1. SETTING THE CONTROL SPRING MOVE·

MENT

The correct

setting

of

the double

acting

control

spring (Item 94, Fig. C.0/19) ensures that the

valve spool

will

not

exceed the present

limits

and

that

the

complete

displacement, subdivided

into

compression

and tension,

is

the desired one. All

this

is

necessary

to

avoid mechanical troubles

such

as

spring

permanent yields

or

rupture or

leverage straining, etc.

Adjust

the

hydraulic

lift

installed on the

tractor

as follows:

1.

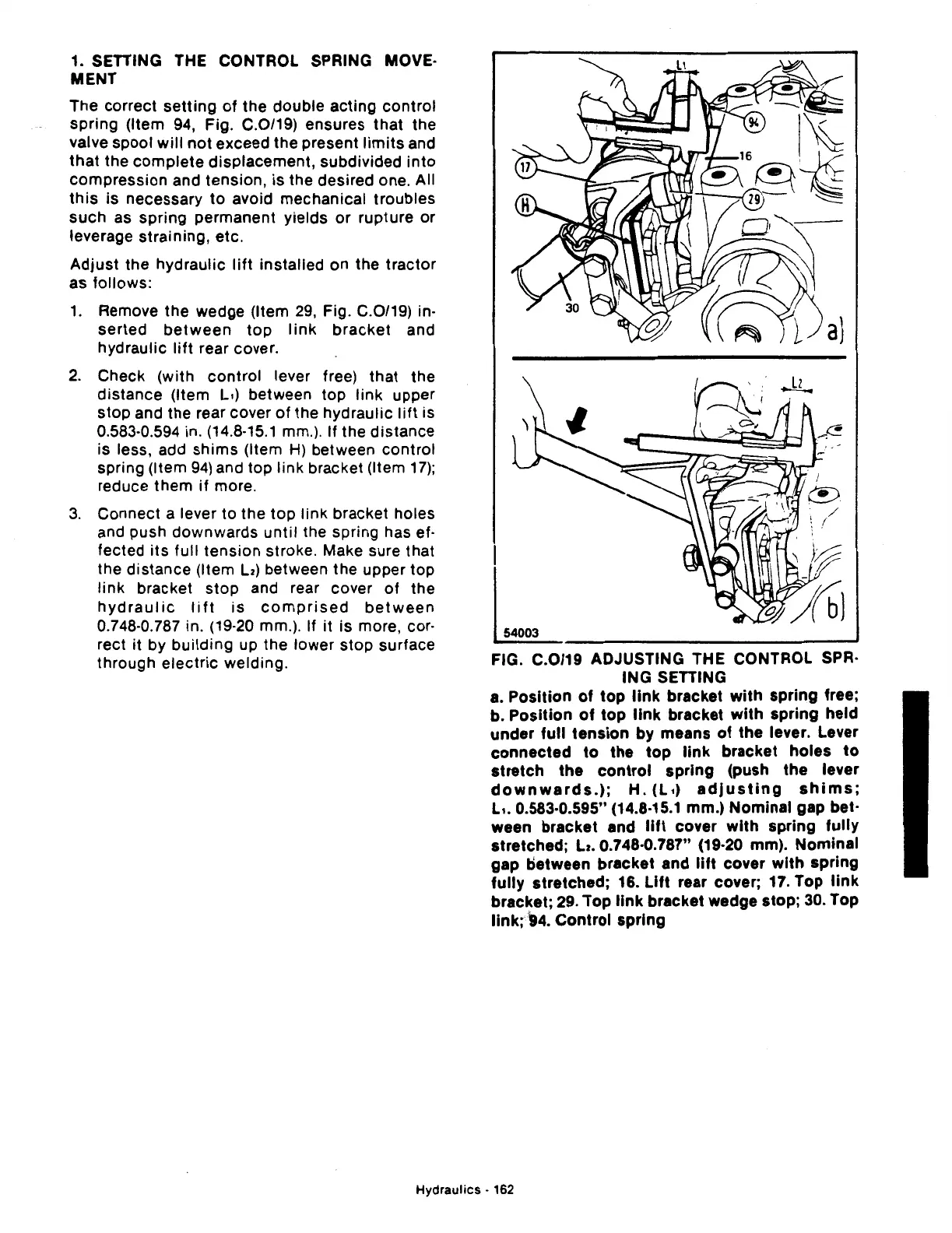

Remove the wedge (Item

29,

Fig. C.0/19) in-

serted

between

top

link

bracket

and

hydraulic

lift

rear cover.

2.

Check (with

control

lever free) that the

distance (Item L,) between top

link

upper

stop

and the rear cover

of

the hydraulic

lift

is

0.583-0.594 in. (14.8-15.1 mm.). If the distance

is less, add

shims

(Item

H)

between control

spring (Item

94)

and top

link

bracket (Item

17);

reduce them

if

more.

