Remove the

nut

shaft

complete

and in-

spect the

nut

examining

the

uniformity

of

the

contact

areas on the working surfaces.

To correct,

if

necessary,

suitably

vary

the

shim

stack

(Items,,

Fig. B.VIII/4)

considering

that

if

the stack

is

increased then the

shims

(Item

S),

found in paragraph 1

should

be cor-

respondingly increased and vice-versa.

NOTE: The aforementioned

adjustment

may

be used at steering box overhauls as a fur-

ther

check

of

the worm-and-nut setting,

if

the

parts are reusable. In

this

case we suggest

maintaining the original factory

shim

stack

(Item

s,,

Fig. B.VIII/4).

Alter

the shim

stack

only when one or more parts are replaced.

FRON.T

AXLE AND STEERING

DESCRIPTION

The front axle is

tubular

and

centrally

pivoted

and has

telescopic

beam

extensions

which

allow

a range

of

tread

width

adjustments.

By

moving the front axle beam

extensions

it is

possible

to

obtain the

following

different

tread

width

adjustments:

360C-40-52

in. (1016-1321 mm) 4

positions

360-50.77.5

in. (1280-1975 mm) 8

positions

460V-32.2-41.2 in. (843.3-1153.2 mm) 4

positions

460-50.3-77.5

in. (1280-1975 mm) 8

positions

510-50.3·77.5

in. (1280-1975 mm) 8

positions

OVERHAUL

If the front axle

trunnion

assembly requires ser-

vicing, proceed as

follows:

1.

Apply the hand brake and insert wooden

wedges

to

block

the drive wheels.

2.

At one axle end, remove

the

bolt

(Item c.,

Fig. B.VIII/7), the steering lever (Item

17)

from

the wheel spindle,

withdraw

the

pin (Item

18)

and loosen the

screws

(Item

Ca).

3.

Place a hydraulic

jack

under

the crankcase

oil

sump

and raise

the

front

end

of

the

tractor

to

take the

weight

off

the axle.

4.

Remove the

front

wheel, spindle-beam exten-

sion assembly (Item 19, Fig. B.VIII/7).

5.

Remove the

setscrew

(Item

C1,

Fig. B.VIII/8)

and

then

the

trunnion

pin (Item

20)

using

a

sliding

weight

type

puller

and adaptor.

6. Remove the front axle and

remaining

wheel

as an assembly and recover the end

thrust

washers (Item 25, Fig. B.VIII/9).

---

'85306

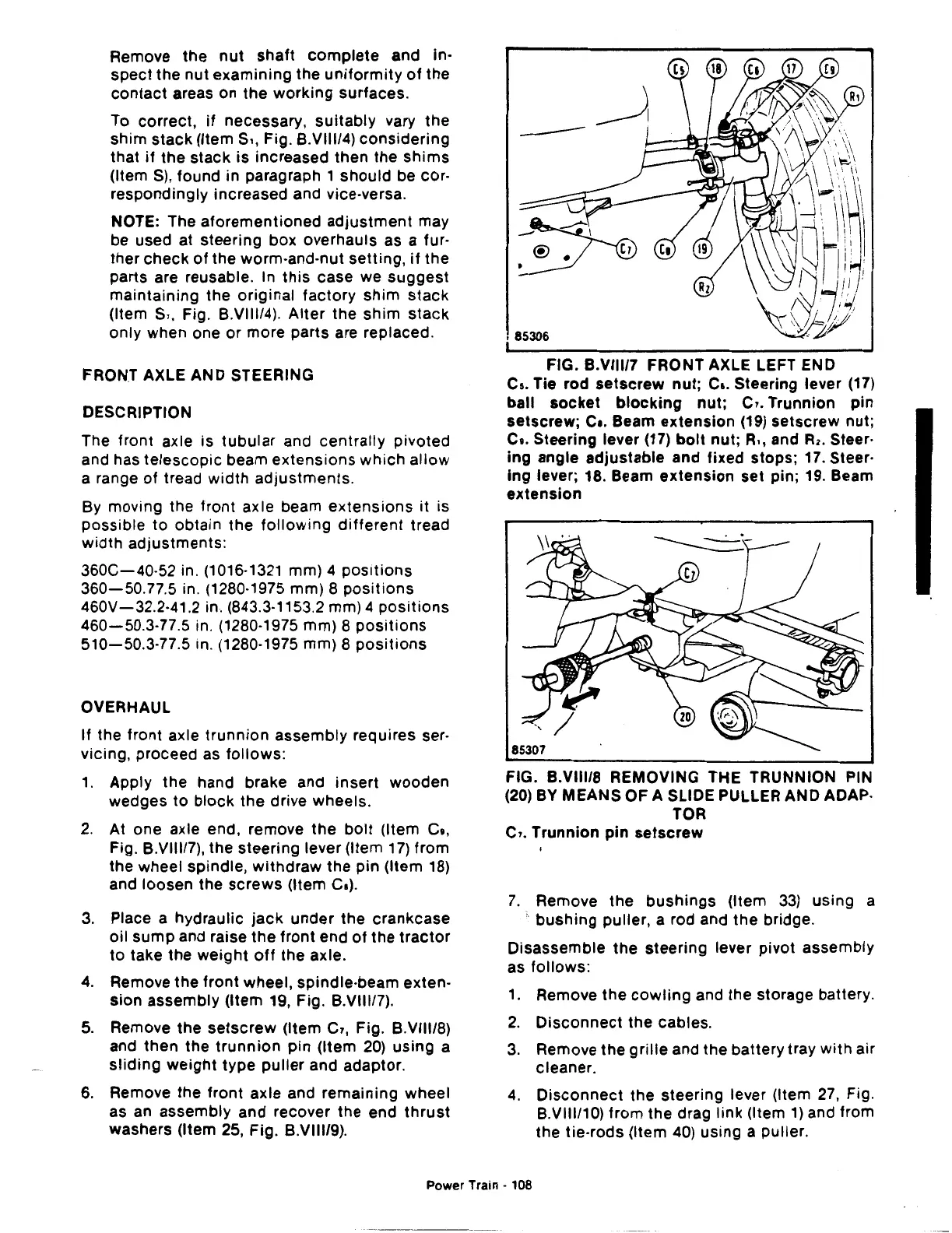

FIG. B.VIII/7 FRONT AXLE LEFT END

Cs.

