Specifications:

Fluid

type

...........•...............•.........•.............

Exxon Torque Fluid

56

or

Equivalent

Fluid

capacity

of

transmission case

with

level reaching the upper

dipstick

mark

........

17

Qts. (161itres)

Available fluid for remote ram control

...........................................

10.6 Qts.

(10

lit

res)

Plessey gear type hydraulic pump

...................................................

Model

PO

10

Borg Warner gear type hydraulic pump

..................................................

Optional

Engine/pump speed ratio

................................................................

1:0.91

Pump speed (with engine running at 2400 RPM)

.........................................

2180

RPM

Corresponding

output

with

an

oil temperature

of

122• • 140•F.

(so•-so•c.)

and

2133

PSI

(14707

kPa) pressure at 2400 engine

RPM

.......................

5.75

GPM

(21.81itres/min.)

(Optional)

10

GPM

(37.8

litres/min.)

Pressure relief valve

setting

.......................................

2062·2204

PSI

(14217-15203

kPa)

Single-acting ram:

Bore and stroke

....................................................

3.54 x 3.54 in.

(90

x

90

mm)

Capacity

.................................................................

34.8 cu. in.

(570

cc)

Cylinder Safety valve pressure

setting

............................

2845-2987

PSI

(19616·20595 kPa)

Nominal

lifting

capacity

................................................

6075 ft.-lb.

(8236

N •

m)

Three-point linkage:

Maximum liftable weight at implement

mounting

points

with

lift

rods

connected

to

lower links

as

follows:

(Figure

17)

in holes

(a)

.....................................................

2645

lb. (1200 kg)

(Figure

17)

in holes

(b)

.....................................................

22051b. (1000 kg)

Lift

arms range

with

lift

rods connected

to

lower links as follows:

(Figure

17)

in holes

(a)

.....................................................

21.6 in.

(550

mm)

(Figure

17)

in holes

(b)

.....................................................

27.2

in.

(690

mm)

Lifting

time

with engine running at 2550

RPM

.............................................

1.5

sec.

Total weight

of

the hydraulic

lift

and linkage

........................................

2291b.

(104

kg)

55361

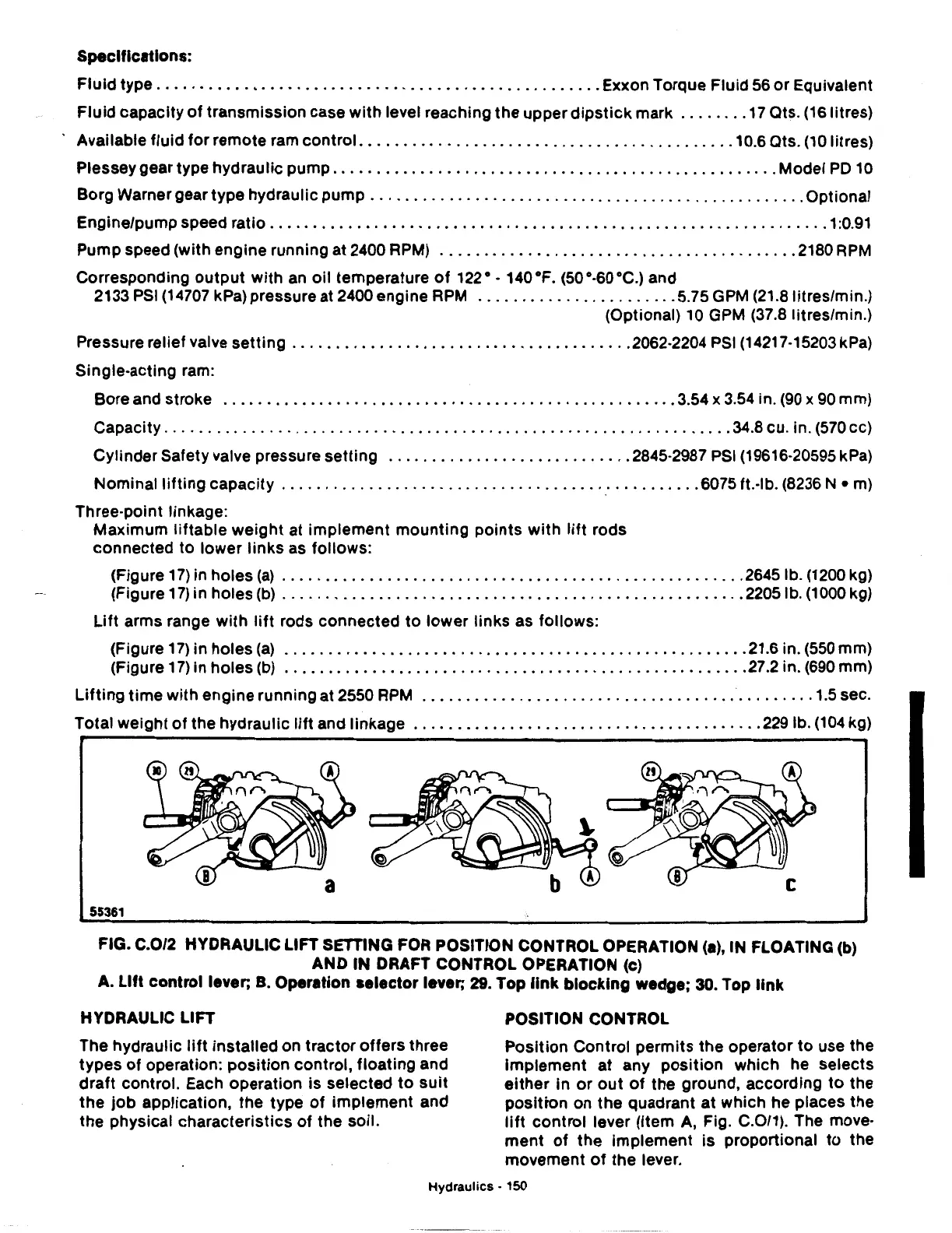

FIG. C.0/2 HYDRAULIC LIFT SETTING FOR POSITION CONTROL OPERATION

(a),

IN FLOATING (b)

AND IN DRAFT CONTROL OPERATION (c)

A.

Lift control lever; B. Operation

selector

lever;

29.

Top

link

blocking

wedge; 30. Top

link

HYDRAULIC LIFT

The hydraulic

lift

installed on tractor offers three

types

of

operation: position control, floating and

draft

control. Each operation is selected

to

suit

the

job

application, the type

of

implement and

the physical characteristics

of

the soil.

POSITION CONTROL

Position Control permits the operator

to

use the

Implement at any position which he selects

either

In

or

out

of

the ground, according

to

the

positron on the quadrant

at

which he places the

lift

control lever (Item

A,

Fig. C.0/1). The move-

ment

of

the Implement is proportional

to

the

movement

of

the lever.

Hydraulics·

150

Loading...

Loading...