ding

to

a

pull

scale reading

of

4.4

to

6.6 lbs.

(19.5

to

29.4

N).

This

rolling

torque can be

checked by

wounding

a cord around the

dif·

ferential housing and

connecting

it

to

a pull

scale. ·

5.

Check

the

backlash between ring gear and pi-

nion

with

a dial

indicator

(Fig. B.X/15). If

backlash is not

within

limits

(.0059

to

.0078

in.) (.15

to

.20 mm), adjust as

follows:

(1)

BE

SURE BEARINGS CUPS ARE PRO·

PERL Y SEA TED against

adjusting

nuts

and

nuts

are

just

tight

enough

to

elimi-

nate all bearing end play.

(2)

To decrease backlash, loosen adjusting

nut on pinion side

of

differential

one

notch

and

tighten

other

nut

one notch.

Check backlash and repeat

if

necessary.

(3)

To increase backlash, loosen adjusting

nut on ring gear side

of

differential

one

notch. Check backlash and repeat as

necessary.

(4)

Tighten

differential

bearing cap screws

to specification. Recheck backlash.

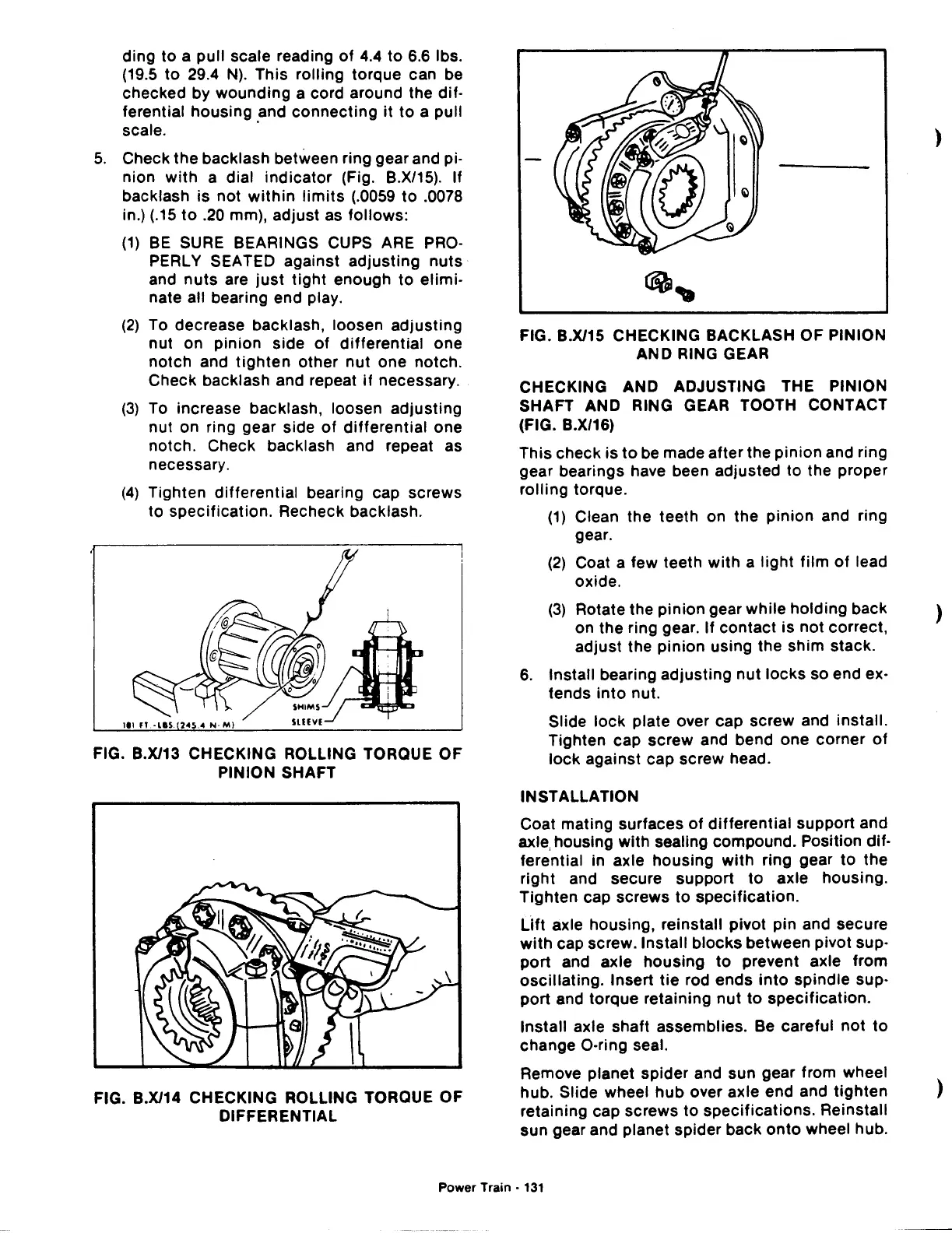

FIG. B.X/13 CHECKING ROLLING TORQUE OF

PINION SHAFT

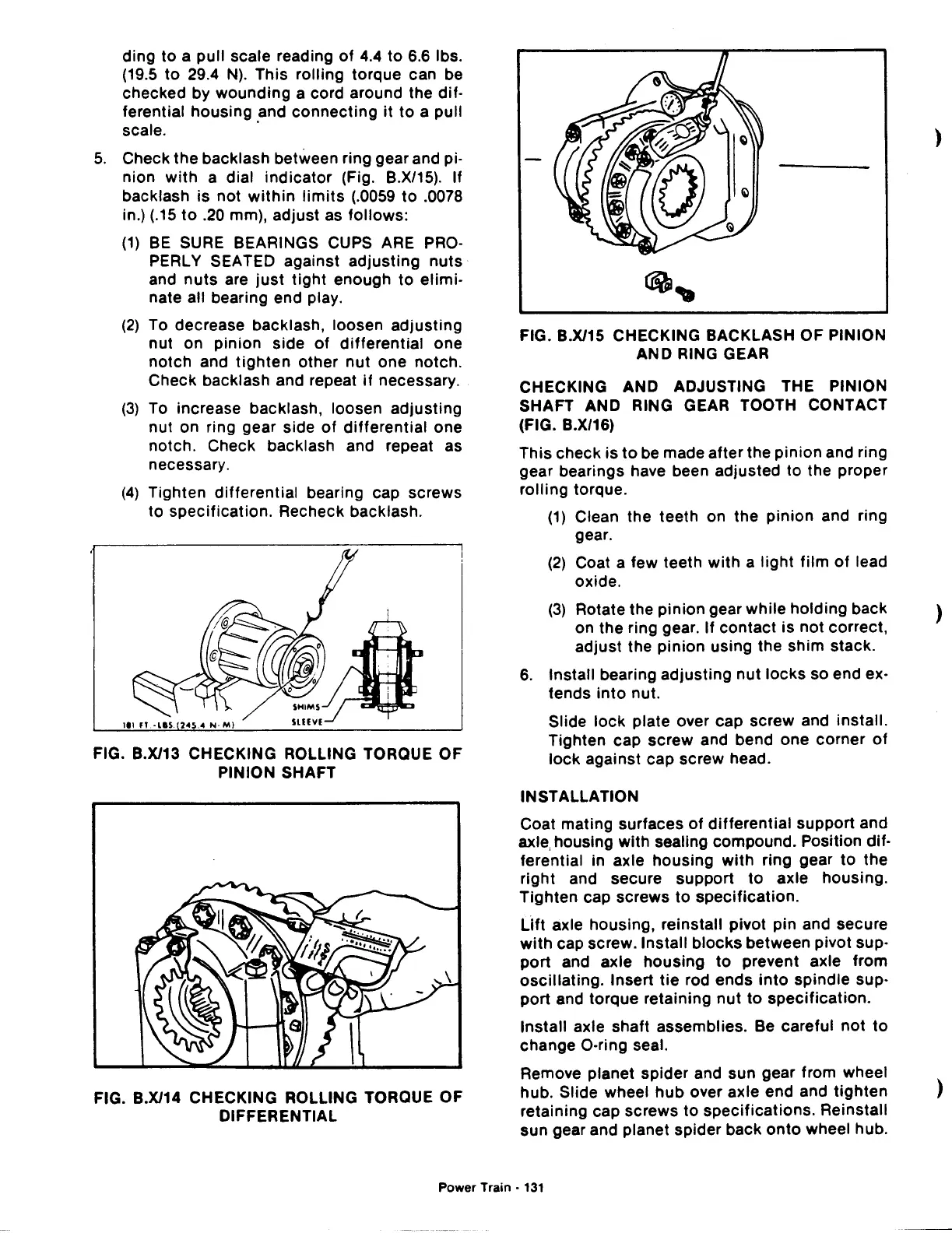

FIG. B.X/14 CHECKING ROLLING TORQUE

OF

DIFFERENTIAL

FIG. B.X/15 CHECKING BACKLASH OF PINION

AND RING GEAR

CHECKING AND ADJUSTING THE PINION

SHAFT AND RING GEAR TOOTH CONTACT

(FIG. B.X/16)

This check is

to

be made after the

pinion

and ring

