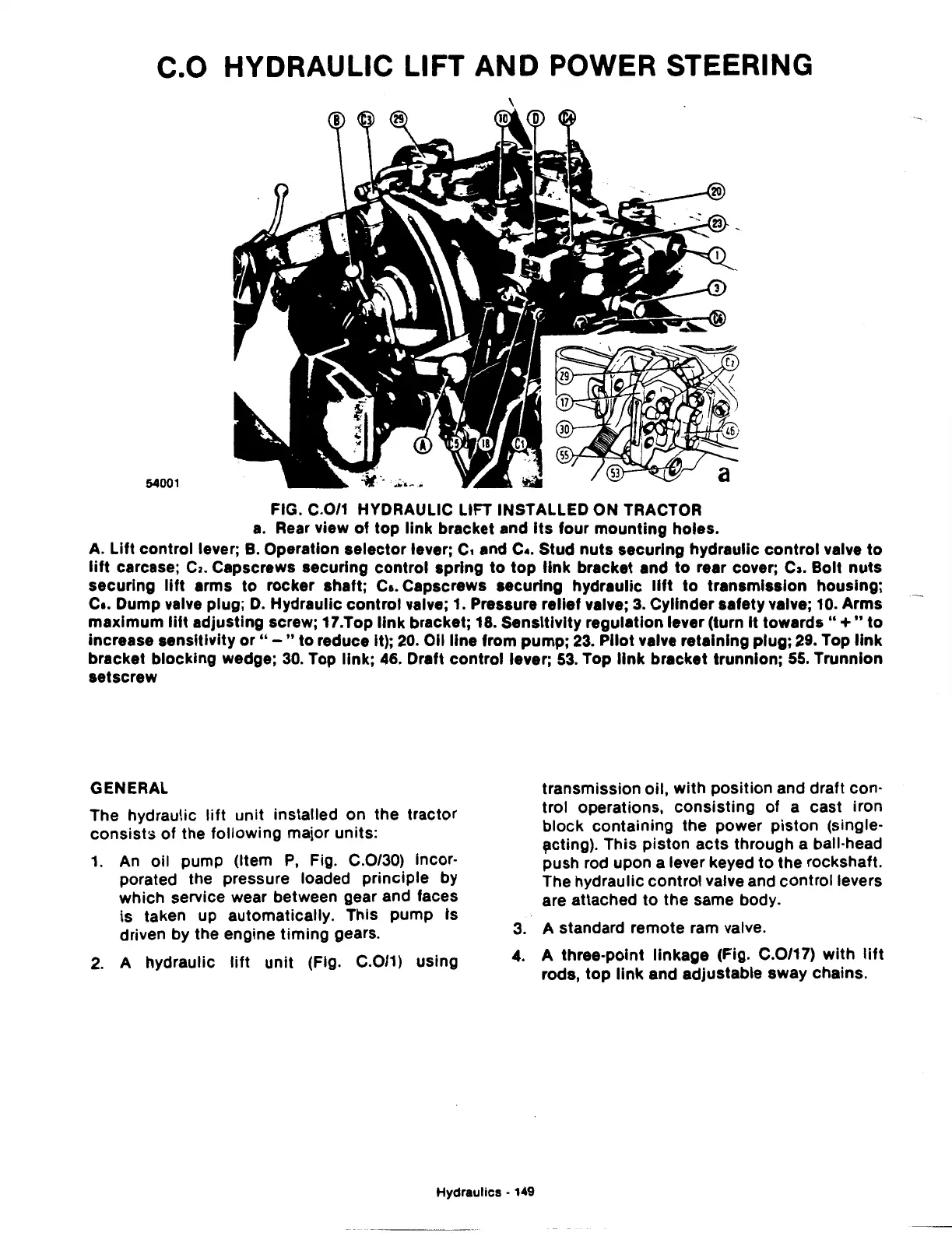

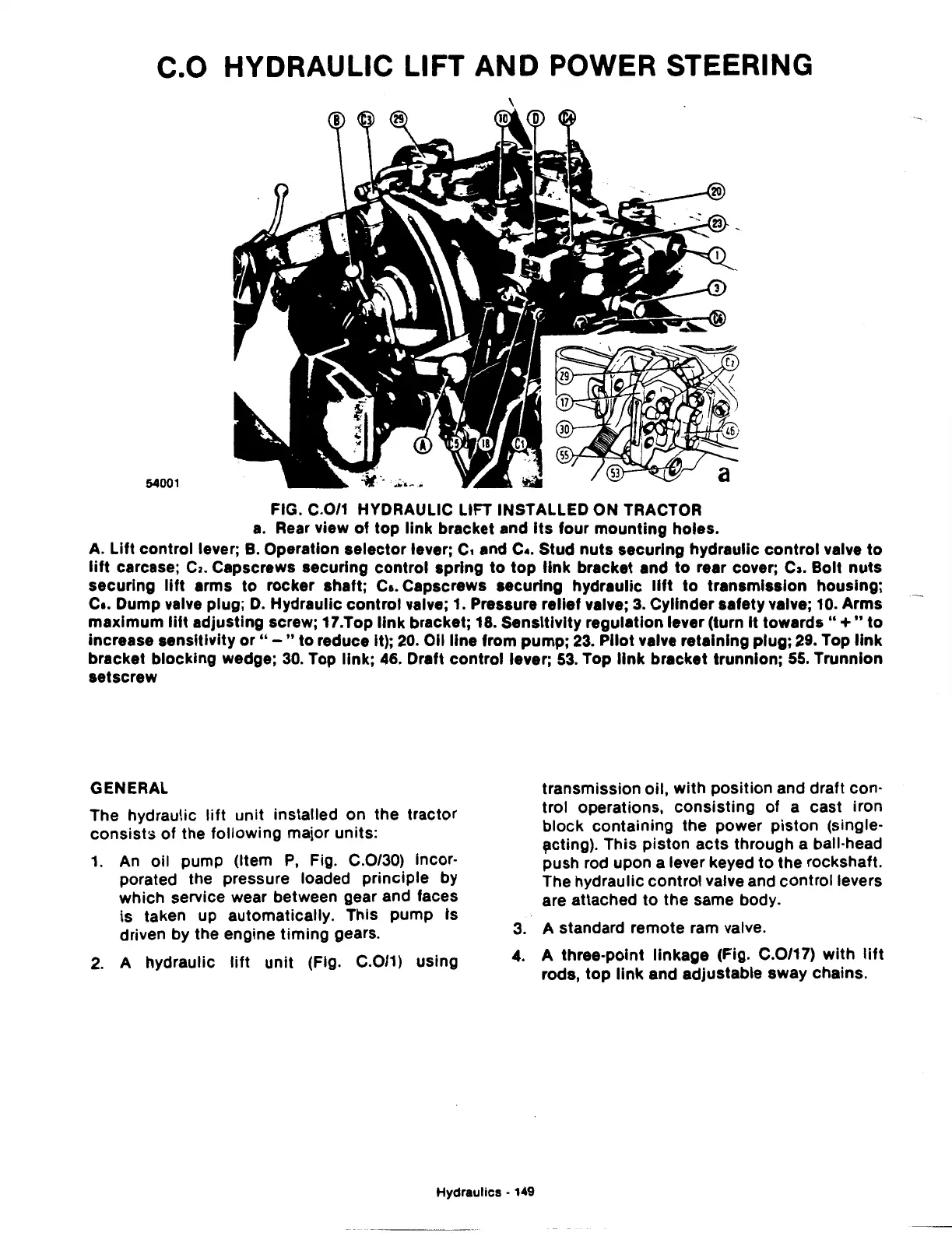

C.O HYDRAULIC LIFT AND POWER STEERING

54001

FIG. C.0/1 HYDRAULIC LIFT INSTALLED ON TRACTOR

a.

Rear view

of

top link bracket and

Its

four mounting holes.

A.

Lift control lever;

B.

Operation selector lever;

c,

and c

•.

Stud nuts securing hydraulic control valve

to

lift

carcase;

Ca.

Capscrews securing control spring

to

top

link

bracket and

to

rear cover; c,. Bolt

nuts

securing

lift

arms to rocker shaft;

Ca.

Capscrews securing hydraulic

lift

to

transmission housing;

c

•.

Dump valve plug;

D.

Hydraulic control valve;

1.

Pressure relief valve;

3.

Cylinder safety valve;

10.

Arms

maximum

lift

adjusting screw; 17.Top

link

bracket; 18. Sensitivity regulation lever (turn It

towards"+"

to

increase sensitivity

or"-"

to reduce It);

20.

Oil line from pump;

23.

Pilot valve retaining plug;

29.

Top

link

bracket blocking wedge;

30.

Top link; 46. Draft control lever;

53.

Top

link

bracket trunnion;

55.

Trunnion

setscrew

GENERAL

The hydraulic

lift

unit installed on the tractor

consists of the following major units:

1.

An

oil pump (Item

P,

Fig. C.0/30) incor-

porated the pressure loaded principle by

which service wear between gear and faces

is taken up automatically. This pump

ts

driven by the engine timing gears.

2.

A hydraulic

lift

unit

(Fig. C.0/1) using

transmission oil, with position and draft con-

trol operations, consisting

of

a cast iron

block containing the power piston (single-

,cting).

This piston acts through a ball-head

push rod upon a lever keyed to the rockshaft.

The hydraulic control valve and control levers

are attached

to

the same body.

3.

A standard remote ram valve.

4. A three-point linkage (Fig. C.0/17) with

lift

rods,

top

link

and adjustable sway chains.

Hydraulics • 149

Loading...

Loading...