55371

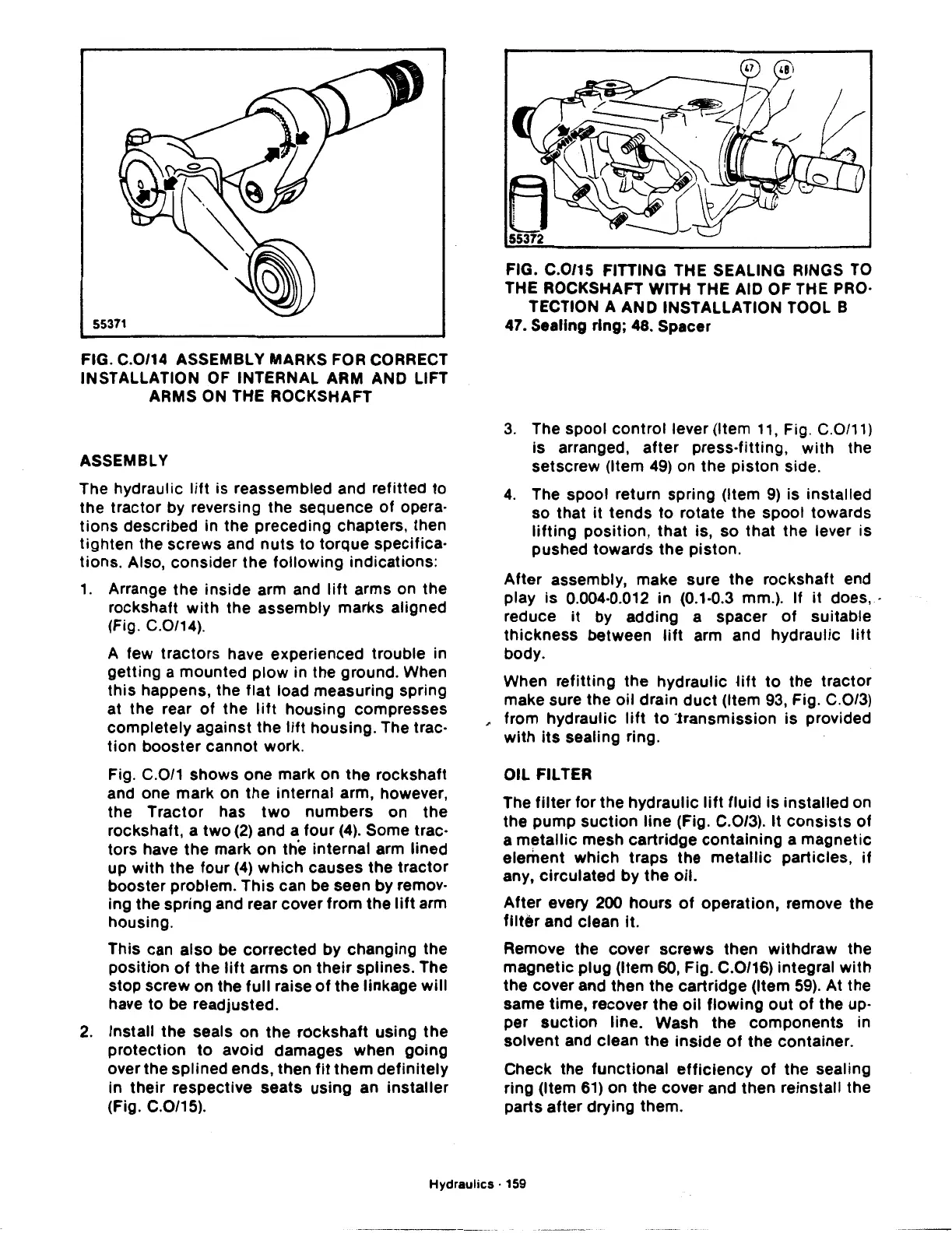

FIG. C.0/14 ASSEMBLY MARKS FOR CORRECT

INSTALLATION OF INTERNAL ARM AND LIFT

ARMS ON

THE

ROCKSHAFT

ASSEMBLY

The hydraulic

lift

is reassembled and refitted

to

the

tractor

by

reversing

the

sequence

of

opera·

tions

described

in the

preceding

chapters,

then

tighten

the

screws

and

nuts

to

torque

specifica-

tions.

Also,

consider

the

following

indications:

1.

Arrange

the

inside

arm and

lift

arms on

the

rockshaft

with

the

assembly

marks

aligned

(Fig. C.0/14).

A few

tractors

have

experienced

trouble

in

getting

a

mounted

plow

in

the

ground. When

this

happens, the

flat

load

measuring

spring

at

the

rear

of

the

lift

housing

compresses

completely

against

the

lift

housing.

The trac-

tion

booster

cannot

work.

Fig. C.0/1

shows

one

mark

on

the

rockshaft

and one

mark

on

the

internal arm, however,

the

Tractor

has

two

numbers

on

the

rockshaft, a

two

(2)

and a

four

(4). Some trac-

tors

have

the

mark

on

the

internal arm

lined

up

with

the

four

(4)

which

causes

the

tractor

booster

problem.

This

can be seen by remov-

ing

the

spring

and rear cover

from

the

lift

arm

housing.

This

can

also

be

corrected

by

changing

the

position

of

the

lift

arms

on

their

splines. The

stop

screw

on

the

full

raise

of

the

linkage

will

have

to

be readjusted.

