55373

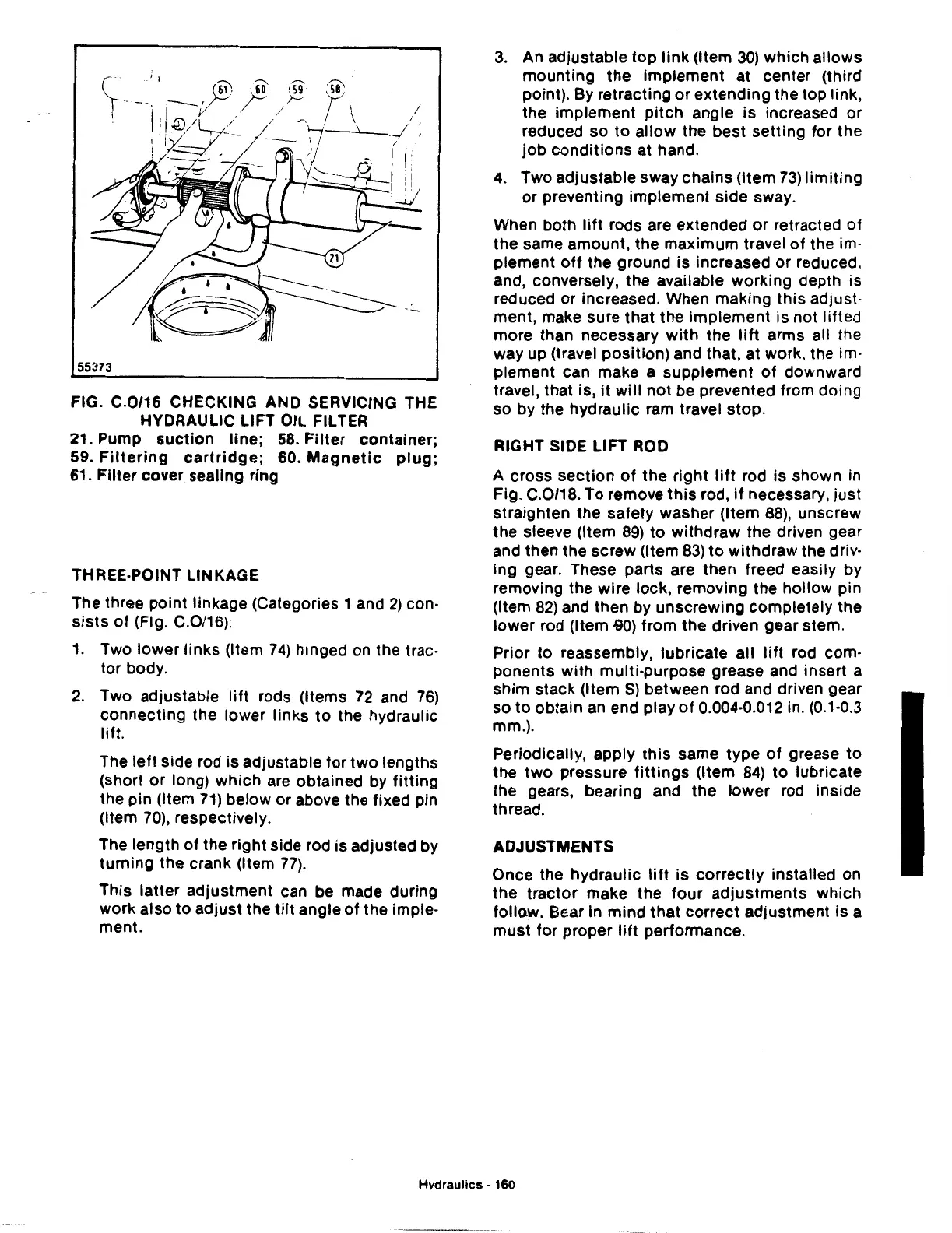

FIG. C.0/16 CHECKING AND SERVICING THE

HYDRAULIC LIFT OIL FILTER

21. Pump

suction

line;

58.

Filter

container;

59.

Filtering

cartridge;

60.

Magnetic

plug;

