. driving gear

and spacer and select

two

adjustment

shims

(Item Sp, Fig.

8.11116)

the sum

of

which

is

equal to the value

of

the clearance previously

measured plus 0.002" (0.05 mm.).

NOTE: When selecting the

shims

(Item Sp),

measure each shim

with

a

micrometer

then

add the readings. Do not rely on a single

measurement

of

the stack

or

on the nominal

thickness

given for the individual shims.

2.

Checking the pinion cone center distance

and

finding

the correct

thickness

of

the shim

pack (Item

S,

Fig.

8.111/6).

Remove the bevel gear

pinion

shaft previous-

ly installed, install the reference shaft (Item

E,

Fig.

8.111/10),

insert the adjustments

shims

(Item Sp) found in paragraph 1 and then

block

the

stack by means

of

the knurled knob.

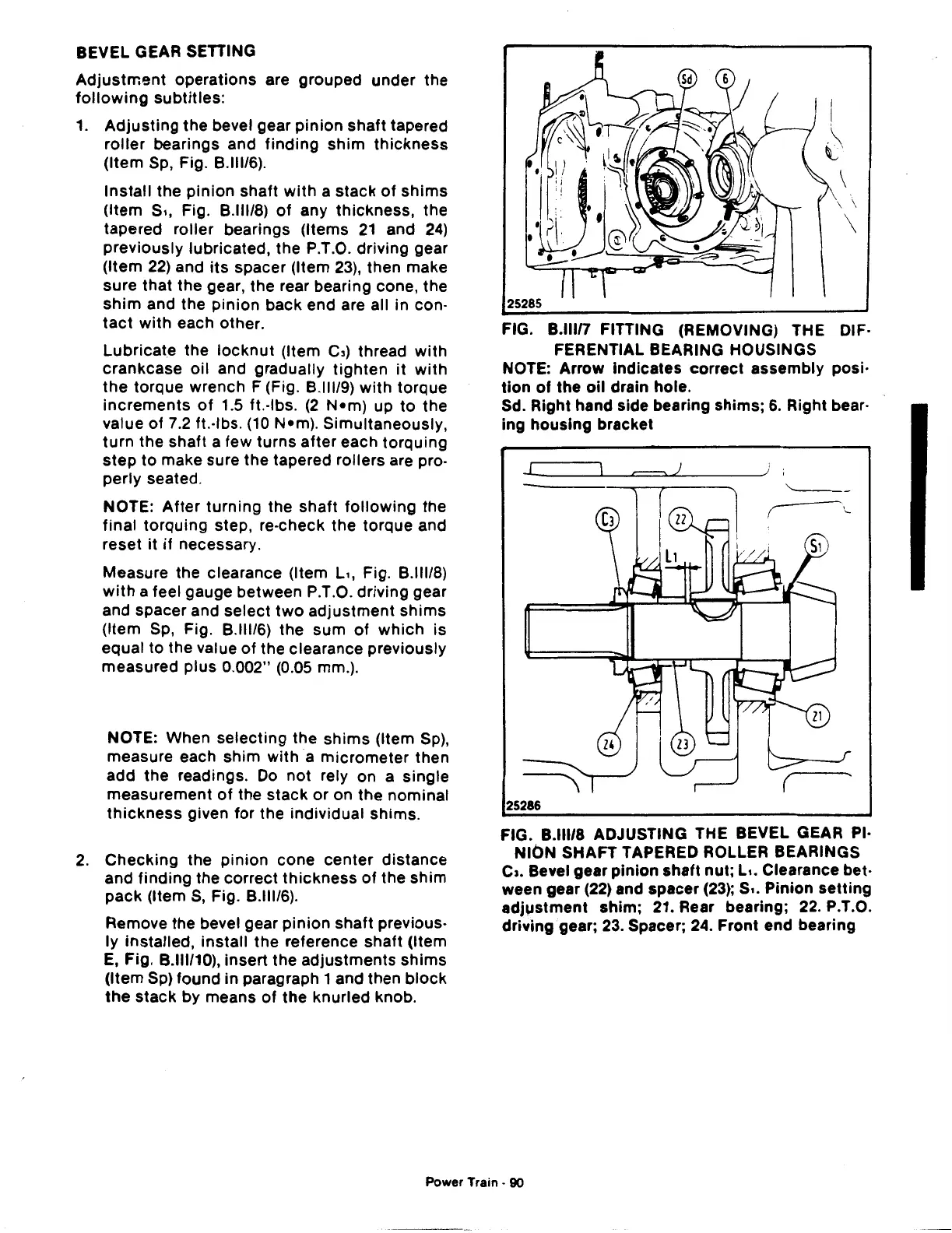

FIG.

