25033

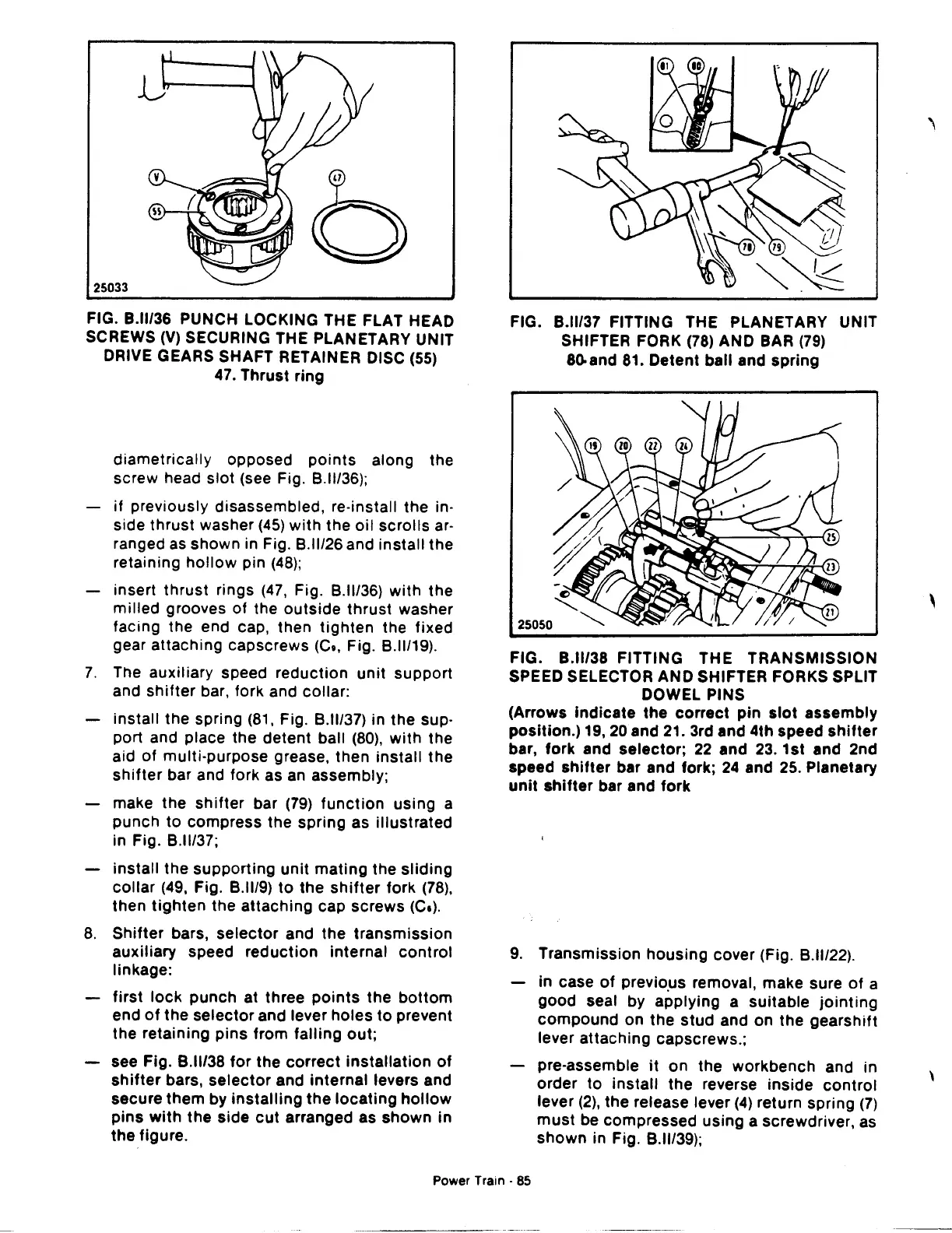

FIG.

8.11/36

PUNCH LOCKING THE FLAT HEAD

SCREWS

(V)

SECURING THE PLANETARY UNIT

DRIVE GEARS SHAFT RETAINER DISC (55)

47.

Thrust ring

diametrically opposed

points

along the

screw head slot (see Fig.

8.11136);

if

previously disassembled, re-install the in-

side thrust washer

(45)

with

the

oil

scrolls

ar-

ranged

as

shown in Fig. B.ll/26 and install the

retaining

hollow

pin

(48);

insert thrust rings

(47,

Fig. B.ll/36)

with

the

milled

grooves of the

outside

thrust

washer

facing the end cap, then

tighten

the fixed

gear attaching capscrews

(Ca, Fig. B.ll/19).

7.

The auxiliary speed reduction

unit

support

and

shifter

bar, fork and collar:

install the spring

(81,

Fig. B.ll/37) in the sup-

port and place the detent ball

(80),

with

the

aid

of

multi-purpose grease, then install

the

shifter

bar and fork as an assembly;

make the

shifter

bar

(79)

function

using a

punch to compress the spring as illustrated

in Fig. B.ll/37;

install the supporting

unit

mating

the

sliding

collar

(49,

Fig. B.ll/9)

to

the

shifter

fork

(78),

then

tighten

the attaching cap screws (Ce).

8.

