C.l POWER STEERING (POWER ASSISTED)

INTRODUCTION

The

power

steering

system

comprises

the

following

main parts: (Fig. C.l/1)

1. The

oil

reservoir (Item

16)

containing

the

filter

with

replaceable element.

2.

The hydraulic

pump

(Item

8)

driven by the

engine

timing

gear.

3.

The pressure valve, incorporated in the

hydraulic pump,

allows

the steering

of

the

tractor

when the

pump

is

inoperative or the

engine has stopped, and regulates the

pressure.

4.

The operating

cylinder

with

double-acting

ram (Item

7)

and

built-in

control

valve, install·

ed in parallel

with

drag link.

5.

Oil pipes and hoses

connecting

the pump

to

the

cylinder

circuit.

There are

two

different

versions of the power

steering cylinder. Cylinder assemblies are inter-

changeable, but

components

are not.

OPERATION (UTB)

Oil

drawn from independent reservoir, position-

ed above engine, is transferred under pressure

to

cylinder

inlet

port. Force inacted upon steering

wheel

during

turn

is

directed

to

control

valve

spool.

Spool movement

allows

pressure upon

cylinder

piston

aiding

direction

of

turn.

1. NEUTRAL POSITION (A, FIG. C.l/2)

When ball

stud

is

subjected

to

side pressure

lower

than preload of reaction spring, control

valve remains on a

floating

balanced

position

between

shoulders

of

valve spool

(41)

because

of

force

exercised

by springs

(30)

and

(36).

In

this

condition,

ports

(I)

and

(L)

are open

allowing

free

flow

of

fluid.

Oil

delivered by

pump

will

flow

back

into

oil

reservoir

through

cylinder

chambers

(E)

and (F) and line

(40).

2. RETRACTED

POSITION-LEFT

TURN

(8,

FIG. C.l/2)

If

front

ball

stud

(17)

is

subjected

to

a force ac-

ting

on

piston

(43)

and exceeding preloading

of

reaction

spring

(30),

control

valve spool moves in

same

direction

with

respect

to

cylinder

rod

(9);

this

will

restrict

and,

if

load is at

maximum

inten-

sity,

it

will

shut

off

oil

flow

through

port

(I);

con-

sequently, pressure exercised by oil in

minor

chamber

(E)

increases and forces

piston

(43)

to

retract

cylinder

rod

(9).

Oil contained in

opposite

chamber

(H)