gear bearings have been adjusted to the proper

rolling

torque.

(1)

Clean the teeth on the pinion and ring

gear.

(2)

Coat a few teeth

with

a

light

film

of

lead

oxide.

)

(3)

Rotate the

pinion

gear

while

holding back )

on the ring gear. If contact

is

not

correct,

adjust

the

pinion

using the shim stack.

6.

Install bearing adjusting

nut

locks

so end ex-

fends

into

nut.

Slide

lock

plate over cap screw and

install.

Tighten cap screw and bend one corner

of

lock

against cap screw head.

INSTALLATION

Coat mating surfaces

of

differential

support and

axle, housing with sealing compound. Position

dif·

ferential in axle housing

with

ring gear

to

the

right

and secure support

to

axle housing.

Tighten

cap screws

to

specification.

Lift

axle housing, reinstall pivot

pin

and secure

with

cap screw. Install

blocks

between pivot sup·

port

and axle

housing

to

prevent axle from

oscillating.

Insert

tie

rod ends

into

spindle sup-

port and torque retaining

nut

to

specification.

Install axle shaft assemblies. Be careful

not

to

change O·ring seal.

Remove planet spider and sun gear from wheel

hub. Slide wheel

hub

over axle end and

tighten

retaining cap screws

to

specifications.

Reinstall

sun gear and planet spider back

onto

wheel hub.

)

Power Train •

131

Loading...

Loading...