55362

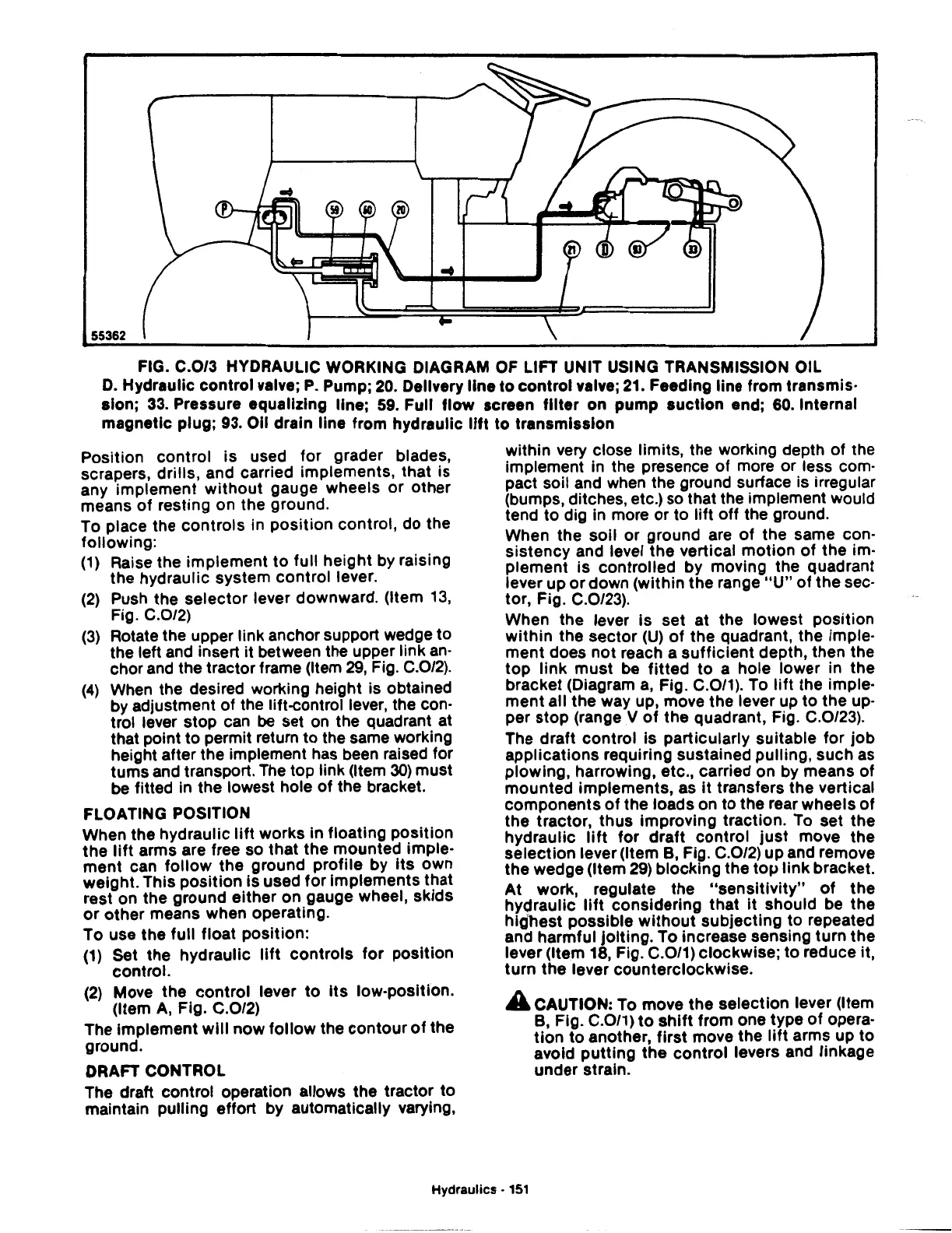

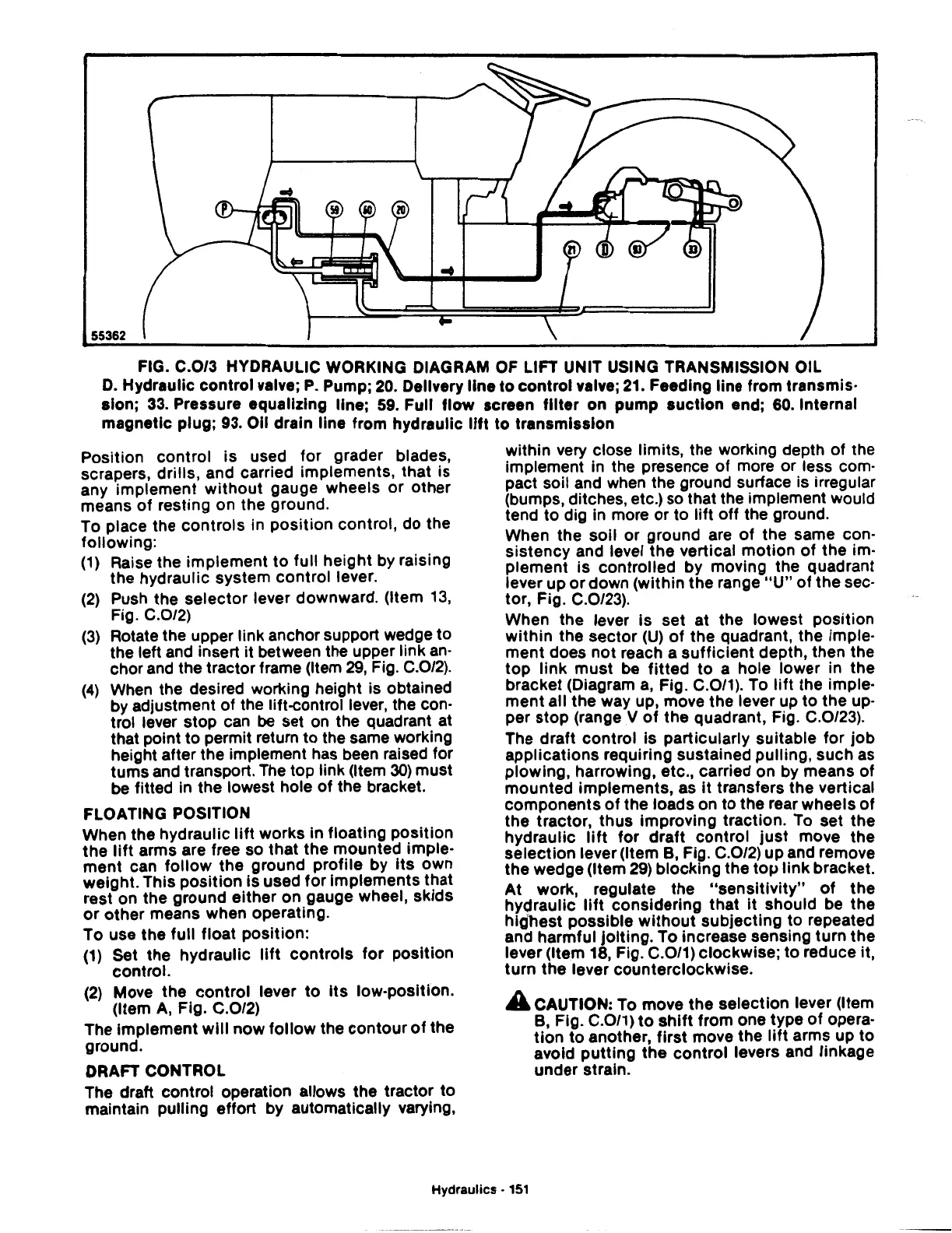

FIG. C.0/3 HYDRAULIC WORKING DIAGRAM OF LIFT UNIT USING TRANSMISSION OIL

D.

Hydraulic control valve;

P.

Pump;

20.

Delivery

line

to control valve;

21.

Feeding line from transmis·

sion;

33.

Pressure equalizing line;

59.

Full

flow

screen

filter

on pump suction end;

60.

Internal

magnetic plug;

93.

Oil drain line from hydraulic

lift

to transmission

Position control is used for grader blades,

scrapers, drills, and carried implements, that is

any implement

without

gauge wheels or other

means

of

resting on the ground.

To place the controls in position control, do the

following:

(1)

Raise the implement

to

full height by raising

the hydraulic system control lever.

(2)

Push the selector lever downward. (Item

13,

Fig. C.0/2)

(3)

Rotate the upper link anchor support wedge to

the left and insert it between the upper link

an·

chor and the tractor frame (Item

29,

Fig. C.0/2).

(4)

When

the desired working height is obtained

by adjustment

of

the lift-control lever, the con·

trol lever stop can

be

set

on

the quadrant at

that point

to

permit return to the same working

height after the implement has been raised for

turns and transport. The top link (Item

30)

must

be

fitted in the lowest hole of the bracket.

FLOATING POSITION

When the hydraulic

lift

works in floating position

the

lift

arms are free so that the mounted imple·

ment can

follow

the ground profile by Its own

weight. This

position

is used

for

implements that

rest on the ground either on gauge wheel, skids

or

other means when operating.

To use the full float position:

(1)

Set the hydraulic

lift

controls

for

position

control.

(2)

Move the control lever

to

Its low-position.

(Item

A,

Fig. C.0/2)

The Implement

will

now

follow

the contour

of

the

ground.

DRAFT CONTROL