flows

freely

into

reservoir through

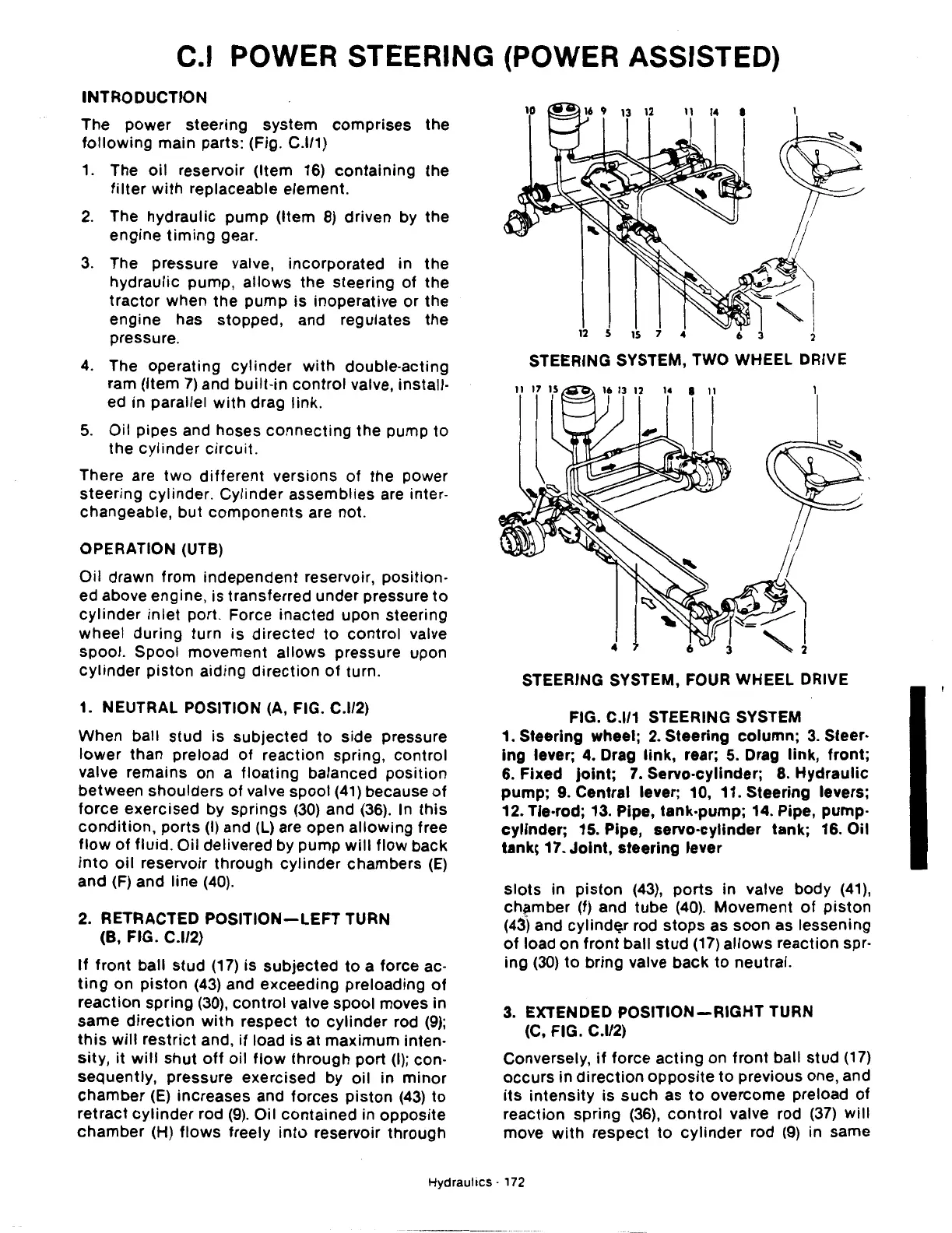

STEERING SYSTEM, TWO WHEEL DRIVE

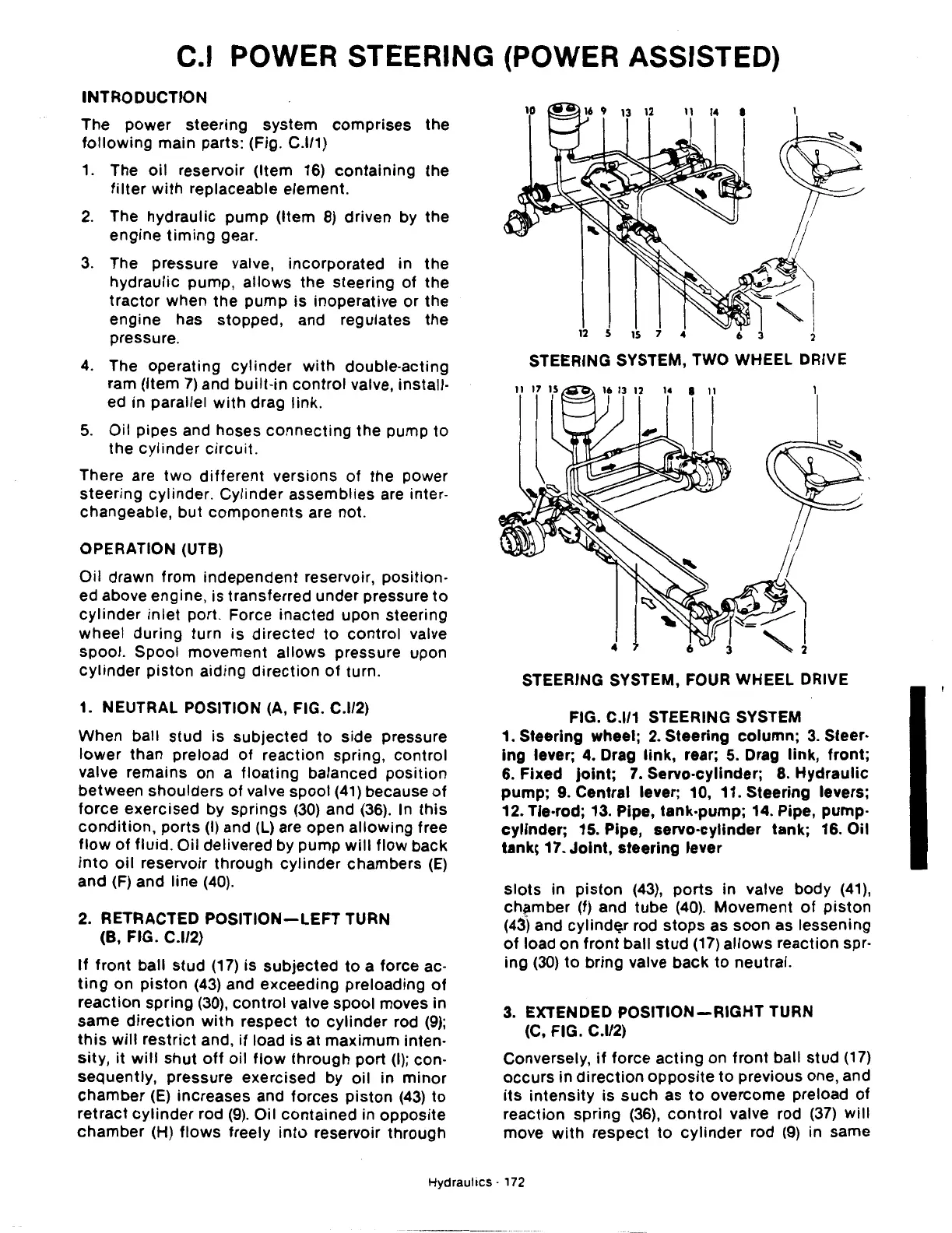

STEERING SYSTEM, FOUR WHEEL DRIVE

FIG. C.l/1 STEERING SYSTEM

1. Steering wheel; 2. Steering

column;

3.

Steer·

lng

lever; 4. Drag

link,

rear;

5.

Drag link,

front;

6.

Fixed

joint;

7.

Servo·cylinder;

8.

Hydraulic

pump;

9. Central lever; 10, 11. Steering levers;

12. Tle·rod; 13. Pipe, tank·pump; 14. Pipe, pump-

cylinder;

15. Pipe, servo·cylinder tank; 16. Oil

tank\ 17.

Joint,

steering lever

slots

in

piston

(43),

ports

in valve body

(41),

chamber (f) and

tube

(40).

Movement

of

piston

(43) and cylindQ.r rod

stops

as soon as lessening

of

load on

front

ball

stud

(17)

allows

reaction spr-

ing

(30)

to

bring valve

back

to

neutral.

3.

EXTENDED

POSITION-RIGHT

TURN

(C, FIG. C.l/2)

Conversely,

if

force

acting

on

front

ball stud

(17)

occurs

in

direction

opposite

to

previous one, and

its

intensity

is

such

as

to

overcome preload

of

reaction spring

(36),

control

valve rod

(37)

will

move

with

respect

to

cylinder

rod

(9)

in same

Hydraulics

· 172

Loading...

Loading...