DIFFERENTIAL REASSEMBLY

PINION SUPPORT

1.

Press bearing cone (Item

15,

Fig. B.X/12) on

to

pinion

shaft (Item

14),

tapered side out,

and seat

tightly

against

pinion

shoulder.

2.

Place spacer (Item

3)

and shim (Item

12)

onto

pinion shaft next

to

bearing inner race. The

spacer and shim

control

bearing adjustment.

3.

Press inner bearing cup

into

pinion

support

(Item

13),

taper outward. Invert support and

locate outer bearing cup (taper outward)

against inner shoulder. Install outer bearing

cone (Item

5),

new lip seal,

lip

in, (Item

11)

and

dust

cover (Item

10).

4.

Insert bevel

pinion

shaft

into

pinion support.

Install flange (Item

7),

washer (Item

9)

and

nut

(Item

8).

Tighten the nut

to

181

ft.-lbs. (245.4

N-m) torque. Wind a cord

(5·6

turns) around

the drive sleeve and using a pull scale on the

cord, check the rolling torque

of

the

pinion

shaft. This torque must be 4.2

to

8.4 in.-lbs.

(0.47-0.95 N·m). The scale reading should be

3.96

to 7.93 lbs. (17.6·35.3

N).

Do

not

read

the

starting torque. If the scale reading is less

than the above figure, reduce the shim stack.

If higher, add shims.

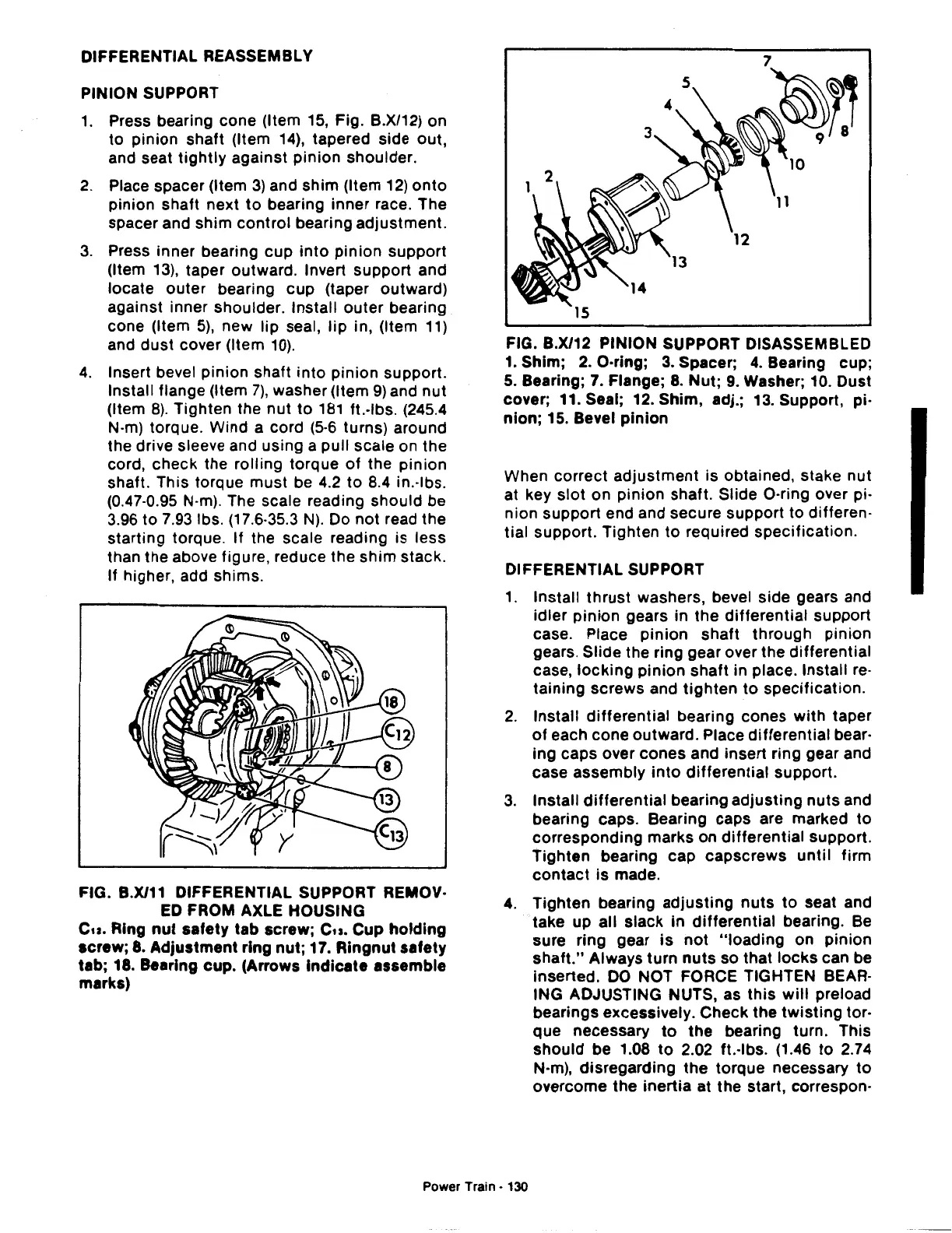

FIG. B.X/11 DIFFERENTIAL SUPPORT REMOV·

ED

FROM AXLE HOUSING

Cu.

Ring

nut

safety tab screw;

Cu.

Cup

holding

screw; 8.

