rotating the armature slowly. The ammeter will in-

dicate the

flow

of

a current, which

will

attain a

given magnitude at a certain distance

of

the blade

coupler

with

respect

to

the starting position. By

repeating

this

operation for each successive pair

of

bars, the ammeter reading, always in the chosen

position, shall always be the same.

No

flow

of

cur-

rent will be shown by the ammeter

if

the circuit is

interrupted. Should the ammeter readings differ,

the

cause may be shorts in the winding zones; in

this

case repeat at the shorting test

the

operations

indicated in the preceding paragraph.

~

..

• • •

~

-~

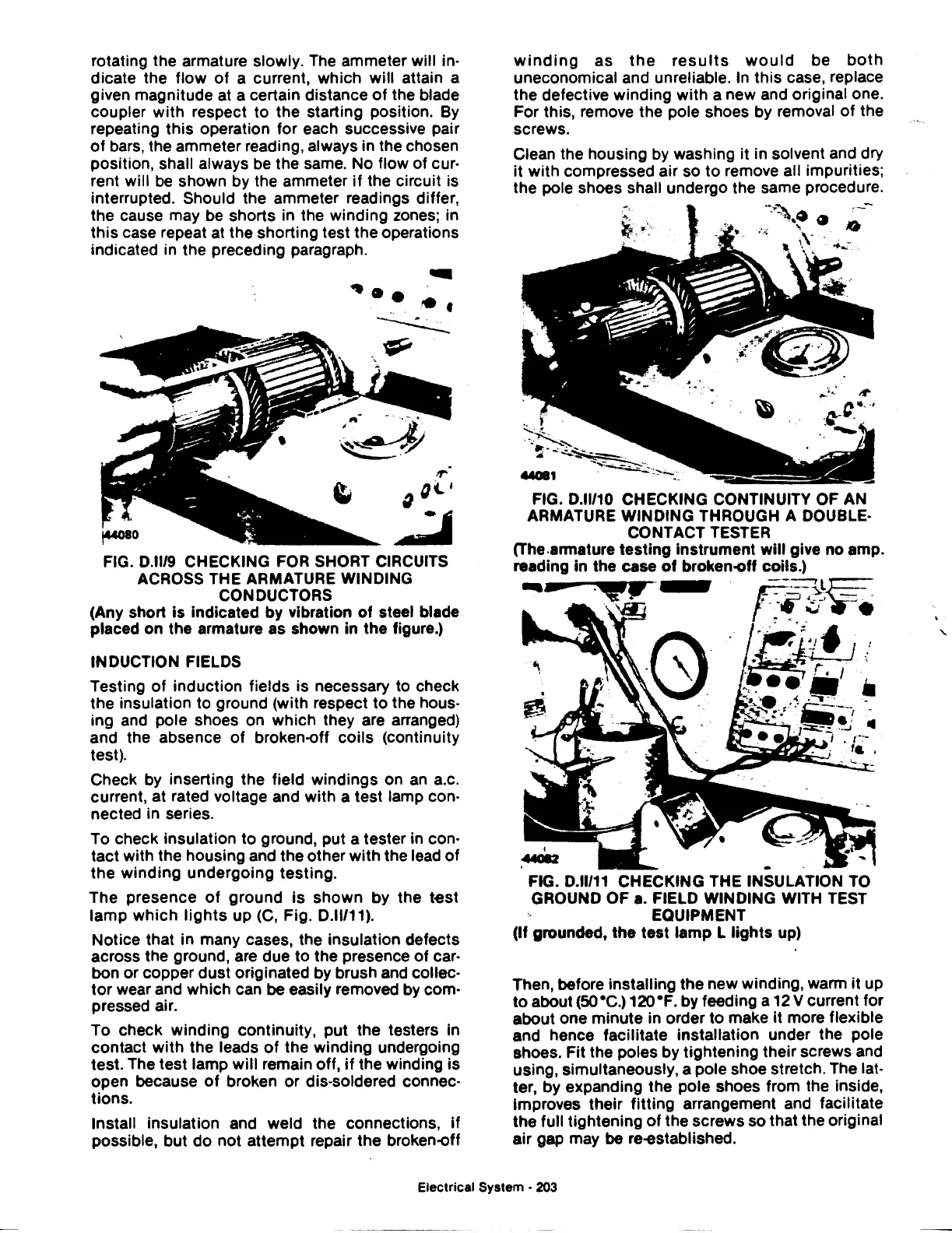

FIG. D.lll9 CHECKING FOR SHORT CIRCUITS

ACROSS THE ARMATURE WINDING

CONDUCTORS

(Any short

is

Indicated

by

vibration

of

steel blade

placed on the armature as shown in the figure.)

INDUCTION FIELDS

Testing

of

induction fields is necessary

to

check

the

insulation

to

ground (with respect

to

the hous-

ing and pole shoes on

which

they are arranged)

and the absence

of

broken-off

coils

(continuity

test).

Check by inserting the field windings on

an

a.c.

current, at rated voltage and with a test lamp con-

nected in series.

To check insulation

to

ground, put a tester in con-

tact with

the

housing and

the

other

with

the lead

of

the

winding

undergoing

testing.

The

presence

of

ground

is

shown

by

the

t~st

lamp

which

lights

up

(C, Fig.

0.11111).

Notice

that in many cases, the insulation defects

across the ground, are due

to

the presence

of

car-

bon

or

copper

dust

originated by brush and collec-

tor

wear and

which

can be easily removed by com-

pressed air.

