12.

Drain

the

lubricating

oil

from

the

differential

casing.

13.

Screw back the self-locking screws

(57)

and

remove the spherical bracket flange from the

differential

casing, recovering the steering

clamp

(Item

58,

Fig. B.IX/16) and

0-ring

bet-

ween the

two

flanges by

dismantling

the

spherical bracket (Item

26,

B.IX/10)

together

with

the

bushing

(25),

the oil ring

(24)

and the

bearing

outer

races

(27).

The tapered

roller

bearing

outer

races

of

the

joint

casing

should

be removed by the puller. When

necessary

to

replace the

bushing

(25)

and the oil

ring

(24)

use special tools.

14.

complete

removal

of

the

differential

drive pi-

nion (Item

P,

Fig. B.IX/12) from the differen-

tial

casing

is

carried

out

by

screwing

back

the

self-locking

screws (Item 55, Fig. B.IX/11)

and

dismantling

its

components

after

taking

out

the screws.

Be

careful when

withdrawing

the

oil

ring

(48)

the

screwdiver

to

be supported on the

outer

race, so

as

not

to

damage the sealing inner surface.

15.

the

two

outer

races

of

the tapered

roller

bear-

ing

(49

and

51)

and the inner race can be

removed from the support

(43)

and from the

differential

drive shaft

(45)

using

the univer-

sal puller.

16. by

withdrawing

the

right

joint

axis (Item

55,

Fig. B.IX/11) and

left

joint

axis

(17),

by screw-

ing

back the self-locking screws

(53),

the dif-

ferential

casing

should be

complete

separate

from

the

front

drive axle assembly. Recover

0-rings

(29 and

42).

17.

remove

the

differential

casing by

screwing

back the

screws

(54).

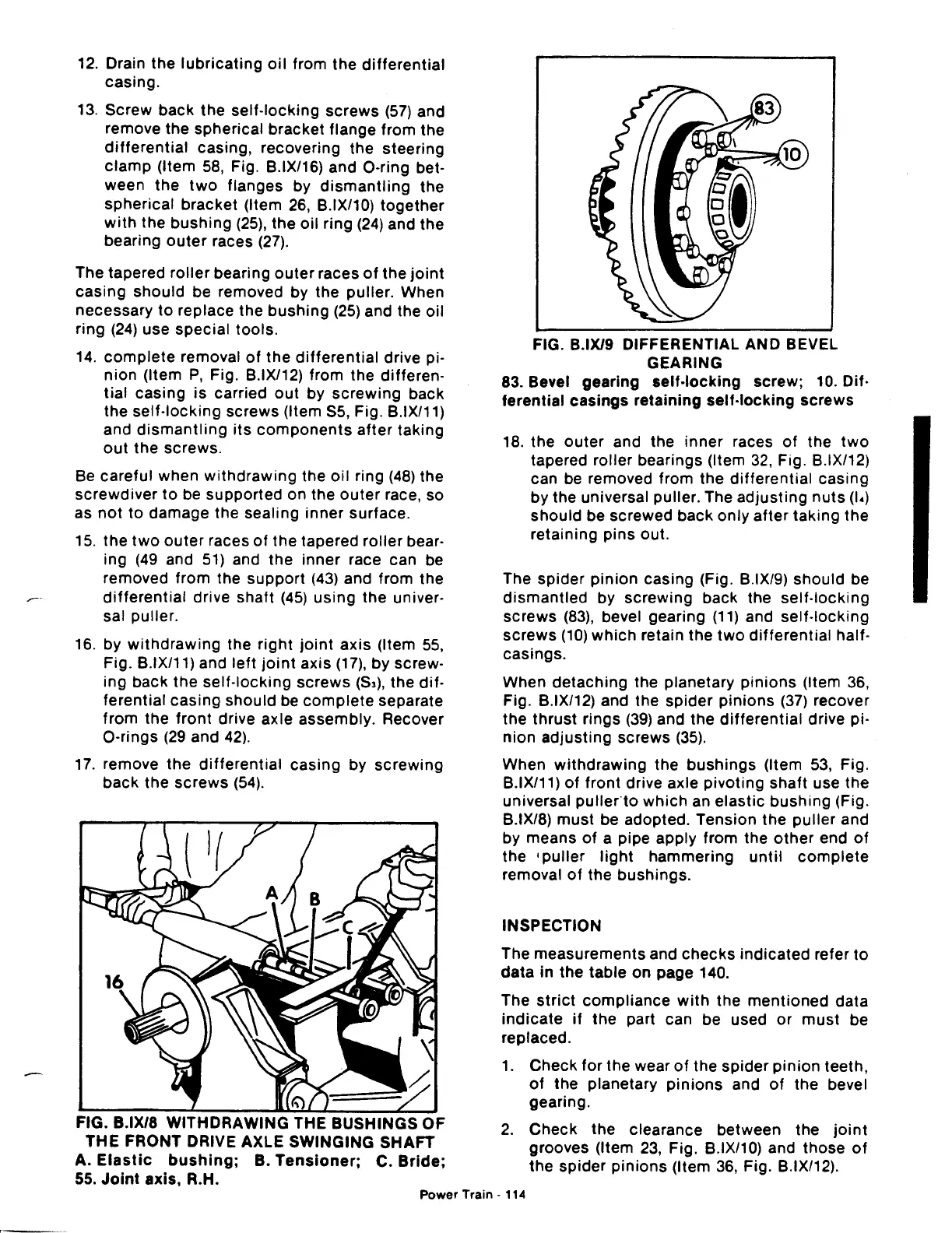

FIG. B.IX/8 WITHDRAWING THE BUSHINGS OF

THE

FRONT DRIVE AXLE SWINGING

SHAFT

A.

Elastic

bushing;

B.

