25023

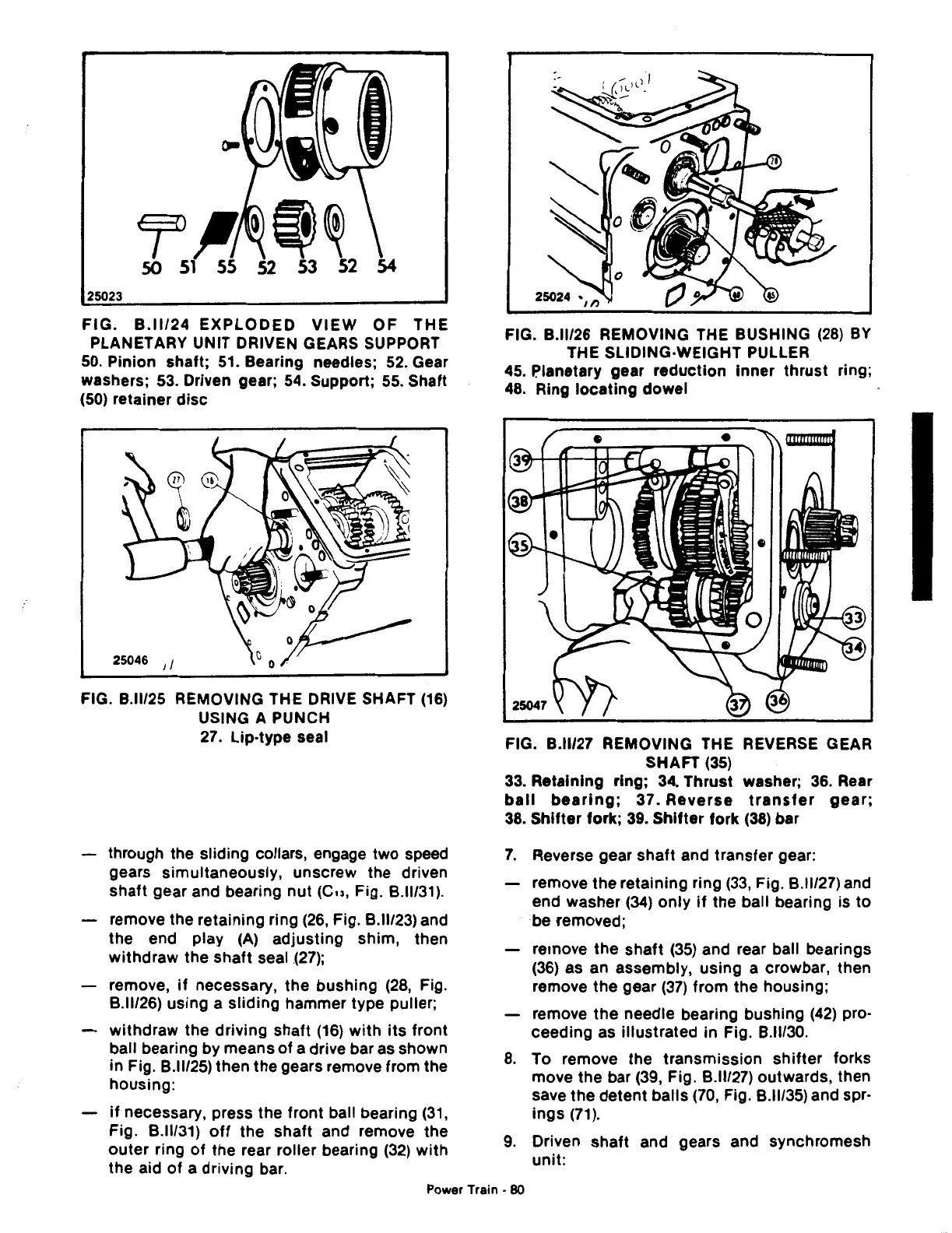

FIG.

B.ll/24

EXPLODED

VIEW

OF

THE

PLANETARY UNIT DRIVEN GEARS SUPPORT

50.

Pinion shaft;

51.

Bearing needles;

52.

Gear

washers;

53.

Driven gear;

54.

Support;

55.

Shaft

(50)

retainer

disc

25046 Jl

FIG. B.lll25 REMOVING THE DRIVE SHAFT

(16)

USING A PUNCH

27.

Lip-type seal

through the sliding collars, engage two speed

gears simultaneously, unscrew the driven

shaft gear and bearing nut (Cu, Fig.

8.11/31).

remove the retaining ring

(26,

Fig.

8.11123)

and

the end play

(A)

adjusting shim, then

withdraw the shaft seal

(27);

remove,

if

necessary, the bushing

(28,

Fig.

8.11126)

using a

sliding

hammer type puller;

withdraw the driving shaft

(16)

with

its

front

ball bearing by means

of

a drive bar as shown

in Fig.

8.11125)

then the gears remove from the

housing:

if

necessary, press the front ball bearing

(31,

Fig.

8.11131)

off

the shaft and remove the

outer

ring

of

the rear roller bearing

(32)

with

the aid

of

a driving bar.