Adjustment

ring nut; 17. Ringnut safety

tab; 18. Bearing cup. (Arrows Indicate assemble

marks)

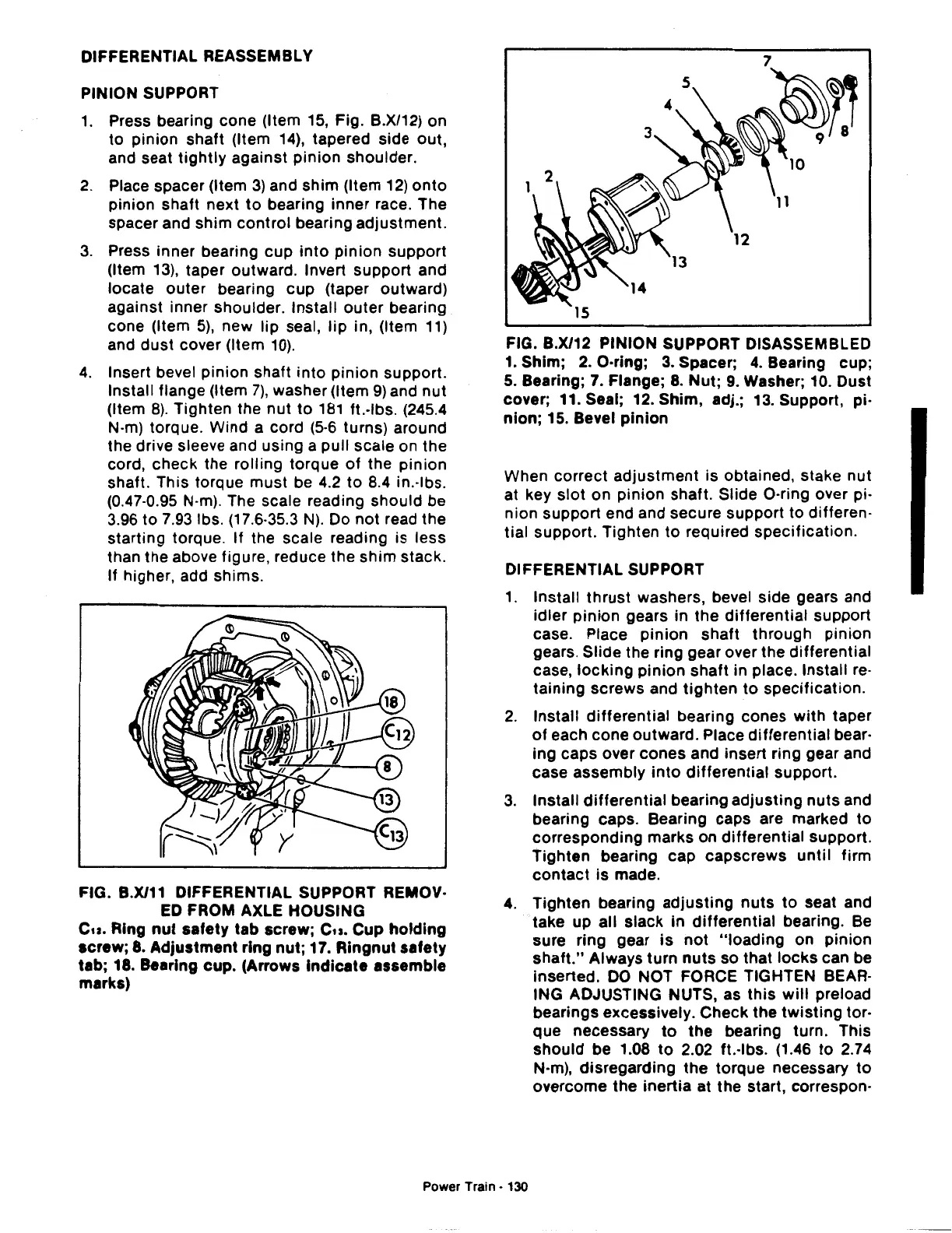

FIG. B.X/12 PINION SUPPORT DISASSEMBLED

1.

Shim;

2.

O·ring;

3.

Spacer;

4.

Bearing cup;

5.

Bearing;

7.

Flange;

8.

Nut;

9.

Washer;

10.

Oust

cover; 11. Seal; 12. Shim, adj.; 13. Support, pi·

nion;

15. Bevel

pinion

When correct

adjustment

is obtained, stake nut

at key

slot

on pinion shaft. Slide O·ring over pi·

nion support end and secure support to differen·

tial support. Tighten

to

required specification.

DIFFERENTIAL SUPPORT

1.

Install

thrust

washers, bevel side gears and

idler

pinion

gears in the differential support

case. Place

pinion

shaft through pinion

gears. Slide the ring gear over the differential

case,

locking

pinion

shaft in place. Install re·

taining screws and

tighten

to

specification.

2.

Install

differential

bearing cones

with

taper

of

each cone outward. Place differential bear·

ing caps over cones and insert ring gear and

case assembly

into

differential

support.

3.

Install

differential

bearing adjusting

nuts

and

bearing caps. Bearing caps are marked

to

corresponding marks on differential support.

Tighten bearing cap capscrews

until

firm

contact

is

made.

4.

Tighten bearing

adjusting

nuts

to

seat and

take up all slack in

differential

bearing. Be

sure ring gear

is

not

"loading

on

pinion

shaft."

Always turn

nuts

so that

locks

can be

inserted.

DO

NOT FORCE TIGHTEN BEAR·

lNG ADJUSTING NUTS, as

this

will

preload

bearings excessively. Check the

twisting

tor-

que necessary

to

the

bearing turn. This

should

be 1.08

to

2.02 ft.-lbs. (1.46

to

2.74

N·m), disregarding

the

torque necessary

to

overcome

the

inertia

at the start, correspon-

Power Train • 130

Loading...

Loading...