5.

Cup shaped

plugs

(Item T, Fig. A.lll/4) seal

properly (test

with

oil

at 213

PSI

[15 kg/cm

2

]).

Should

the

test

show

defective

or

unreliable

sealing tightness, replace

the

plugs

and

repeat the

test

with

new

plugs

installed. If

necessary, grind all crankshaft journals

to

one

of

the undersizes

specified

in

"Fits

and

Tolerances" table. Make sure,

after

grinding,

to machine proper radii and

fillets

on jour-

nals and

to

chamfer the

lubrication

holes.

FRONT END SEAL INSTALLATION

Fluid

tightness

at

front

end

of

crankshaft is en-

sured by a rubber seal

with

coil

spring

which

is

force

fitted

in

the

timing

gear case cover. The

fundamental feature

of

this

seal

is

the spiral

rifling

of

the

sealing

lip

in the

direction

opposite

to

that

of

rotation

of

the

hub.

This

will

throw back

inside any

amount

of

fluid

which

the

hub

would

eventually tend

to

convey outside.

In case

of

oil leakage,

excluding

the

running-in

period during which parts may require adjust-

ment

of

their

final

position

of

assembly, remove

the

pulley hub (Fig. A.0/9A) and check:

1.

The working surface

of

the

seal for wear,

breakage

of

the

rifling

coil

or

of

the sealing

lip.

2.

The sealing surface in

contact

with

the

crankshaft

for

roughness or out-of-round ex-

ceeding 0.012 in. (0.3 mm.).

The seal cover

must

be removed

first

If

the

seal

is

to

be replaced. Take good

note

of

the

follow-

ing

points

to

avoid assembly trouble.

1.

Wipe

off

all traces

of

oil

and

dry

the

seal seat

In

the

cover thoroughly.

2.

Fit

the

seal In

its

seat

without

using

lubricants and apply a

uniform

pressure over

the

entire

seal ring by means

of

a seal In-

staller

so

that

the

seal

will

bottom

in

Its

seat.

3.

Lubricate

the

seal

lip

with

a

film

of

grease

or

thick

oil

to

avoid dry

contact

with

the

crankshaft surface at

the

start,

then

secure

the cover and

its

gasket

to

the

crankcase.

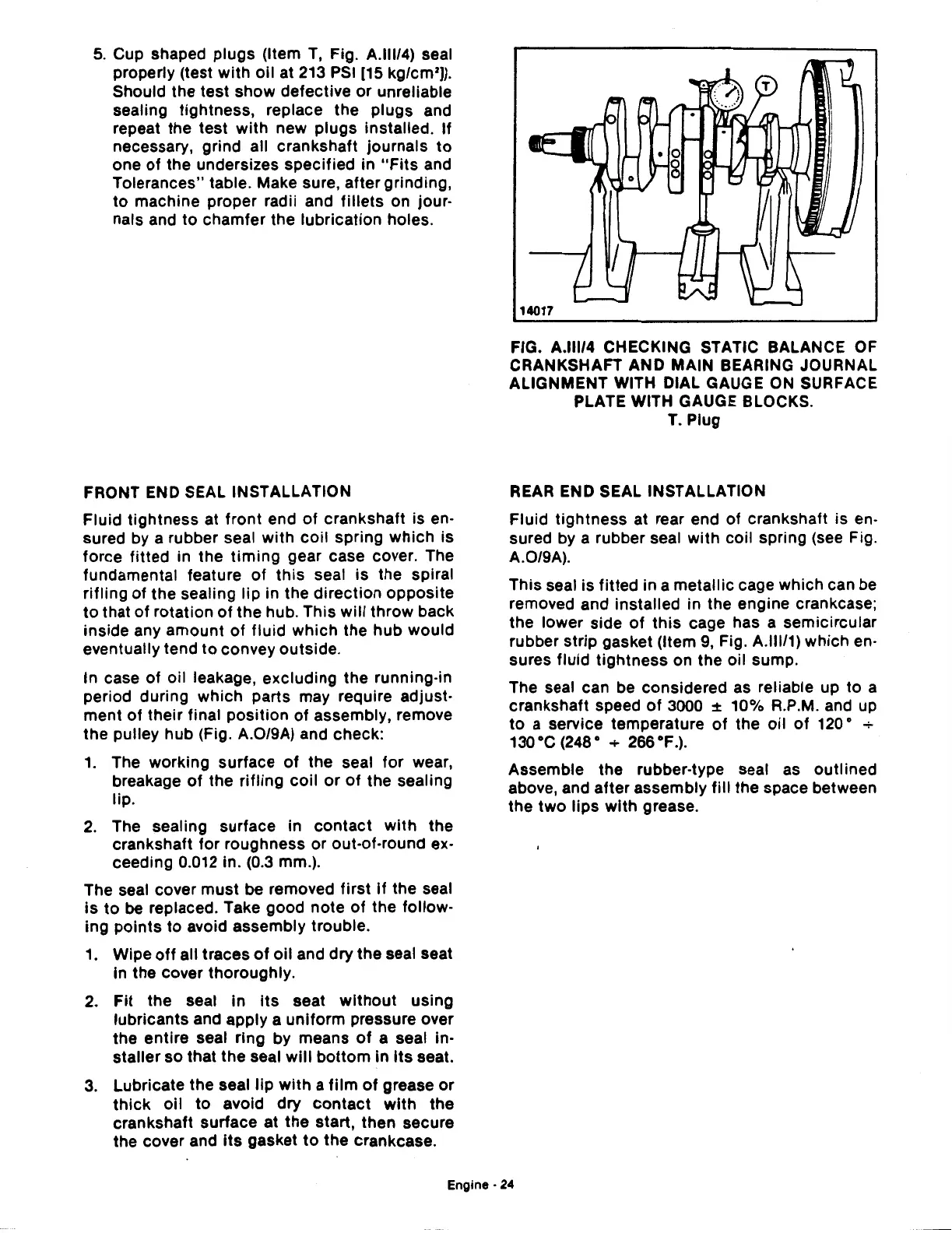

FIG. A.lll/4 CHECKING STATIC BALANCE

OF

CRANKSHAFT AND MAIN BEARING JOURNAL

ALIGNMENT WITH DIAL GAUGE

ON

SURFACE

PLATE WITH GAUGE BLOCKS.

T. Plug

REAR

END SEAL INSTALLATION

Fluid

tightness

at rear end

of

crankshaft is en-

sured by a rubber seal

with

coil spring (see Fig.

A.0/9A).

This seal is

fitted

in a

metallic

cage which can be

removed and installed in the engine crankcase;

the

lower

side

of

this

cage has a semicircular

rubber

strip

gasket (Item 9, Fig. A.lll/1) which en-

sures

fluid

tightness

on

the

oil sump.

The seal

can be considered as reliable up

to

a

crankshaft speed

of

3000

::1:

10% R.P.M. and up

to

a service temperature

of

the

oil

of

120 • +

130 ·c (248 • + 266 ·F.).

Assemble

the

rubber-type seal as

outlined

above, and

after

assembly

fill

the

space between

the

two

lips

with

grease.

Engine-

24

Loading...

Loading...