To

check winding continuity,

put

the

testers In

contact

with

the leads

of

the winding undergoing

test. The test lamp

will

remain off,

if

the winding

is

open because

of

broken

or

dis-soldered connec-

tions.

Install insulation and weld the connections,

if

possible, but

do

not

attempt

repair

the

broken-off

winding

as

the

results

would

be

both

uneconomical and unreliable. In

this

case, replace

the

defective winding

with

a new and original one.

For this, remove the pole shoes by removal

of

the

screws.

Clean the housing by washing it in solvent and dry

it

with

compressed

air

so

to

remove all impurities;

the

pole shoes shall undergo the same procedure.

~.

·-.~~,~

~

,--

:-;

\·

....

._

..

44011

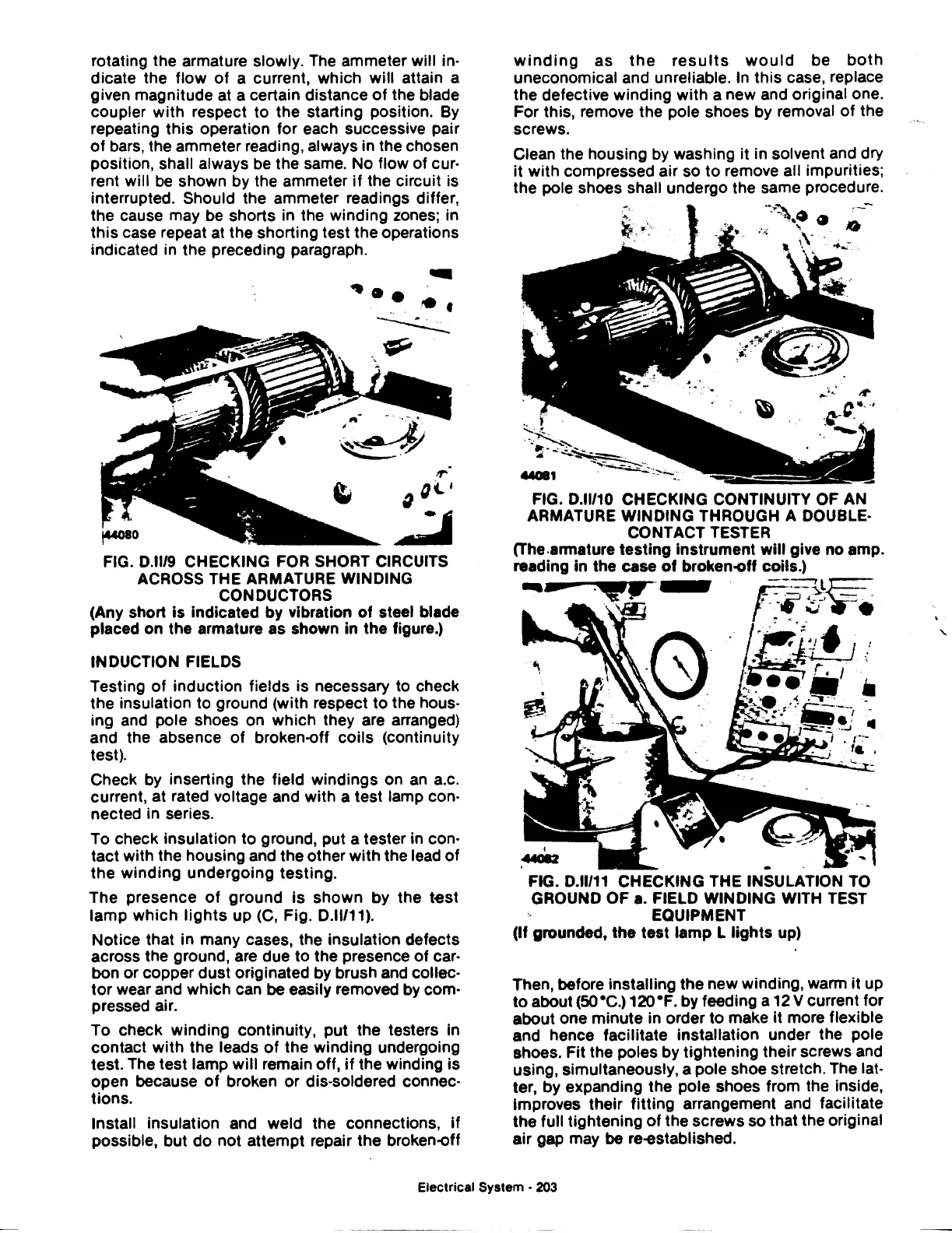

FIG. D.lll10 CHECKING CONTINUITY OF AN

ARMATURE WINDING THROUGH A DOUBLE·

CONTACT TESTER

(The .armature

testing

instrument

will

give

no

amp.

reading

in

the case

of

broken-off coils.)

-

ii?

~-

- -

--:---,.l~

._..

~-'

-.

I

-44CIIZ

FIG. D.ll/11 CHECKING THE INSULATION TO

GROUND

OF

a.

FIELD WINDING WITH TEST

EQUIPMENT

(If

grounded,

the

test

lamp

L

lights

up)

Then, before installing

the

new

winding, warm

it

up

to

about

(SO•C.)

120•F.

by

feeding a 12 V current for

about one

minute

in order

to

make

it

more flexible

and hence facilitate installation under the pole

shoes.

Fit

the poles by tightening their screws and

using, simultaneously, a pole shoe stretch. The lat-

ter, by expanding the pole shoes from the inside,

Improves their

fitting

arrangement and facilitate

the

full tightening

of

the screws so that the original

air

gap may be re-established.

Electrical System -

203

Loading...

Loading...