\

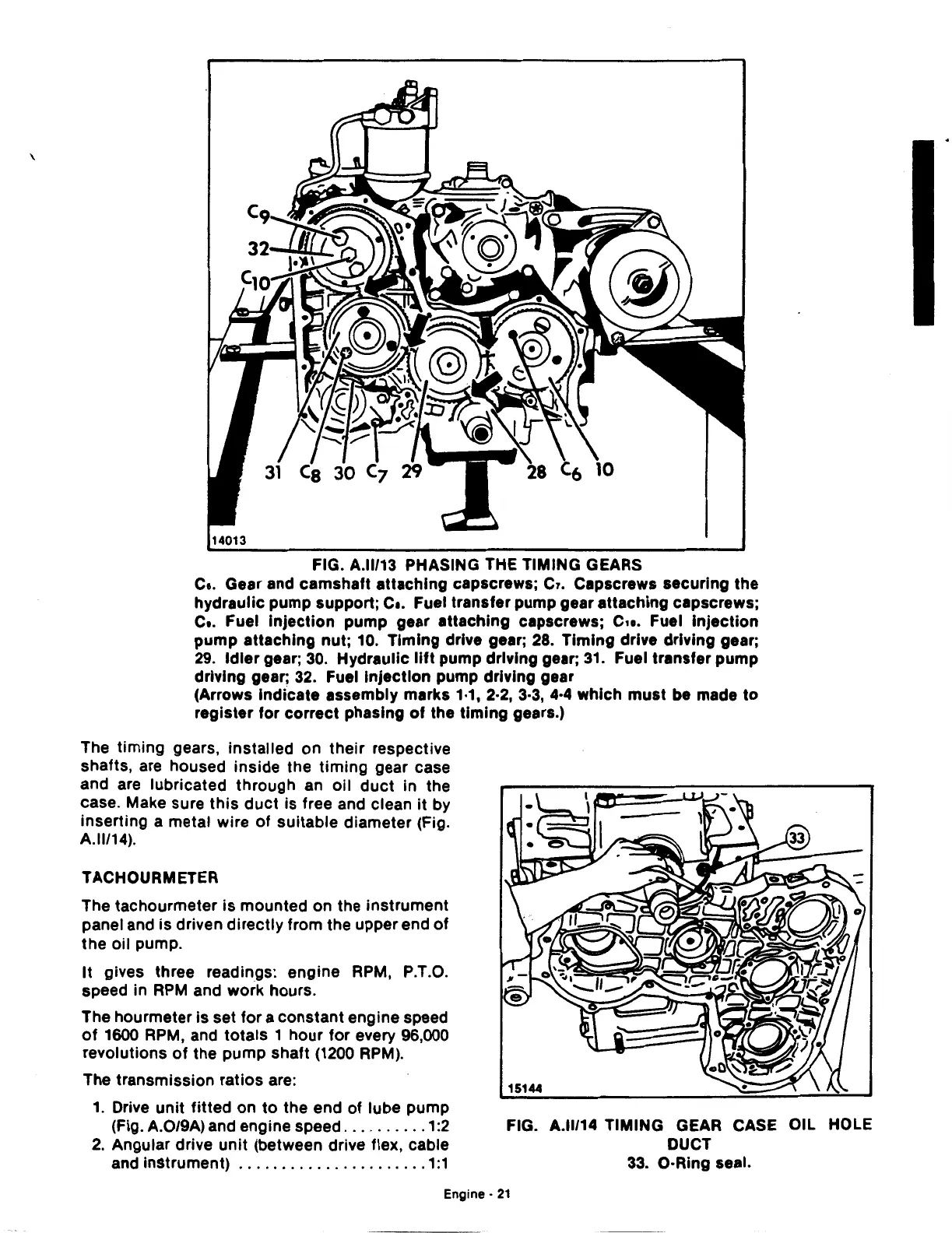

FIG. A.ll/13 PHASING THE TIMING GEARS

c..

Gear and camshaft attaching capscrews; Cr. Capscrews securing the

hydraulic pump support;

c

•.

Fuel transfer pump gear attaching capscrews;

c..

Fuel Injection pump gear attaching capscrews;

c,

•.

Fuel Injection

pump attaching nut; 10. Timing drive gear;

28.

Timing drive driving gear;

29.

Idler gear;

30.

Hydraulic lift pump driving gear;

31.

Fuel transfer pump

driving gear;

32.

Fuel Injection pump driving gear

(Arrows Indicate assembly marks 1·1, 2·2,

3·3,

4·4

which

must

be made

to

register for correct phasing

of

the timing gears.)

