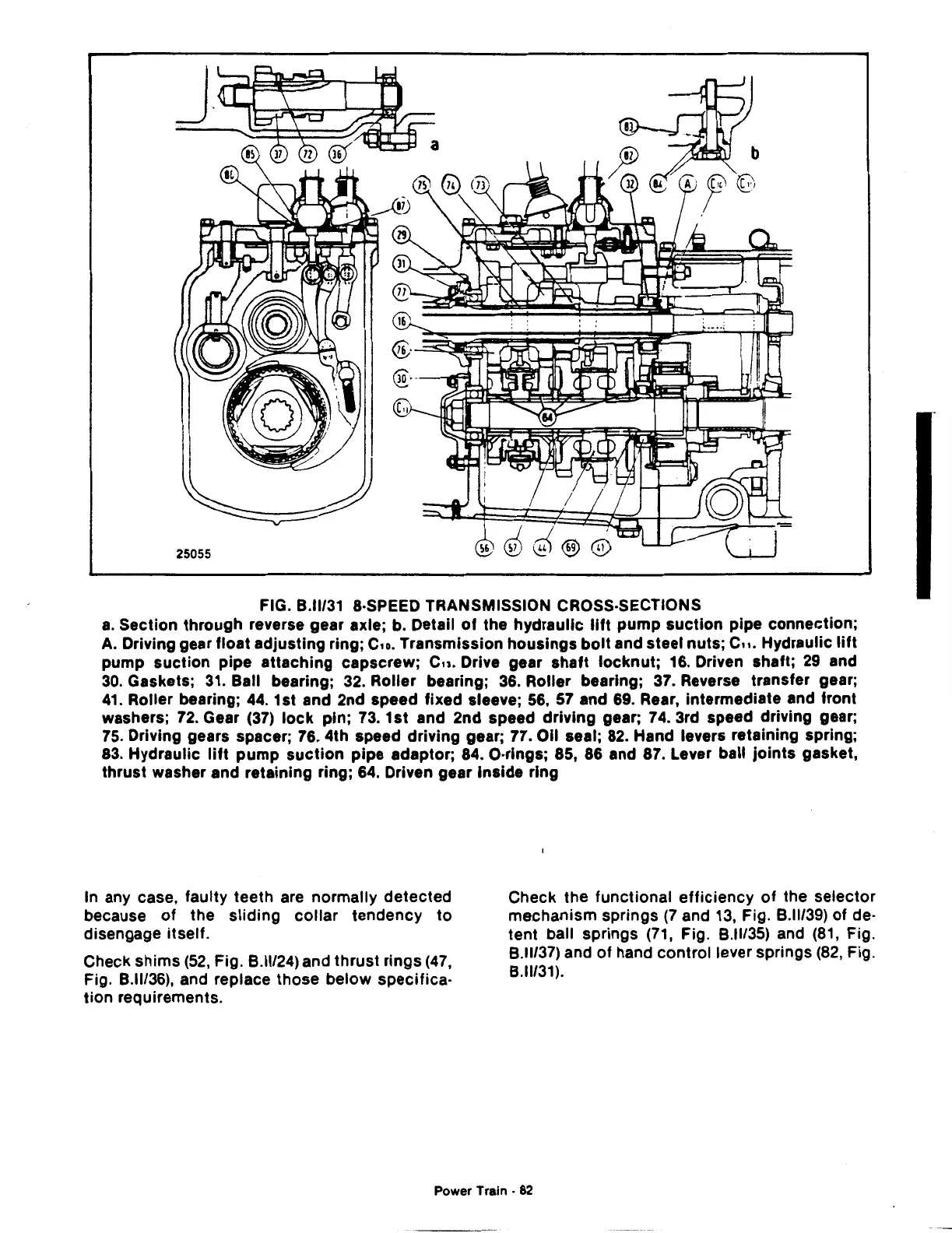

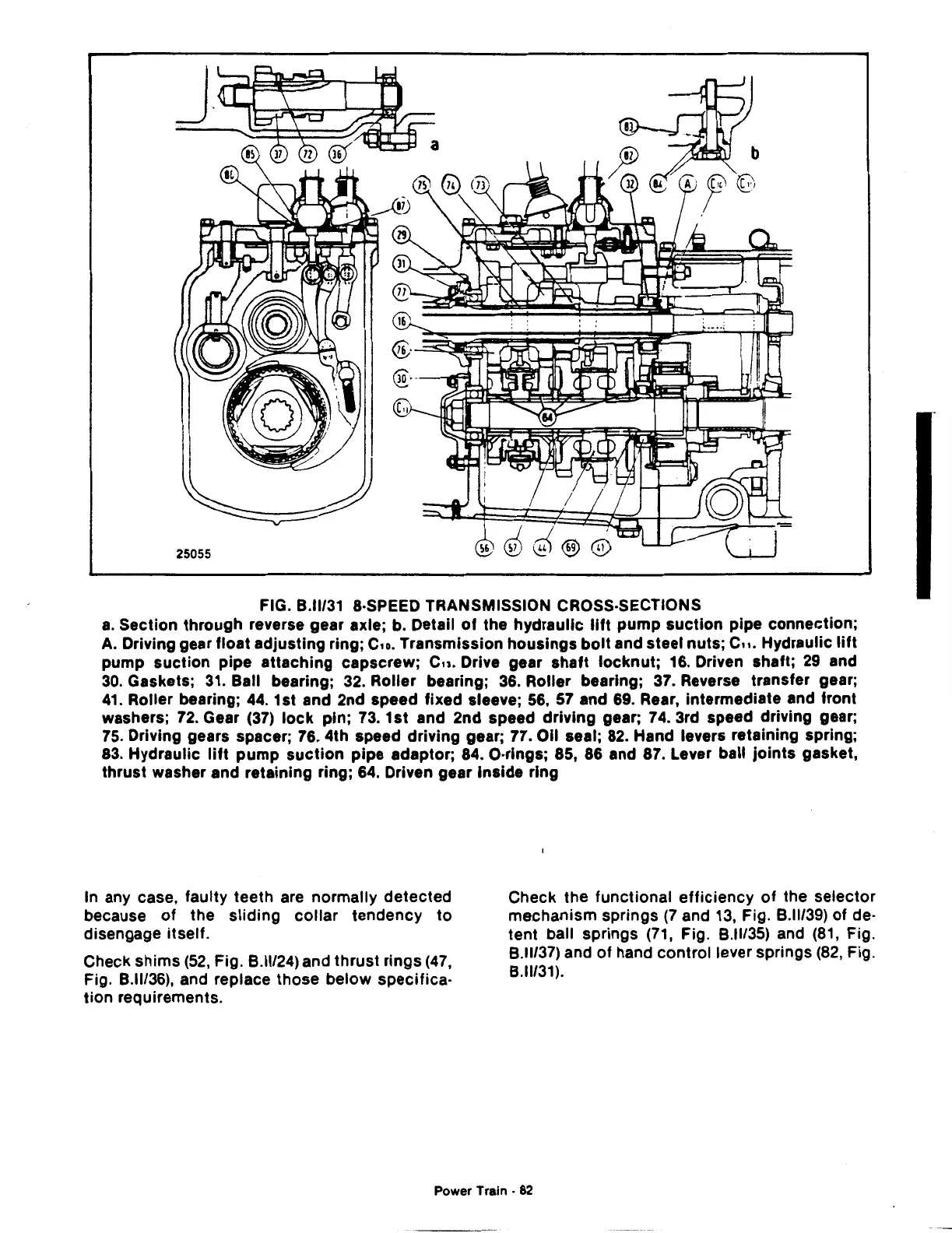

FIG.

8.11/31

&·SPEED TRANSMISSION CROSS·SECTIONS

a.

Section through reverse gear axle; b. Detail

of

the hydraulic

lift

pump suction pipe connection;

A.

Driving gear float adjusting ring;

C1o.

Transmission housings

bolt

and steel nuts;

C11.

Hydraulic

lift

pump suction pipe attaching capscrew;

Cu.

Drive gear shaft locknut; 16. Driven shaft;

29

and

30.

Gaskets;

31.

Ball bearing;

32.

Roller bearing;

36.

Roller bearing;

37.

Reverse transfer gear;

41.

Roller bearing;

44.

1st and 2nd speed fixed sleeve;

56,

57

and

69.

Rear, intermediate and front

washers;

72.

Gear

(37)

lock

pin; 73. 1st and 2nd speed driving gear; 74. 3rd speed driving gear;

75.

Driving gears spacer; 76. 4th speed driving gear; 77. Oil seal;

82.

Hand levers retaining spring;

83.

Hydraulic

lift

pump

suction

pipe adaptor; 84. O·rings; 85, 86 and 87. Lever ball joints gasket,

thrust washer and retaining ring;

64.

Driven gear Inside ring

In

any case, faulty teeth are normally detected

because

of

the

sliding

collar

tendency

to

disengage itself.

Check shims

(52,

Fig.

8.11124)

and thrust rings

(47,

Fig.

8.11/36),

and replace those below specifica·

tion requirements.

Check the functional

efficiency

of

the selector

mechanism springs

(7

and

13,

Fig.

8.11139)

of

de·

tent ball springs

(71,

Fig.

8.11/35)

and

(81,

Fig.

8.11137)

and

of

hand control lever springs

(82,

Fig.

8.11131).

Power Train •

82

Loading...

Loading...