Shifter

bars,

selector

and the transmission

auxiliary speed reduction internal

control

linkage:

first

lock

punch at three

points

the

bottom

end

of

the selector and lever holes

to

prevent

the retaining pins from falling out;

see Fig. B.ll/38

for

the

correct

installation

of

shifter

bars,

selector

and internal levers and

secure them by

installing

the

locating

hollow

pins

with

the

side

cut

arranged as

shown

in

the

figure.

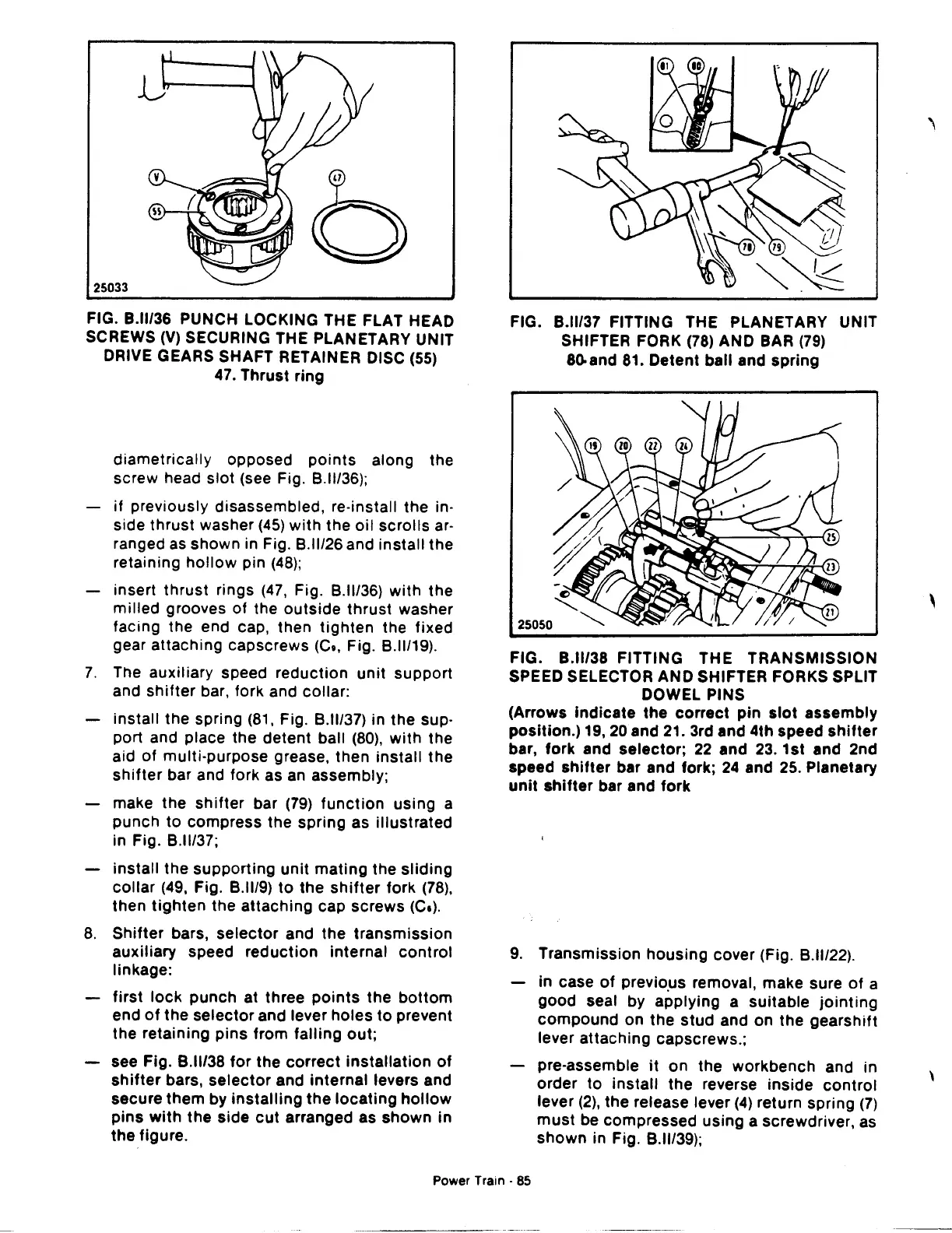

FIG.

8.11137

FITTING THE PLANETARY UNIT

SHIFTER FORK

(78)

AND BAR

(79)

80.and 81. Detent ball and spring

FIG.

8.11/38

FITTING THE TRANSMISSION

SPEED SELECTOR AND SHIFTER FORKS SPLIT

DOWEL PINS

(Arrows Indicate the

correct

pin

slot

assembly

position.) 19,20 and

21.

3rd and 4th speed

shifter

bar, fork and selector;

22

and

23.

1st and 2nd

speed

shifter

bar and fork;

24

and 25. Planetary

unit

shifter

bar and fork

9.

Transmission

housing

cover (Fig. B.ll/22).

in case

of

previo.us removal, make sure

of

a

good seat by applying a suitable

jointing

compound

on the

stud

and on

the

gearshift

lever attaching capscrews.;

pre-assemble

it

on the workbench and in

order to install the reverse inside

control

lever

(2),

the release lever

(4)

return spring

(7)

must

be compressed using a screwdriver, as

shown in Fig.

8.11139);

Power Train · 85

'

\

Loading...

Loading...