\

is

locked

by

the

stop (0, Fig. B.IX/14). Measure

dimension

X and

check

on the drive

pinion

the

permissible

error

A.

A CAUTION: Measure

dimension

X

only

after

ad·

justing

the

spring

A2,

so

that

the bear-

ings

support

rotation

is

made using a

torque

indicator

handle wrench.

The shim

thickness

for the drive

pinion

should

be:

S2

= (X • A) in. (mm.).

Remove the plate and the drive

pinion

support

from

the device, the inner races

of

the bevel sup·

ports

and the drive pinion support.

To

reassembly the bevel pinion support

with

the

bevel pinion, insert on the bevel

pinion

a shim

and then press on the bevel

pinion

shaft the in·

ner race

of

the roller bearing (Item

51,

Fig.

B.IX/12).

1.

Introduce the bushings

(50)

the

shims

(16)

for

the drive

pinion

bearings and finally the bevel

pinion

support

(43).

2.

Press the bearing inner race

(51)

on the bevel

pinion.

3.

Fit on the support the oil ring

(48)

after

inser-

ting

the spring. Prior

to

pressing the sealing

will

be coated

with

lithium

base lubricant

grease in the spring location and on the seal·

ing lug.

4.

Fit the bevel pinion support cover

(59)

on the

pinions

support by

fully

tightening

the 3

screws and securing by circlips.

5.

Insert the splined flange

(47)

on the shaft,

then the washer

(46)

