B

80

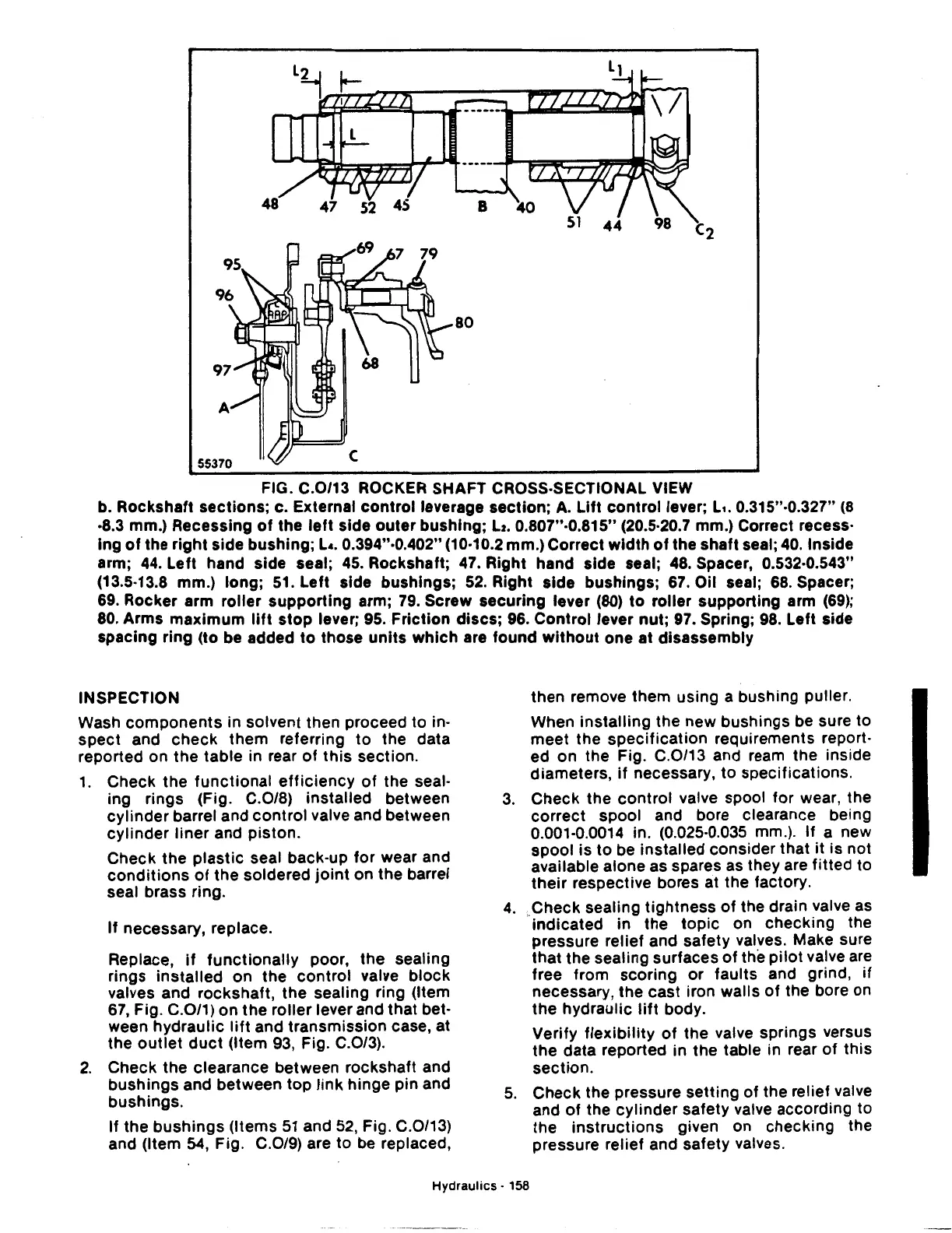

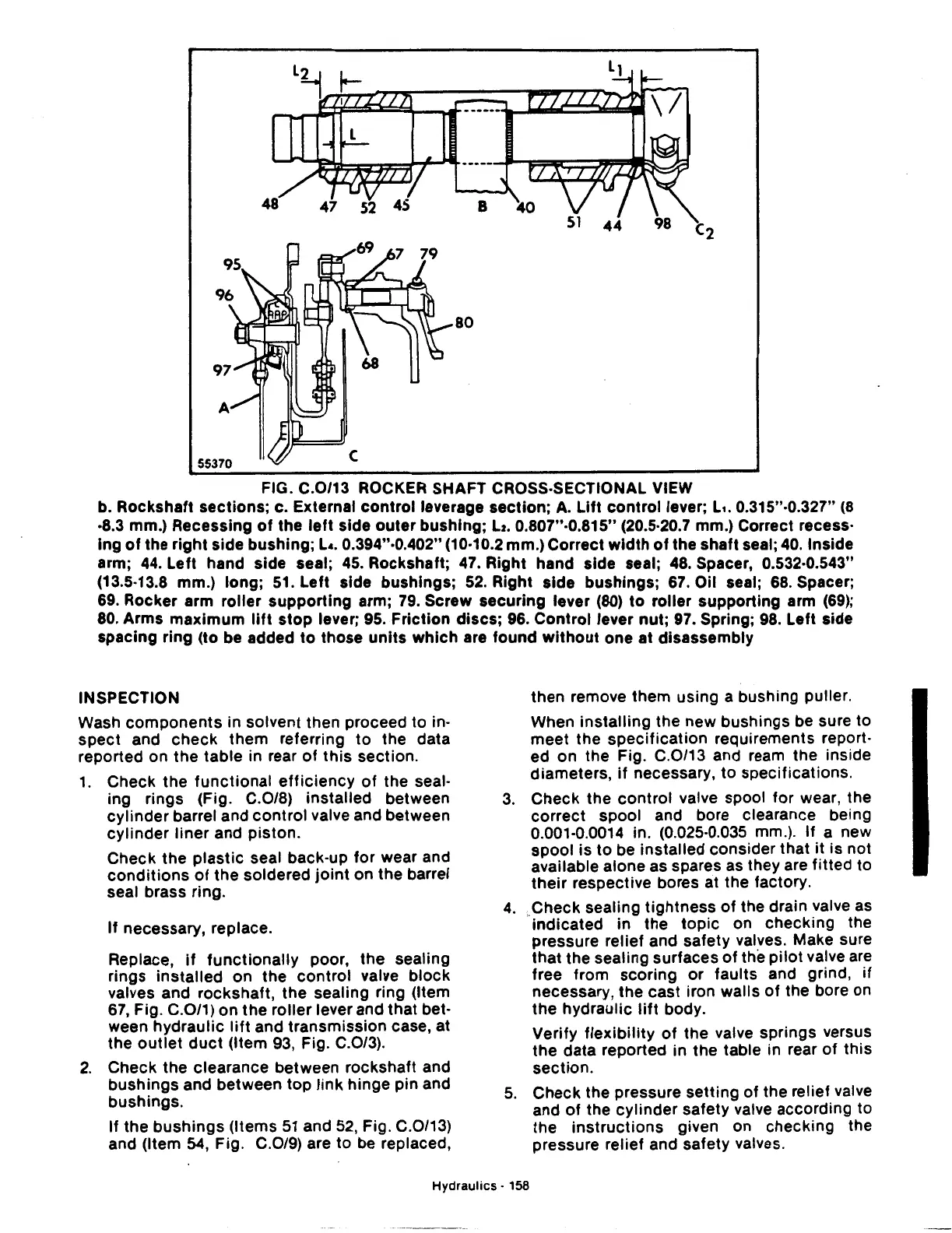

FIG. C.0/13 ROCKER SHAFT CROSS-SECTIONAL VIEW

b. Rockshaft sections; c. External

control

leverage section;

A.

Lift

control

lever; L

•.

0.315"·0.327"

(8

·8.3 mm.) Recessing

of

the

left

side

outer

bushing;

Lz.

0.807"·0.815" (20.5·20.7 mm.) Correct recess·

ing

of

the

right

side bushing; L •. 0.394"·0.402" (10·10.2 mm.) Correct

width

of

the shaft seal;

40.

Inside

arm; 44. Left hand side seal;

45.

Rockshaft; 47. Right hand side seal; 48. Spacer, 0.532·0.543"

(13.5·13.8 mm.)

long;

51.

Left

side bushings;

52.

Right side bushings; 67. Oil seal; 68. Spacer;

69. Rocker arm

roller

supporting

arm; 79. Screw securing lever (80)

to

roller supporting arm

(69);

80. Arms

maximum

lift

stop

lever; 95.

Friction

discs;

96.

Control

lever nut; 97. Spring; 98. Left side

spacing ring (to be added

to

those

units

which

are found

without

one at disassembly

INSPECTION

Wash

components

in solvent then proceed

to

in-

spect

and

check

them

referring

to

the data

reported on

the

table in rear

of

this

section.

1.

Check

the

functional

efficiency

of

the seal-

ing rings (Fig. C.0/8) installed between

cylinder

barrel and

control

valve and between

cylinder

liner

and

piston.

Check

the

plastic

seal back-up

for

wear and

conditions

of

the

soldered

joint

on

the

barrel

seal brass ring.

If

necessary, replace.

Replace,

if

functionally

poor,

the

sealing

rings

installed

on

the

control

valve

block