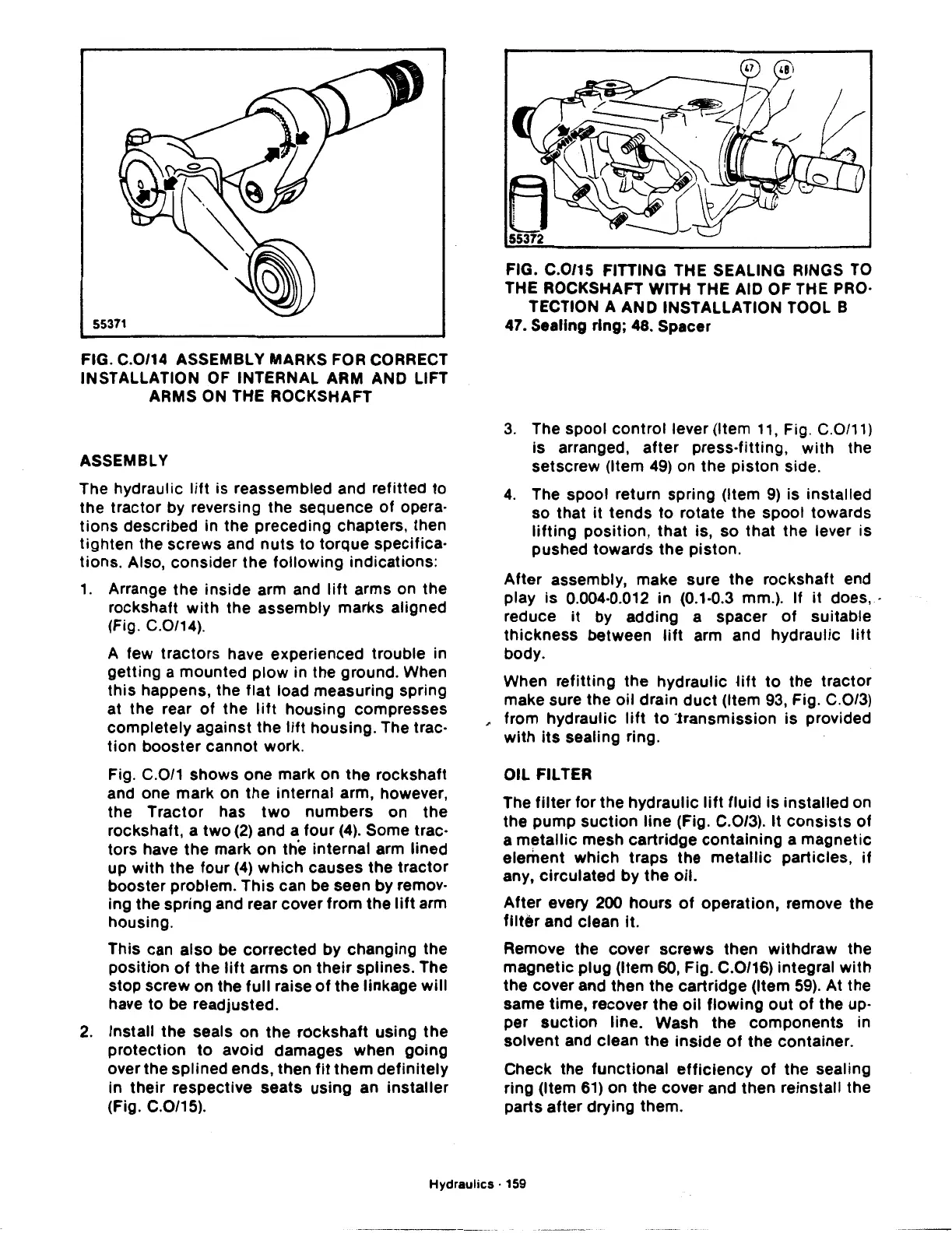

2.

Install

the

seals

on

the

rockshaft

using

the

protection

to

avoid damages when

going

over the

splined

ends,

then

fit

them

definitely

in

their

respective

seats

using

an

installer

(Fig. C.0/15).

FIG. C.0/15 FITTING THE SEALING RINGS TO

THE ROCKSHAFT WITH THE AID

OF

THE PRO·

TECTION A

AND

INSTALLATION TOOL B

47. Sealing

ring;

48. Spacer

3.

The spool

control

lever (Item

11,

Fig. C.0/11)

is arranged,

after

press-fitting,

with

the

setscrew

(Item 49) on

the

piston

side.

4.

The spool return

spring

(Item

9)

is

installed

so

that

it

tends

to

rotate

the

spool

towards

lifting

position,

that

is,

so

that

the

lever is

pushed

towards

the

piston.

After

assembly, make sure

the

rockshaft

end

play

is

0.004·0.012

in

(0.1·0.3 mm.).

If

it

does, ·

reduce

it

by

adding

a

spacer

of

suitable

thickness

between

lift

arm and

hydraulic

litt

body.

When

refitting

the

hydraulic

Hft

to

the

tractor

make sure

the

oil

drain

duct

(Item 93, Fig. C.0/3)

~

from

hydraulic

lift

to

'.transmission

is

provided

with

its

sealing ring.

OIL FILTER

The

filter

for

the

hydraulic

lift

fluid

is

installed

on

the

pump

suction

line

(Fig. C.0/3).

It

consists

of

a

metallic

mesh

cartridge

containing

a

magnetic

element

which

traps

the

metallic

particles,

if

any,

circulated

by

the

oil.

After

every 200

hours

of

operation,

remove

the

filter

and

clean

it.

Remove

the

cover

screws

then

withdraw

the

magnetic

plug

(Item 60, Fig. C.0/16) integral

with

the

cover and

then

the

cartridge

(Item 59).

At

the

same

time,

recover

the

oil

flowing

out

of

the

up·

per

suction

line. Wash

the

components

in

solvent

and clean

the

inside

of

the

container.

Check the

functional

efficiency

of

the

sealing

ring (Item 61) on

the

cover

and

then

reinstall

the

parts

after

drying

them.

Hydraulics · 159

Loading...

Loading...