61. Filter cover sealing ring

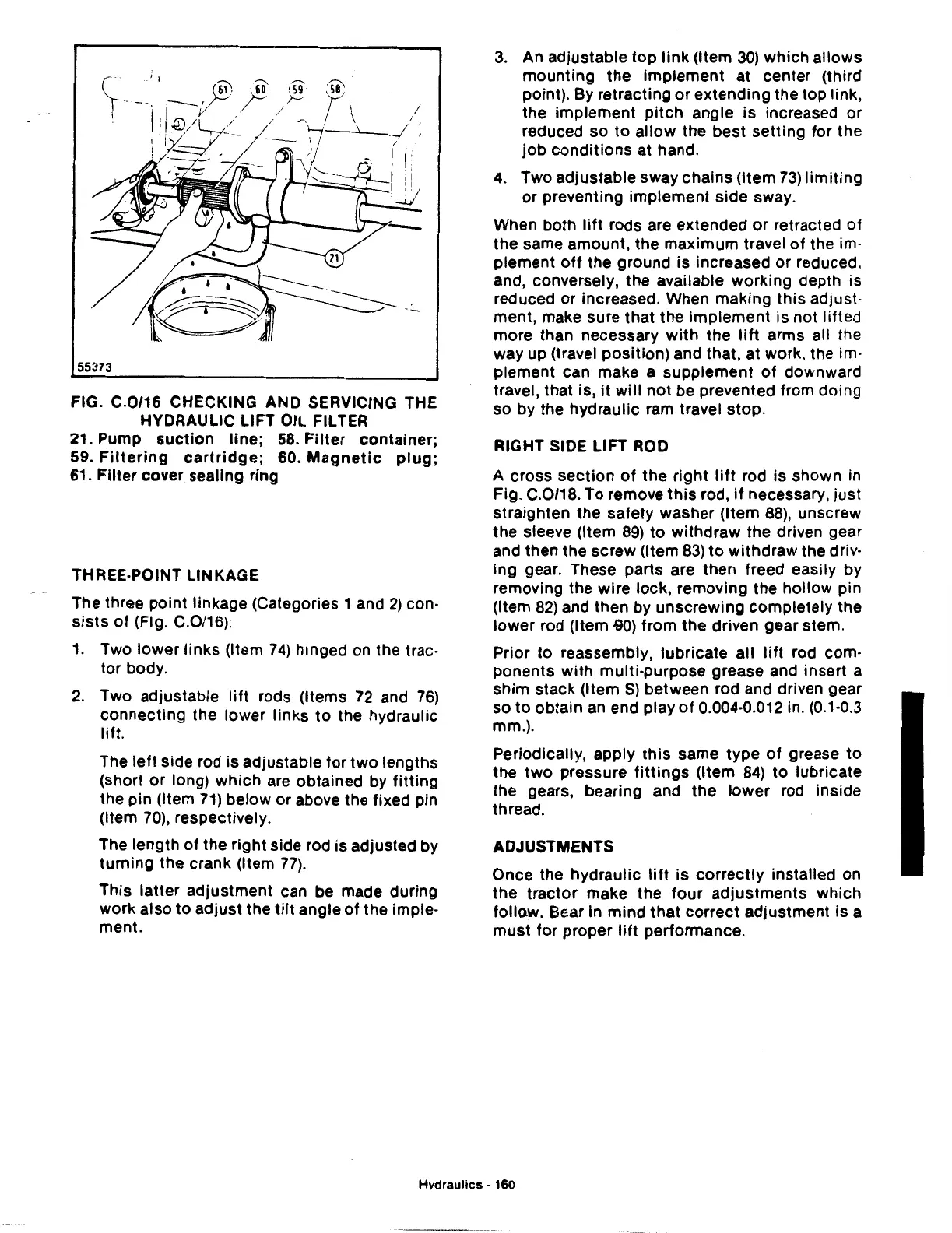

THREE-POINT LINKAGE

The three point linkage (Categories 1 and

2)

con·

sists

of

(Fig. C.0/16):

1.

Two

lower

links

(Item

74)

hinged on the trac·

tor

body.

2.

Two adjustable

lift

rods (Items

72

and

76)

connecting

the lower links

to

the hydraulic

lift.

The

left

side rod is adjustable for

two

lengths

(short

or

long)

which

are obtained by

fitting

the

pin

(Item

71)

below or above the fixed pin

(Item

70),

respectively.

The length

of

the right side rod is adjusted by

turning

the crank (Item

77).

This latter

adjustment

can be made during

work also

to

adjust

the

tilt

angle

of

the imple·

ment.

3.

An adjustable

top

link

(Item

30)

which allows

mounting

the

implement

at center (third

point). By retracting

or

extending

the top link,

the

implement

pitch

angle

is

increased or

reduced

so

to

allow

the

best

setting

for

the

job

conditions

at hand.

4.

Two adjustable sway

chains

(Item

73)

limiting

or preventing

implement

side sway.

When both

lift

rods are extended

or

retracted

of

the

same amount, the

maximum

travel

of

the im·

plement

off

the ground is increased or reduced,

and, conversely,

the

available working depth is

reduced

or

increased. When making

this

adjust·

ment, make sure

that

the

implement

is not lifted

more than necessary

with

the

lift

arms all the

way up (travel

position)

and that, at work, the im·

plement can make a

supplement

of

downward

travel, that is,

it

will

not

be prevented from doing

so by the hydraulic ram travel stop.

RIGHT SIDE

LIFT

ROD

A cross

section

of

the

right

lift

rod is shown in

Fig. C.0/18. To remove

this

rod,

if

necessary,

just

straighten

the

safety washer (Item

88),

unscrew

the

sleeve (Item

89)

to

withdraw

the

driven gear

and then the screw (Item

83)

to

withdraw

the driv·

ing gear. These parts are then freed easily by

removing the wire lock, removing

the

hollow pin

(Item

82)

and then by

unscrewing

completely

the

lower

rod (Item

.go)

from

the

driven gear stem.

Prior to reassembly, lubricate

all

lift

rod com·

ponents

with

multi-purpose grease and insert a

shim

stack

(Item S) between rod and driven gear

so

to

obtain an end play

of

0.004·0.012 in. (0.1·0.3

mm.).

Periodically, apply

this

same type

of

grease

to

the

two

pressure

fittings

(Item

84)

to

lubricate

the

gears, bearing and

the

lower

rod inside

thread.

ADJUSTMENTS

Once the hydraulic

lift

is

correctly

installed on

the

tractor

make

the

four

adjustments

which

follow.

Bear in

mind

that

correct

adjustment

is a

must

for proper

lift

performance.

Hydraulics

· 160

Loading...

Loading...