15161

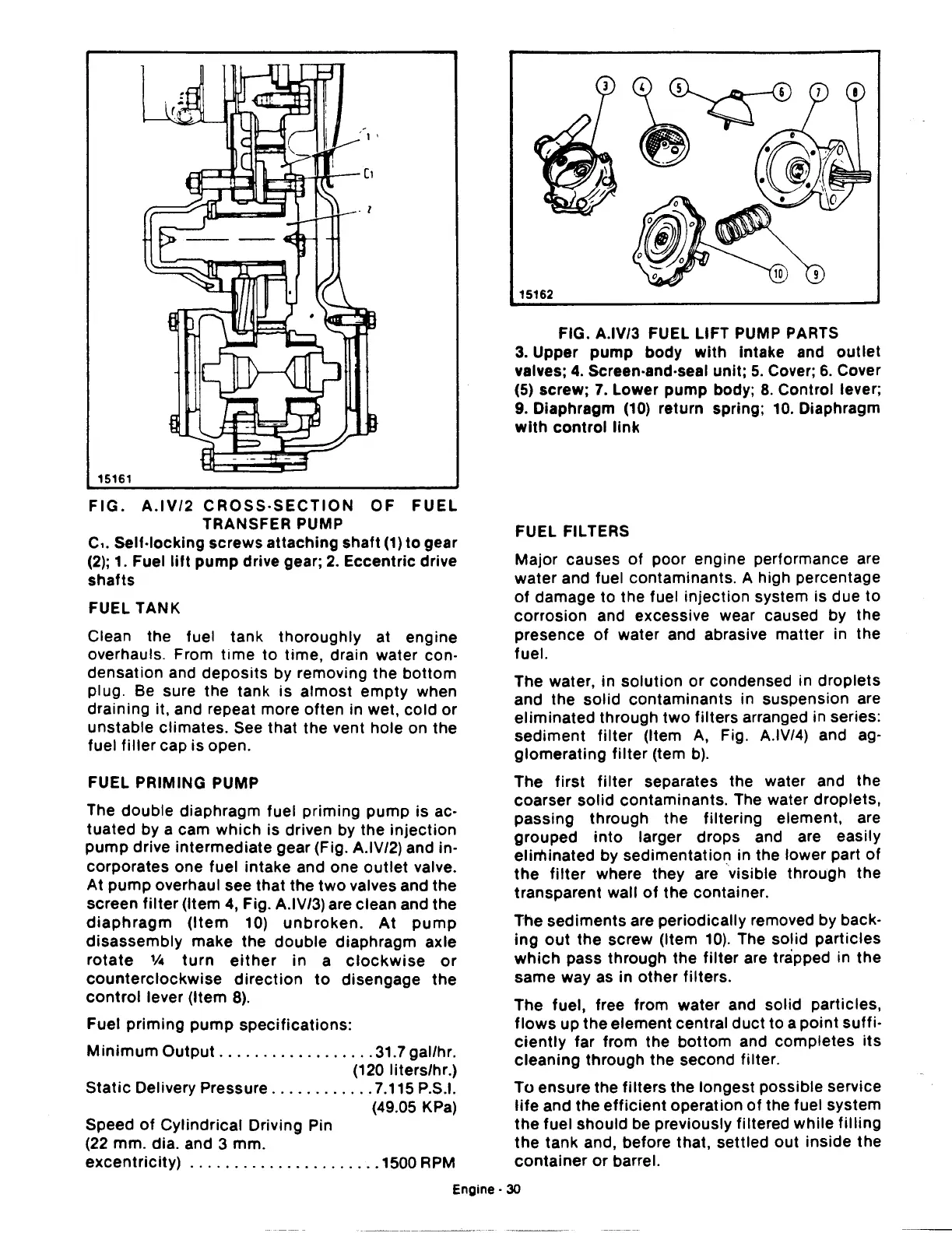

FIG.

A.IV/2

CROSS-SECTION

OF

FUEL

TRANSFER PUMP

c

..

Self-locking screws

attaching

shaft

(1)

to

gear

(2);

1. Fuel

lift

pump

drive gear;

2.

Eccentric drive

shafts

FUEL TANK

Clean the fuel tank thoroughly at engine

overhauls. From

time

to time, drain water con-

densation and

deposits

by removing the

bottom

plug. Be sure the tank is

almost

empty

when

draining it, and repeat more often in wet,

cold

or

unstable climates. See that the vent hole on the

fuel

filler

cap is open.

FUEL PRIMING PUMP

The

double

diaphragm fuel priming

pump

is ac-

tuated by a cam

which

is driven by the

injection

pump

drive

intermediate

gear (Fig. A.IV/2) and in-

corporates one fuel intake and one

outlet

valve.

At

pump

overhaul see that the

two

valves and the

screen

filter

(Item

4,

Fig. A.IV/3) are clean and the

diaphragm

(Item

10)

unbroken.

At

pump

disassembly

make the

double

diaphragm axle

rotate

1/4

turn

either

in

a

clockwise

or

counterclockwise

direction

to

disengage

the

control

lever (Item

8).

Fuel

priming

pump

specifications:

Minimum

Output

..................

31.7 gal/hr.

(120 liters/hr.)

Static

Delivery Pressure

............

7.115 P.S.I.

(49.05 KPa)

Speed

of

Cylindrical Driving Pin

(22

mm. dia. and 3 mm.

excentricity)

......................

