14015

9.

Timing Gear Case Cover.

10.

Engine Flywheel (Item

1)

as indicated on

page

28).

11.

Crankshaft rear gasket (Item

8).

12.

Connecting rod and main bearing caps

(Items 4 and

3, respectively).

Wash the crankshaft

with

solvent and inspect it

thoroughly. Damages

of

any kind, however

slight, require that the shaft

be

replaced or

repaired. Examine wear on connecting rod and

main bearing journals and make sure that:

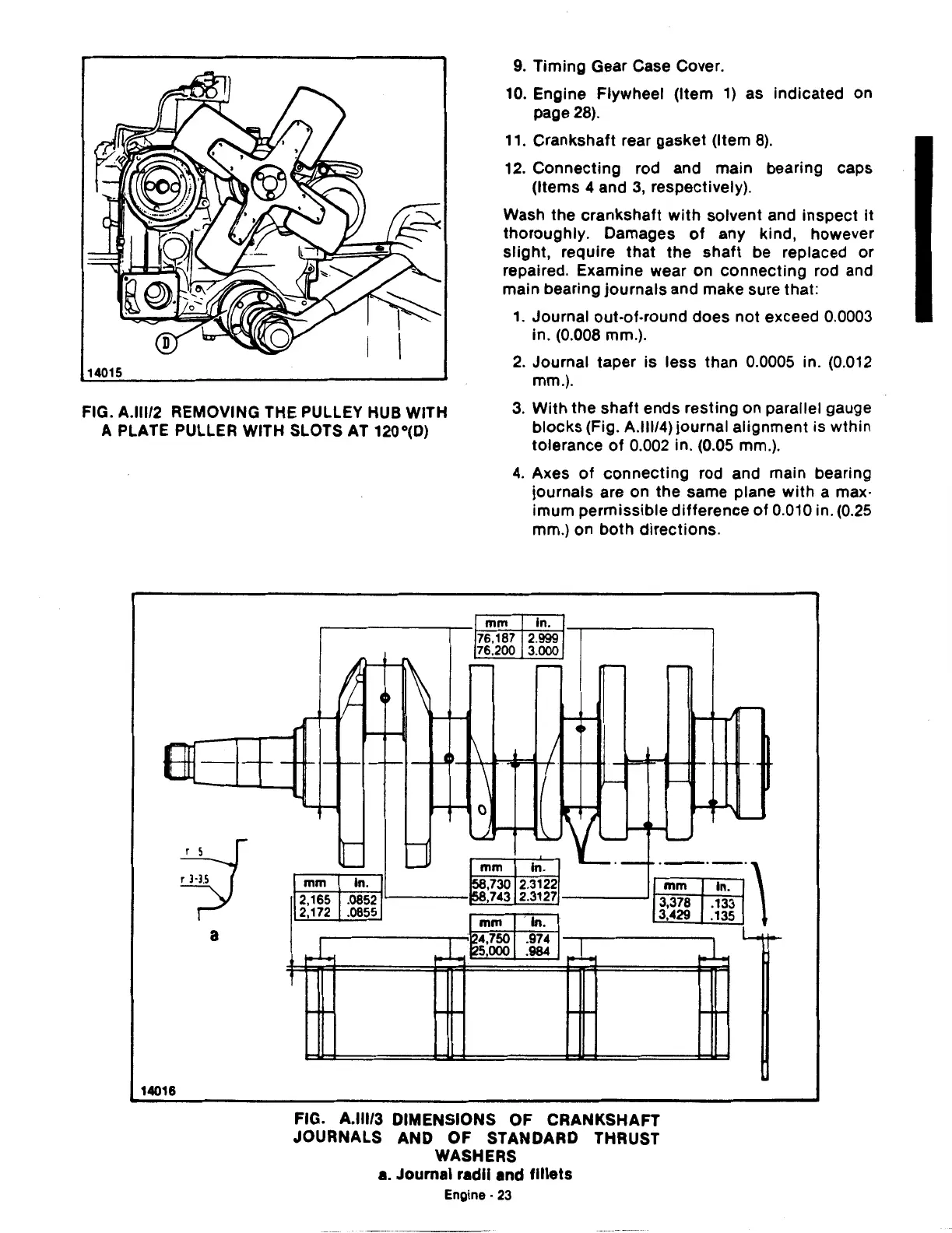

1.

Journal out-of·round does not exceed 0.0003

in. (0.008 mm.).

2.

Journal taper is less than 0.0005 in.

(0.012

mm.).

FIG. A.lll/2 REMOVING THE PULLEY HUB WITH

A PLATE PULLER WITH SLOTS

AT

120°(0)

3.

With the shaft ends resting on parallel gauge

blocks (Fig. A.lll/4) journal alignment is wthin

tolerance

of

0.002 in. (0.05 mm.).

a-

1-

f--

s

;I

a

14016

4.

Axes

of

connecting rod and main bearing

journals are on the same plane with a max·

imum permissible difference

of

0.010 in.

(0.25

mm.) on both directions.

mm I ln.

76,18712.999

76,200 3.000

~~

f--

--

~

-

~

,...._

,...._

c

,...._

,......;

~

'--

-

~

-

1-

1-

~

4

'-

:-

r-

\

L-

I

·-

f-·

\

7

1-- 1--

'-

I-

I-I-

0

r

....

LJ

L.

1--J

L-

l.L.

~

F-

1---.

"---

'--

t

l.....,j

mm

ln.

·-

·-·-·\

mm

ln.

~.730

2.3122

mm ln.

2,165

.0852

,743 2.3127

3,378 .133

2,172 .0855

ln.

3,429 .135

mm

,.1

...1.:~~·750

.974

~

5,000

.984

....

1- 1-

FIG. A.lll/3 DIMENSIONS OF CRANKSHAFT

JOURNALS AND OF STANDARD THRUST

WASHERS

a. Journal radii and

fillets

Engine·

23

:1.

~~--

....

1-

Loading...

Loading...