B.llln

FITTING (REMOVING) THE DIF-

FERENTIAL BEARING HOUSINGS

NOTE: Arrow Indicates correct assembly posi·

tion

of

the

oil

drain hole.

Sd. Right hand side bearing shims;

6.

Right bear·

ing

housing bracket

~-------~~r==~~J~------~)

;

25286

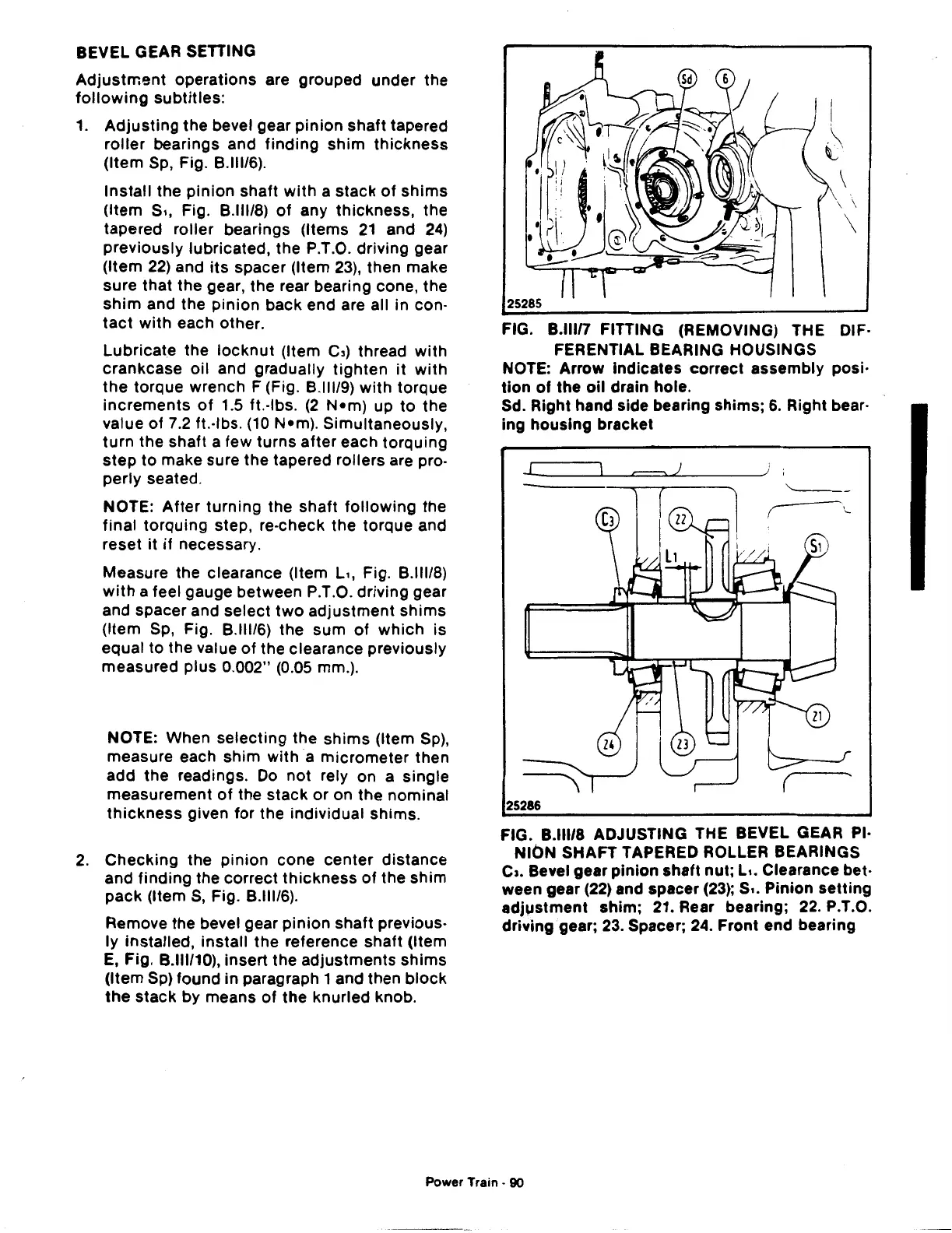

FIG. B.lll/8 ADJUSTING THE BEVEL GEAR PI·

NION SHAFT TAPERED ROLLER BEARINGS

c,.

Bevel gear pinion

shaft

nut; L

••

Clearance bet-

ween gear

(22) and spacer (23); s

..

Pinion setting

adjustment shim; 21. Rear bearing;

22.

P.T.O.

driving gear;

23. Spacer; 24. Front end bearing

Power Train -

90

Loading...

Loading...