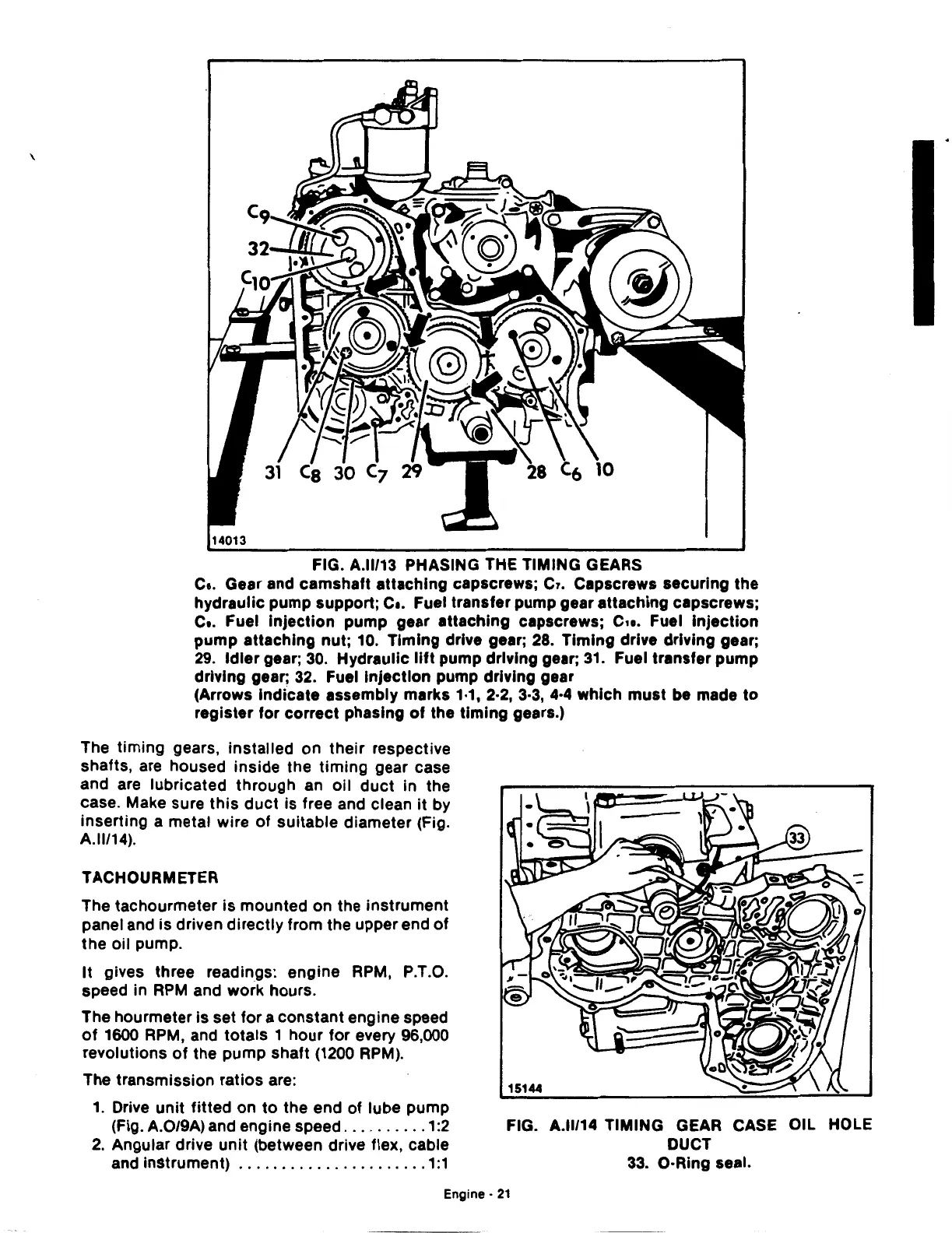

The timing gears, installed on their respective

shafts, are housed inside the

timing

gear case

and are lubricated through an oil

duct

in the

case. Make sure

this

duct

is free and clean

it

by

inserting a metal wire

of

suitable diameter (Fig.

A.ll/14).

TACHOURMETER

The tachourmeter

is

mounted on the instrument

panel and

is

driven directly from the upper end

of

the

oil pump.

It

gives three readings: engine RPM, P.T.O.

speed in

RPM

and work hours.

The hourmeter

is

set for a constant engine speed

of

1600

RPM, and totals 1 hour for every 96,000

revolutions

of

the pump shaft

(1200

RPM).

The transmission ratios are:

1.

Drive unit fitted on

to

the end of lube pump

(Fig. A.0/9A) and engine speed

..........

1:2

2.

Angular drive unit (between drive flex, cable

and instrument)

......................

1:1

FIG. A.ll/14 TIMING GEAR CASE OIL HOLE

DUCT

33.

O·Ring seal.

Engine·

21

Loading...

Loading...