FIG. B.lll26 REMOVING THE BUSHING

(28)

BY

THE SLIDING-WEIGHT PULLER

45. P.lanetary gear reduction inner thrust ring;

48.

Ring

locating

dowel

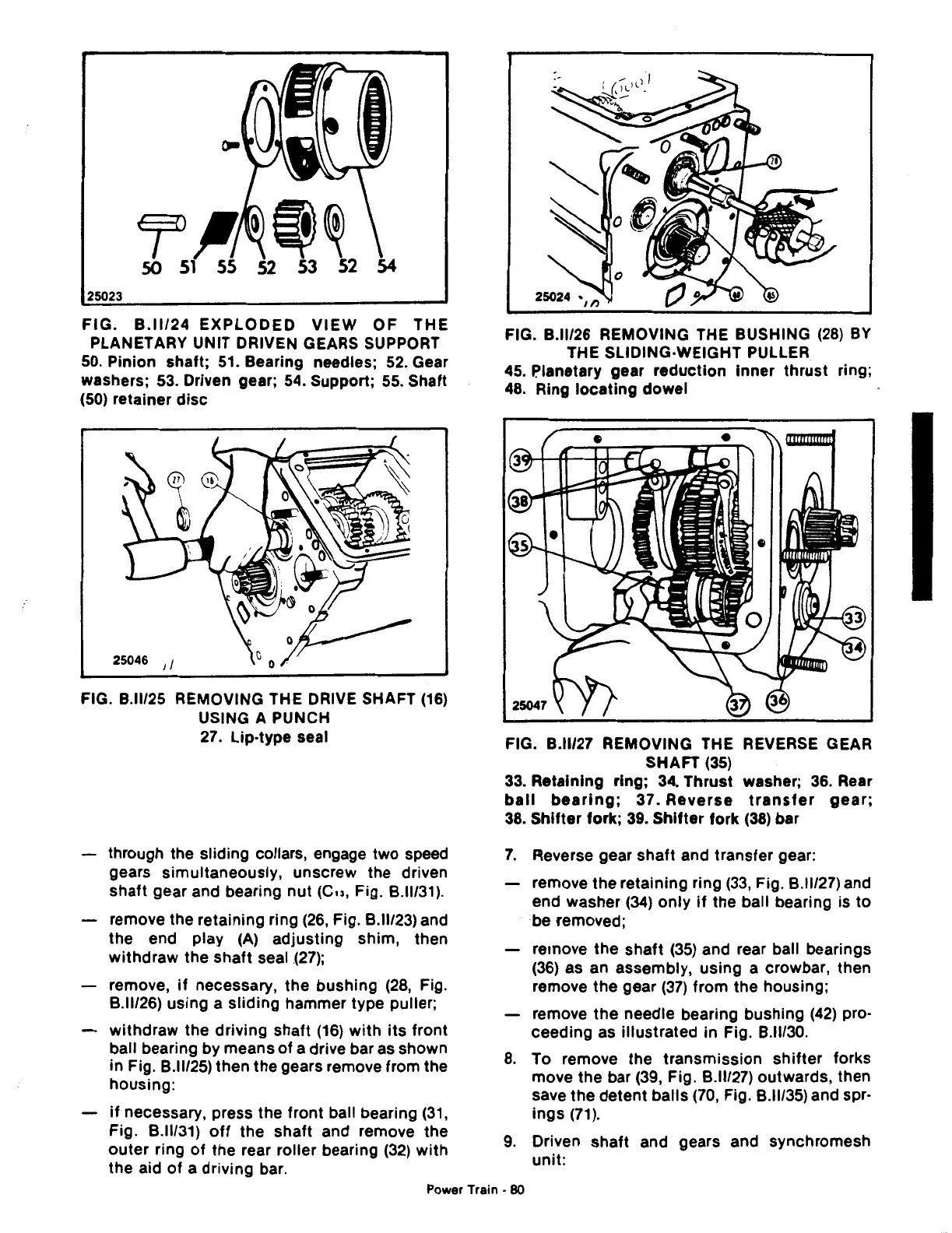

FIG. B.ll/27 REMOVING THE REVERSE GEAR

SHAFT

(35)

33.

Retaining ring; 34. Thrust washer; 36. Rear

ball

bearing;

37.

Reverse

transfer

gear;

38.

Shifter fork;

39.

Shifter

fork

(38)

bar

7.

Reverse gear shaft and transfer gear:

remove the retaining ring

(33,

Fig.

8.11127)

and

end washer

(34)

only

if

the ball bearing is

to

be removed;

remove the shaft

(35)

and rear ball bearings

(36)

as an assembly, using a crowbar, then

remove the gear

(37)

from the housing;

remove

the

needle bearing bushing

(42)

pro-

ceeding as illustrated in Fig.

8.11/30.

8.

To remove the transmission

shifter

forks

move the bar

(39,

Fig.

8.11/27)

outwards, then

save the detent balls

(70,

Fig.

8.11/35)

and spr-

ings

(71).

9.

Driven shaft and gears and synchromesh

unit:

Power

Train·

80

Loading...

Loading...