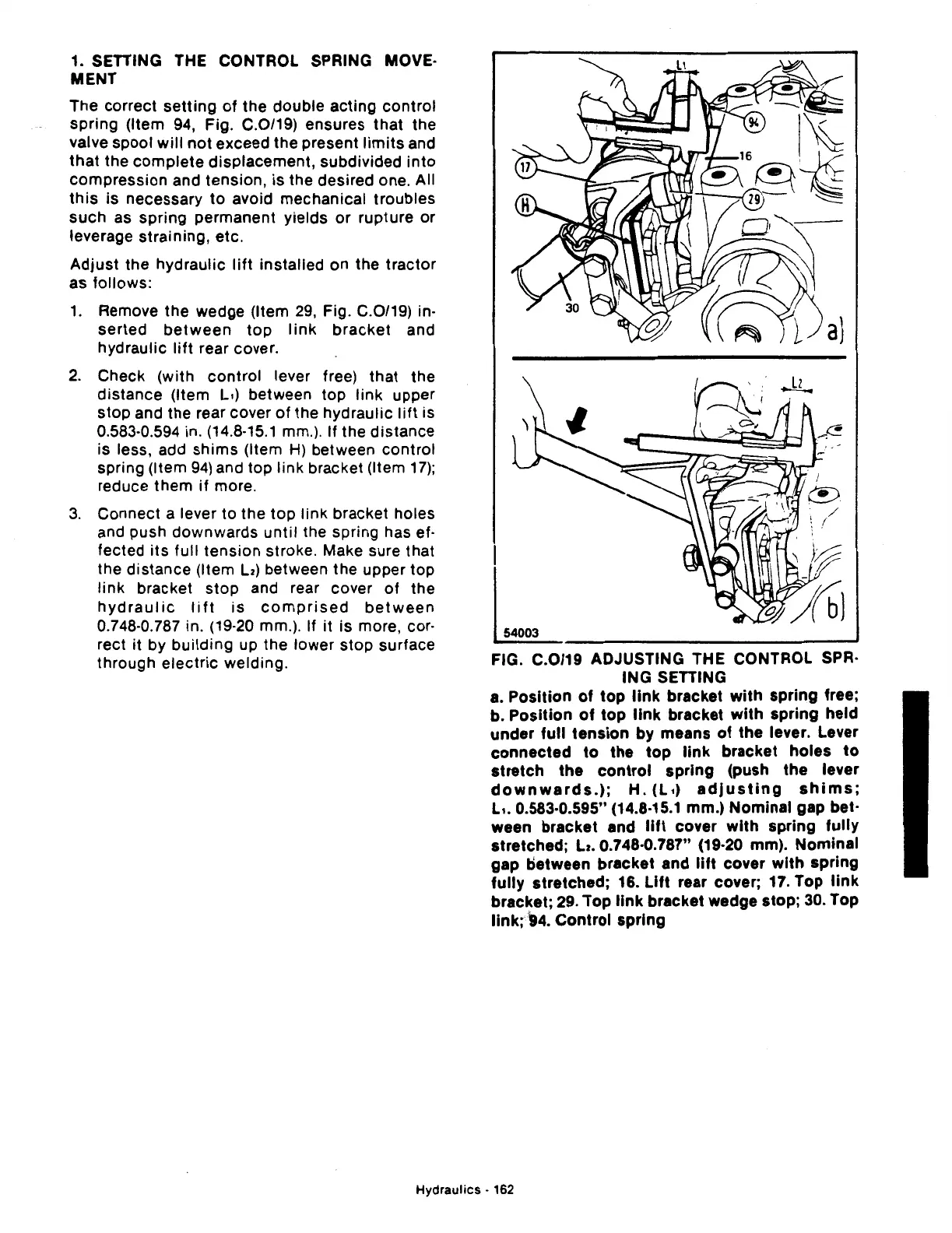

3.

Connect a lever

to

the

top

link

bracket holes

and push downwards

until

the spring has ef·

fected

its

full tension stroke. Make sure that

the distance (Item

l2)

between the upper top

link

bracket

stop

and rear cover

of

the

hydraulic

lift

is

comprised

between

0.748-0.787 in. (19-20 mm.). If it is more, cor-

rect it by

building

up the lower

stop

surface

through

electric

welding.

~------------~

FIG. C.0/19 ADJUSTING THE CONTROL SPR·

lNG

SETTING

a.

Position

of

top

link

bracket

with

spring

free;

b.

Position

of

top

link

bracket

with

spring

held

under

full

tension

by means

of

the lever. Lever

connected

to

the

top

link

bracket

holes

to

stretch

the

control

spring

(push the lever

downwards.);

H.

(L,)

adjusting

shims;

L,. 0.583·0.595" (14.8·15.1 mm.)

Nominal

gap

bet-

ween bracket and

lift

cover

with

spring

fully

stretched;

Lz.

0.748·0.787" (19·20 mm).

Nominal

gap t)etween bracket and

lift

cover

with

spring

fully

stretched;

16.

Lift

rear cover; 17. Top

link

bracket; 29.

Top

link

bracket wedge stop; 30. Top

link;

94.

Control

spring

Hydraulics

· 162

Loading...

Loading...