Tensioner;

C.

Bride;

55.

Joint

axis, R.H.

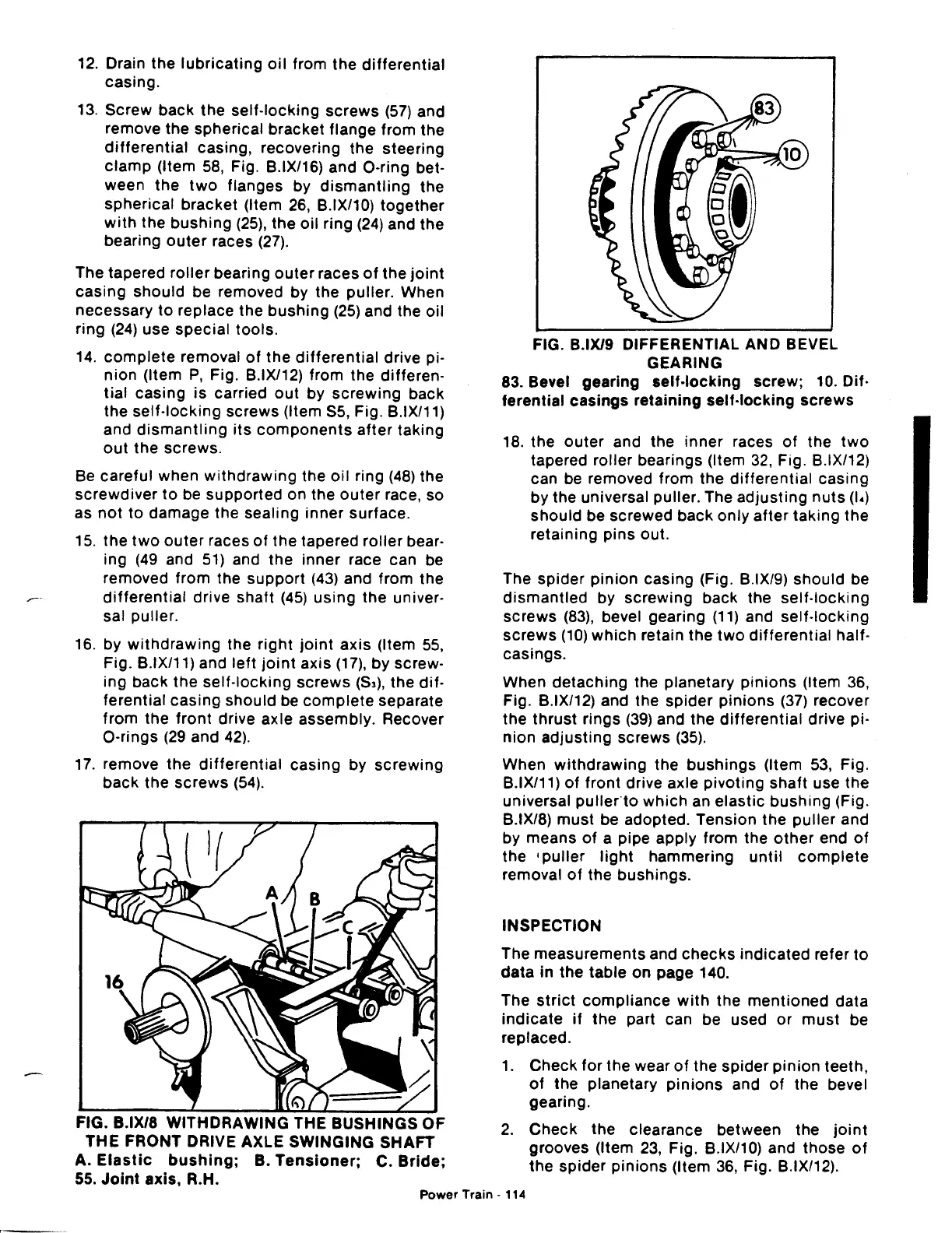

FIG. B.IX/9 DIFFERENTIAL AND BEVEL

GEARING

83. Bevel gearing

self-locking

screw; 10. Dif·

ferential

casings

retaining self-locking screws

18. the

outer

and the inner races

of

the

two

tapered roller bearings (Item

32,

Fig. B.IX/12)

can be removed from the

differential

casing

by the universal puller. The adjusting

nuts

(I•)

should

be screwed back only

after

taking

the

retaining pins out.

The spider

pinion

casing (Fig. B.IX/9) should be

dismantled

by

screwing

back the

self-locking

screws

(83),

bevel gearing

(11)

and self-locking

screws

(10)

which

retain the

two

differential

half-

casings.

When detaching the planetary

pinions

(Item 36,

Fig. B.IX/12) and the spider

pinions

(37)

recover

the

thrust

rings

(39)

and the

differential

drive pi-

nion adjusting screws

(35).

When

withdrawing

the

bushings

(Item

53,

Fig.

B.IX/11)

of

front

drive axle pivoting shaft use the

universal

pulleno

which

an elastic

bushing

(Fig.

B.IX/8)

must

be adopted. Tension the

puller

and

by means

of

a pipe apply from the

other

end

of

the •

puller

light

hammering

until

complete

removal

of

the bushings.

INSPECTION

The measurements and

checks

indicated refer

to

data

in

the

table on page 140.

The

strict

compliance

with

the

mentioned

data

indicate

if

the part can be used

or

must

be

replaced.

1.

Check

for

the wear

of

the spider

pinion

teeth,

of

the planetary

pinions

and

of

the bevel

gearing.

2.

Check the clearance between the

joint

grooves (Item

23,

Fig. B.IX/10) and those

of

the spider

pinions

(Item

36,

Fig. B.IX/12).

Power

Train·

114

Loading...

Loading...