and

tighten

the splined

D

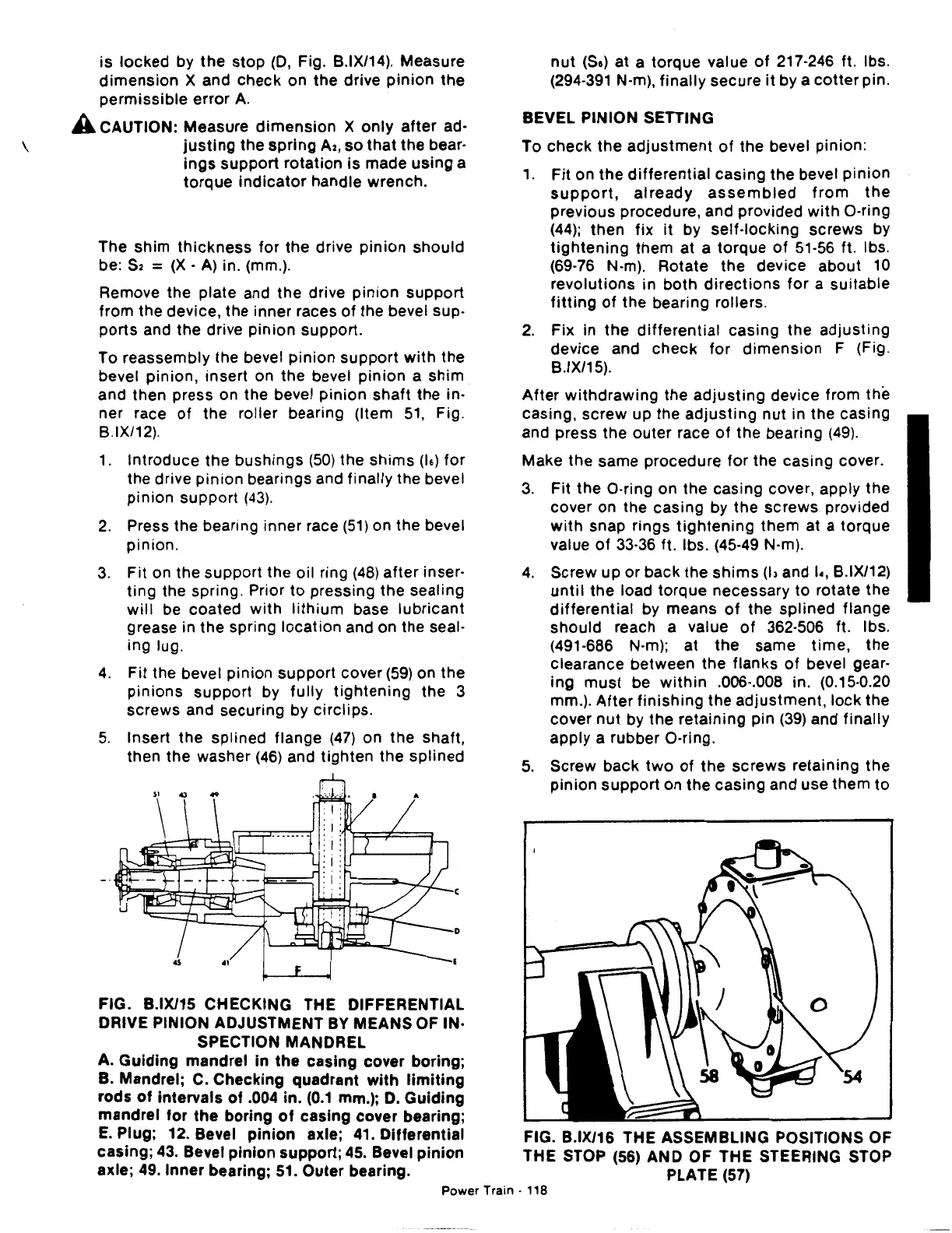

FIG. B.IX/15 CHECKING THE DIFFERENTIAL

DRIVE PINION ADJUSTMENT

BY

MEANS OF IN·

SPECTION MANDREL

A.

Guiding

mandrel In the casing cover boring;

B. Mandrel; C. Checking quadrant

with

limiting

rods

of

intervals

of

.004 in.

(0.1

mm.);

D.

Guiding

mandrel

for

the

boring

of

casing cover bearing;

E.

Plug; 12. Bevel

pinion

axle; 41. Differential

casing;

43.

Bevel

pinion

support; 45. Bevel

pinion

axle; 49.

Inner

bearing; 51. Outer bearing.

nut

(Se)

at a torque value

of

217·246 ft. lbs.

(294-391 N-m),

finally

secure

it

by a

cotter

pin.

BEVEL PINION SETTING

To

check

the

adjustment

of

the bevel pinion:

1.

Fit

on the

differential

casing the bevel

pinion

support,

already

assembled

from

the

previous procedure, and provided

with

0-ring

(44);

then

fix

it

by

self-locking

screws by

tightening

them at a torque

of

51-56 ft. lbs.

(69-76 N-m). Rotate the device about

10

revolutions

in both

directions

for

a suitable

fitting

of

the bearing rollers.

2.

Fix in

the

differential

casing the

adjusting

device and

check

for

dimension

F (Fig.

B.IX/15).

After

withdrawing

the

adjusting

device from the

casing, screw up the

adjusting

nut

in the casing

and press the outer race

of

the bearing

(49).

Make the same procedure

for

the casing cover.

3.

Fit the

0-ring

on the casing cover, apply the

cover on the casing by the

screws

provided

with

snap rings

tightening

them

at a torque

value

of

33-36 ft. lbs. (45-49 N-m).

4.

Screw up or back the

shims

(13

and

1.,

B.IX/12)

until

the load torque necessary

to

rotate the

differential

by means

of

the splined flange

should

reach a value

of

362-506 ft. lbs.

(491-686 N-m); at

the

same

time,

the

clearance between the flanks

of

bevel gear-

ing

must

be

within

.006·.008 in. (0.15·0.20

mm.).

After

finishing

the adjustment,

lock

the

cover

nut

by the retaining pin

(39)

and finally

apply a rubber

0-ring.

5.