Tie rod

setscrew

nut;

c

•.

Steering lever

(17)

ball

socket

blocking

nut;

c,. Trunnion pin

setscrew;

c

•.

Beam

extension

(19)

setscrew nut;

c

•.

Steering lever

(17)

bolt

nut; R,, and

R2.

Steer·

ing

angle adjustable and fixed stops; 17. Steer·

ing

lever; 18. Beam

extension

set pin; 19. Beam

extension

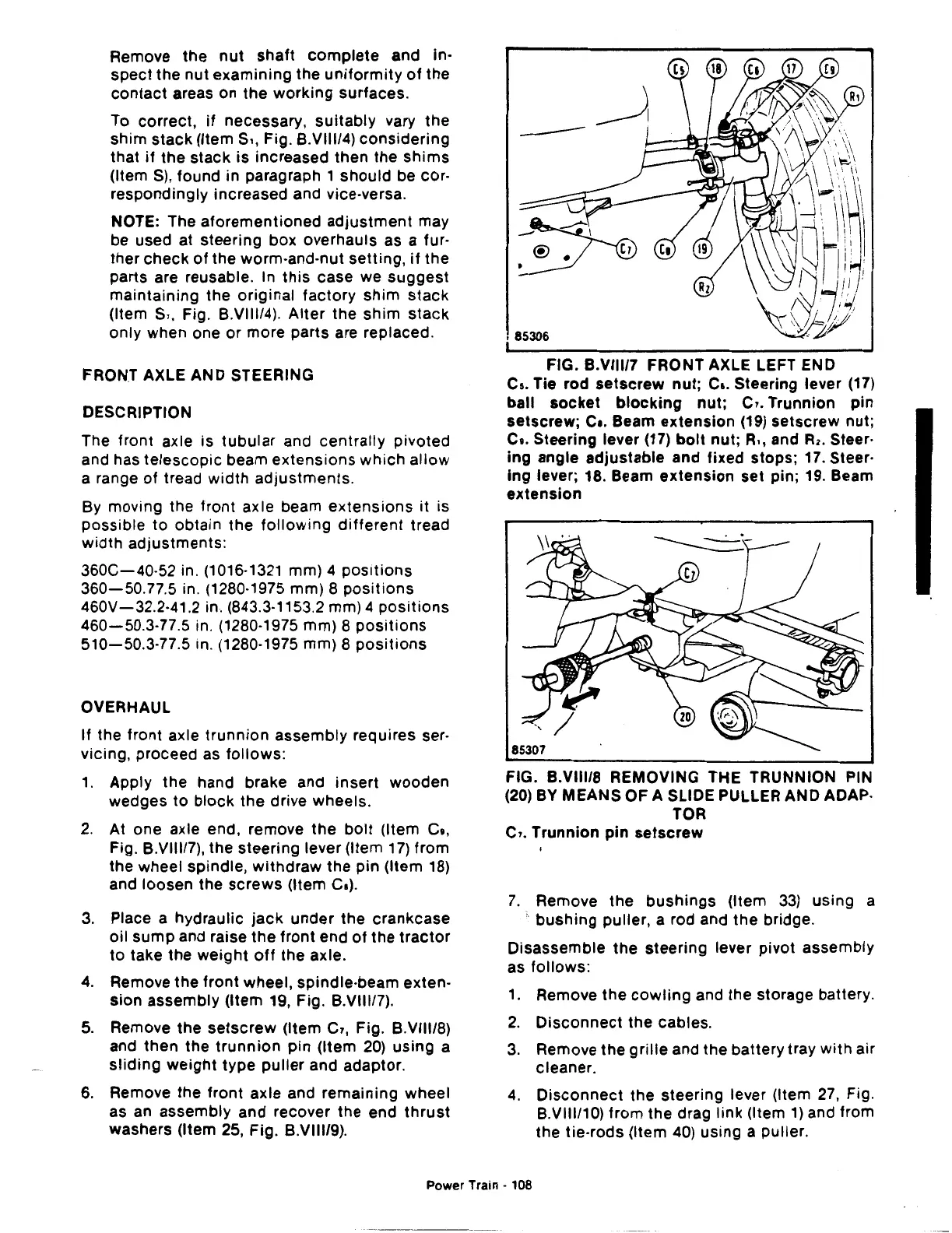

FIG. B.VIII/8 REMOVING THE TRUNNION PIN

(20)

BY

MEANS OF A SLIDE PULLER AND ADAP·

TOR

c,. Trunnion pin

setscrew

7.

Remove the

bushings

(Item

33)

using a

·.

bushing

puller, a rod and the bridge.

Disassemble the

steering

lever pivot assembly

as

follows:

1.

Remove

the

cowling

and the storage battery.

2.

Disconnect

the cables.

3.

Remove the

grille

and the battery tray

with

air

cleaner.

4.

Disconnect

the steering lever (Item

27,

Fig.

B.VIII/10)

from the drag link (Item

1)

and from

the tie-rods (Item

40)

using a puller.

Power Train · 108

Loading...

Loading...