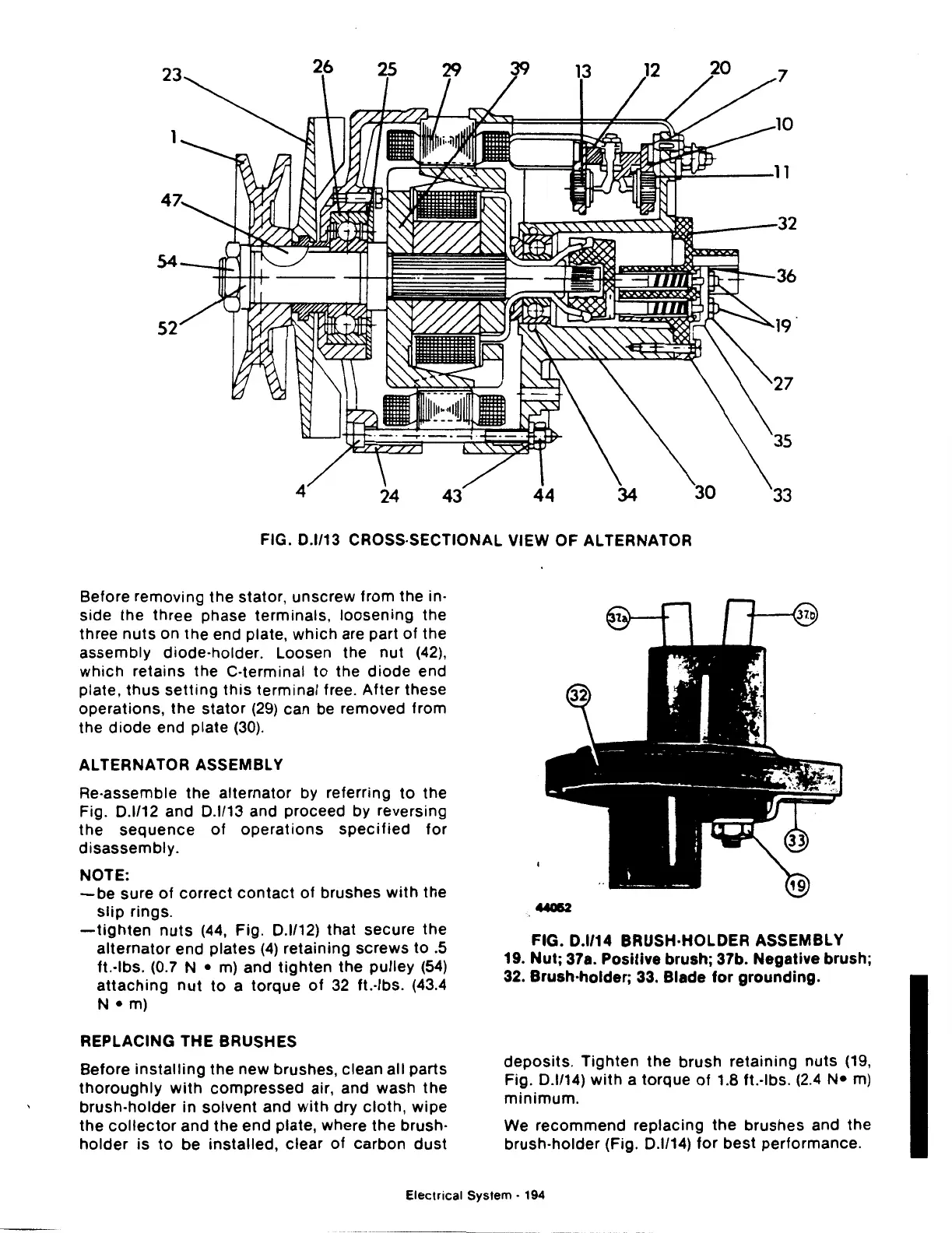

FIG. 0.1/13 CROSS-SECTIONAL VIEW

OF

ALTERNATOR

Before removing the stator, unscrew from the in·

side the three phase terminals, loosening the

three

nuts

on the end plate,

which

are part

of

the

assembly diode-holder. Loosen the

nut

(42),

which

retains the C-terminal

to

the

diode

end

plate,

thus

setting

this

terminal free. After these

operations, the

stator

(29)

can be removed from

the diode end plate

(30).

ALTERNATOR

ASSEMBLY

Re-assemble the alternator by referring

to

the

Fig.

0.1112

and

0.1113

and proceed by reversing

the

sequence

of

operations

specified

for

disassembly.

NOTE:

-be

sure

of

correct

contact

of

brushes

with

the

slip

rings.

-tighten

nuts

(44, Fig.