Screw

back

two

of

the screws retaining

the

pinion

support

on the casing and use them

to

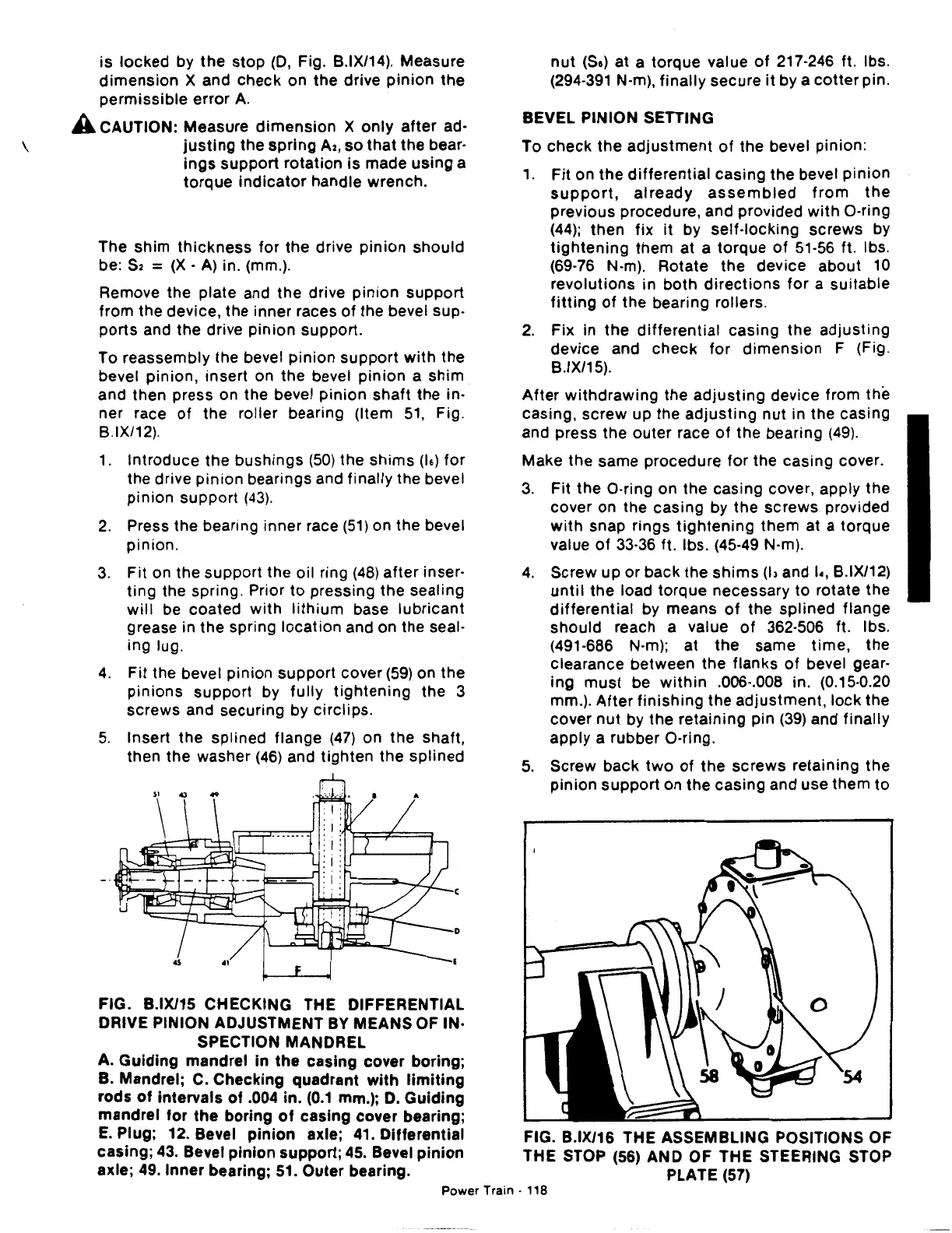

FIG. B.IX/16 THE ASSEMBLING POSITIONS OF

THE STOP (56) AND

OF

THE STEERING STOP

PLATE (57)

Power

Train·

118

Loading...

Loading...