The draft control operation allows the tractor to

maintain pulling effort by automatically varying,

within very close limits, the working depth

of

the

implement in the presence

of

more or less com·

pact soil and when the ground surface is irregular

(bumps, ditches, etc.) so that the implement would

tend to dig in more or to lift off the ground.

When the soil

or

ground are

of

the same con-

sistency and level the vertical motion

of

the im·

plement is controlled by moving the quadrant

lever up

or

down (within the range

"U"

of

the sec·

tor, Fig. C.0/23).

When the lever Is set at the lowest position

within

the sector

(U)

of

the quadrant, the imple·

ment does not reach a

sufficient

depth, then the

top

link

must

be

fitted

to

a hole lower in the

bracket (Diagram

a,

Fig. C.0/1). To

lift

the imple·

ment all the way up, move the lever up

to

the up·

per stop (range V

of

the quadrant, Fig. C.0/23).

The draft control is particularly suitable for job

applications requiring sustained pulling, such

as

plowing, harrowing, etc., carried on by means

of

mounted implements, as

it

transfers the vertical

components

of

the loads on to the rear wheels

of

the tractor, thus improving traction. To set the

hydraulic

lift

for

draft

control just move the

selection lever (Item

B,

Fig. C.0/2) up and remove

the wedge (Item

29)

blocking the

top

link

bracket.

At

work, regulate the

"sensitivity"

of

the

hydraulic

lift

considering that

it

should be the

highest possible

without

subjecting to repeated

and harmful jolting. To increase sensing turn the

lever (Item

18,

Fig. C.0/1) clockwise; to reduce it,

turn the lever counterclockwise.

A CAUTION: To move the selection lever (Item

B,

Fig. C.0/1)

to

shift

from one type

of

opera·

tion

to

another, first move the

lift

arms up to

avoid putting

the

control levers and linkage

under strain.

Hydraulics •

151

Loading...

Loading...