1500

RPM

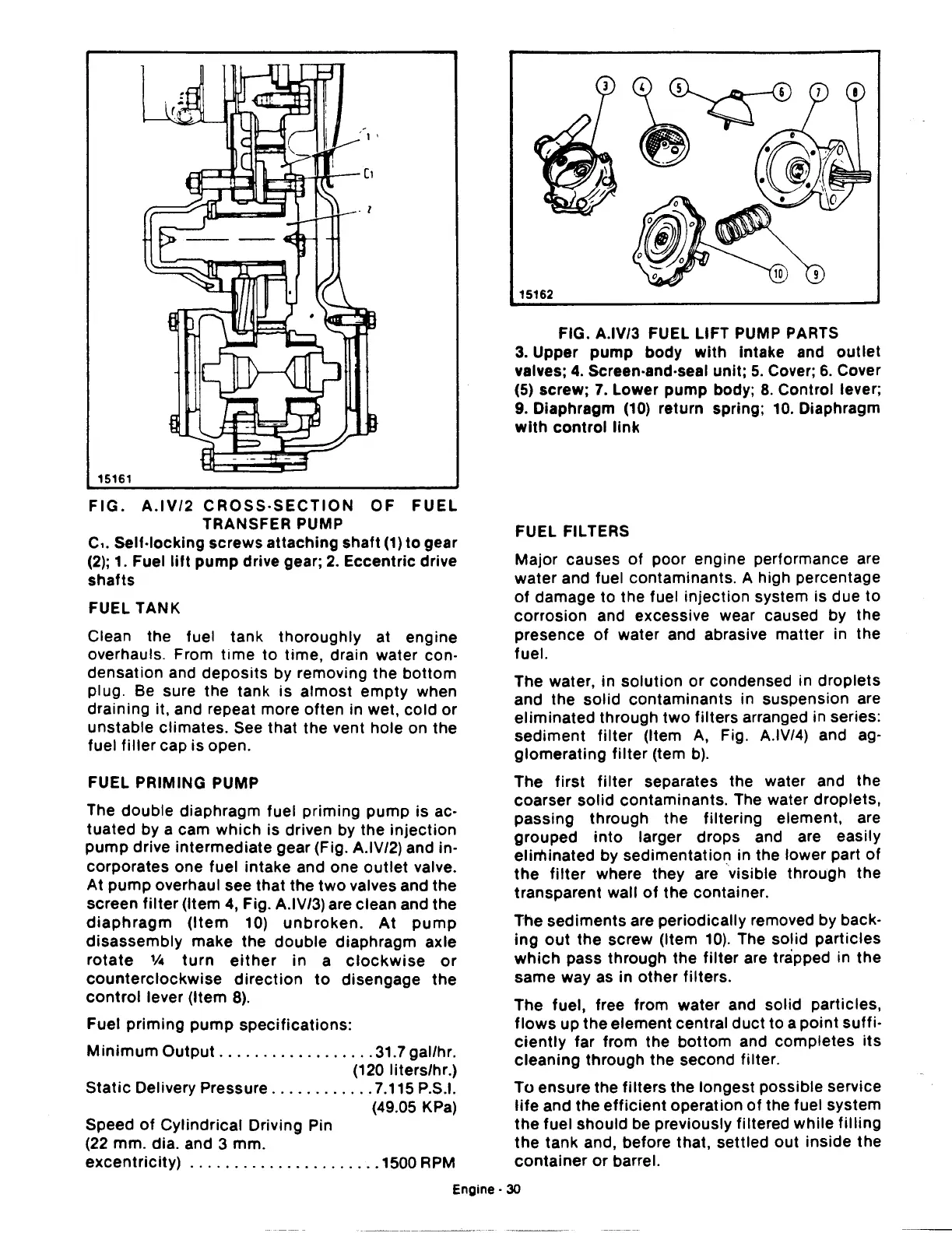

15162

FIG. A.IV/3 FUEL LIFT PUMP PARTS

3.

Upper

pump

body

with

intake and

outlet

valves;

4.

Screen-and-seal unit;

5.

Cover;

6.

Cover

(5)

screw;

7.

Lower pump body;

8.

Control lever;

9.

Diaphragm

(10)

return spring;

10.

Diaphragm

with

control

link

FUEL FILTERS

Major causes

of

poor engine performance are

water and fuel contaminants. A high percentage

of

damage to the fuel injection system is due

to

corrosion and excessive wear caused by the

presence

of

water and abrasive matter in the

fuel.

The water, in

solution

or condensed in

droplets

and

the

solid

contaminants in suspension are

eliminated

through

two

filters arranged in series:

sediment

filter

(Item

A,

Fig. A.IV/4) and ag-

glomerating

filter

(tem

b).

The first

filter

separates the water and the

coarser solid contaminants. The water droplets,

passing through the filtering element, are

grouped

into

larger drops and are easily

eliminated

by sedimentation in the lower part

of

the

filter

where they are visible through the

transparent wall

of

the

container.

The sediments are periodically removed by back·

ing

out

the

screw (Item

10).

The solid particles

which

pass through the

filter

are trapped in

the

same way as in

other

filters.

The fuel, free from water and solid particles,

flows

up

the

element central

duct

to

a

point

suffi·

ciently

far from the

bottom

and completes

its

cleaning through the second filter.

To ensure the

filters

the longest possible service

life

and the

efficient

operation

of

the fuel system

the

fuel should be previously filtered while

filling

the

tank and, before that, settled

out

inside

the

container

or

barrel.

Engine·

30

Loading...

Loading...