valves and rockshaft,

the

sealing ring (Item

67, Fig. C.0/1)

on

the

roller

lever and

that

bet-

ween

hydraulic

lift

and

transmission

case, at

the

outlet

duct

(Item 93, Fig. C.0/3).

2.

Check

the

clearance between rockshaft and

bushings

and between

top

link

hinge pin and

bushings.

If

the

bushings

(Items

51

and

52,

Fig. C.0/13)

and (Item

54,

Fig. C.0/9) are

to

be replaced,

then

remove them using a bushing puller.

When

installing

the

new bushings be sure

to

meet

the

specification

requirements report-

ed on the Fig. C.0/13 and ream

the

inside

diameters,

if

necessary,

to

specifications.

3.

Check

the

control

valve spool

for

wear, the

correct

spool and bore clearance being

0.001-0.0014 in. (0.025-0.035 mm.). If a new

spool

is

to

be installed consider that

it

is not

available alone as spares as they are

fitted

to

their

respective bores at the factory.

4.

.Check sealing

tightness

of

the drain valve as

indicated

in the

topic

on

checking

the

pressure relief and safety valves. Make sure

that

the sealing surfaces

of

the

pilot

valve are

free from

scoring

or

faults and grind,

if

necessary, the

cast

iron walls

of

the bore on

the

hydraulic

lift

body.

Verify

flexibility

of

the

valve springs versus

the

data reported in

the

table in rear

of

this

section.

5.

Check

the pressure

setting

of

the relief valve

and

of

the

cylinder

safety valve according to

the

instructions

given on checking the

pressure relief and safety valves.

Hydraulics·

158

Loading...

Loading...