0.1112)

that secure

the

alternator

end plates

(4)

retaining screws

to

.5

ft.·lbs. (0.7 N • m) and

tighten

the

pulley

(54)

attaching

nut

to

a torque

of

32 ft.·lbs. (43.4

N •

m)

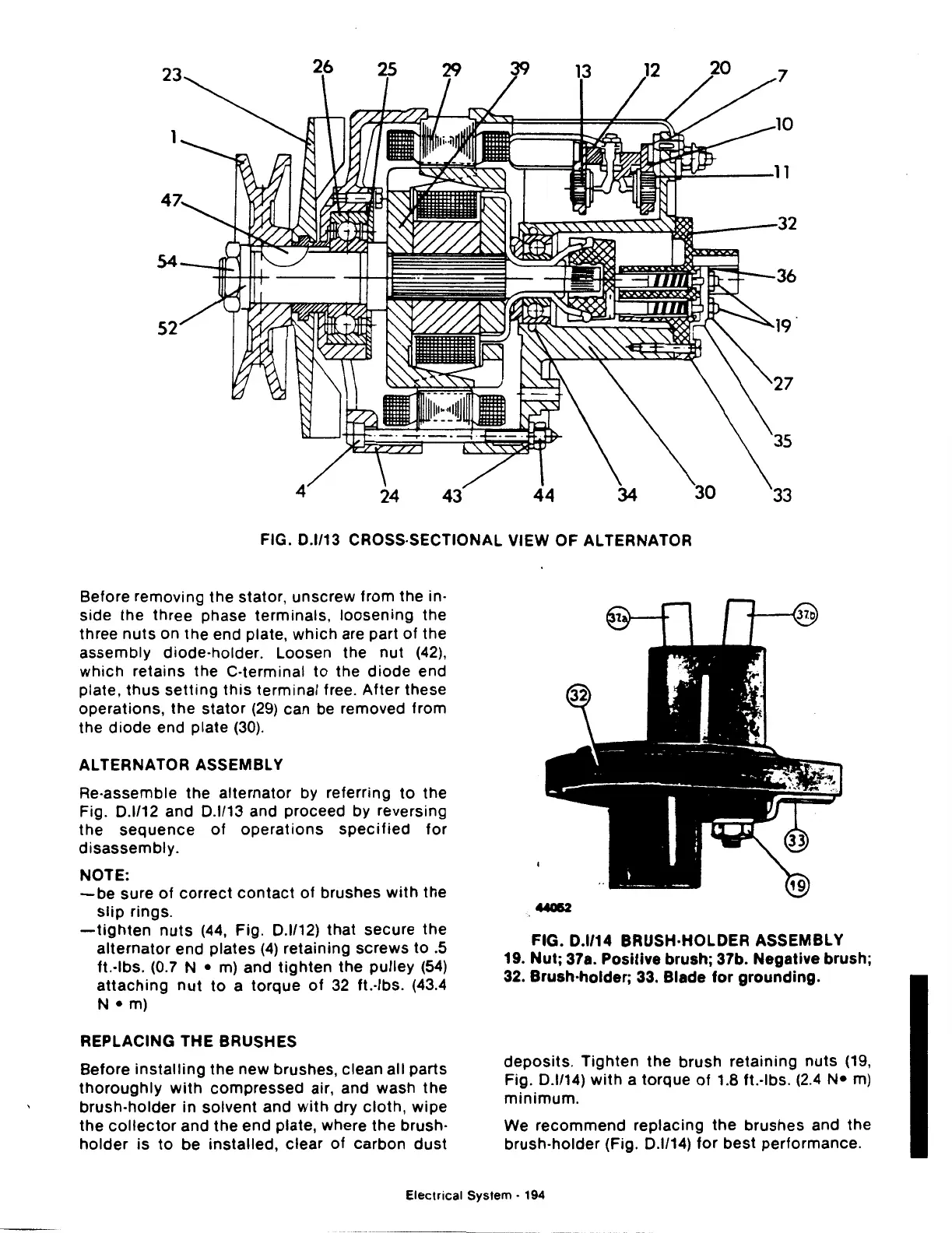

REPLACING

THE

BRUSHES

Before

installing

the new brushes, clean all parts

thoroughly

with

compressed air, and wash

the

brush-holder in solvent and

with

dry

cloth,

wipe

the

collector

and the end plate, where the brush·

holder

is

to

be installed, clear

of

carbon

dust

FIG. 0.1/14 BRUSH-HOLDER ASSEMBLY

19. Nut; 37a. Positive brush; 37b. Negative brush;

32.

Brush-holder; 33. Blade

for

grounding.

deposits.

Tighten

the

brush retaining

nuts

(19,

Fig.

0.1114)

with

a torque

of

1.8 ft.·lbs. (2.4

N•

m)

minimum.

We recommend replacing

the

brushes and the

brush-holder (Fig.

0.1114)

for

best performance.

Electrical

System·

194

Loading...

Loading...