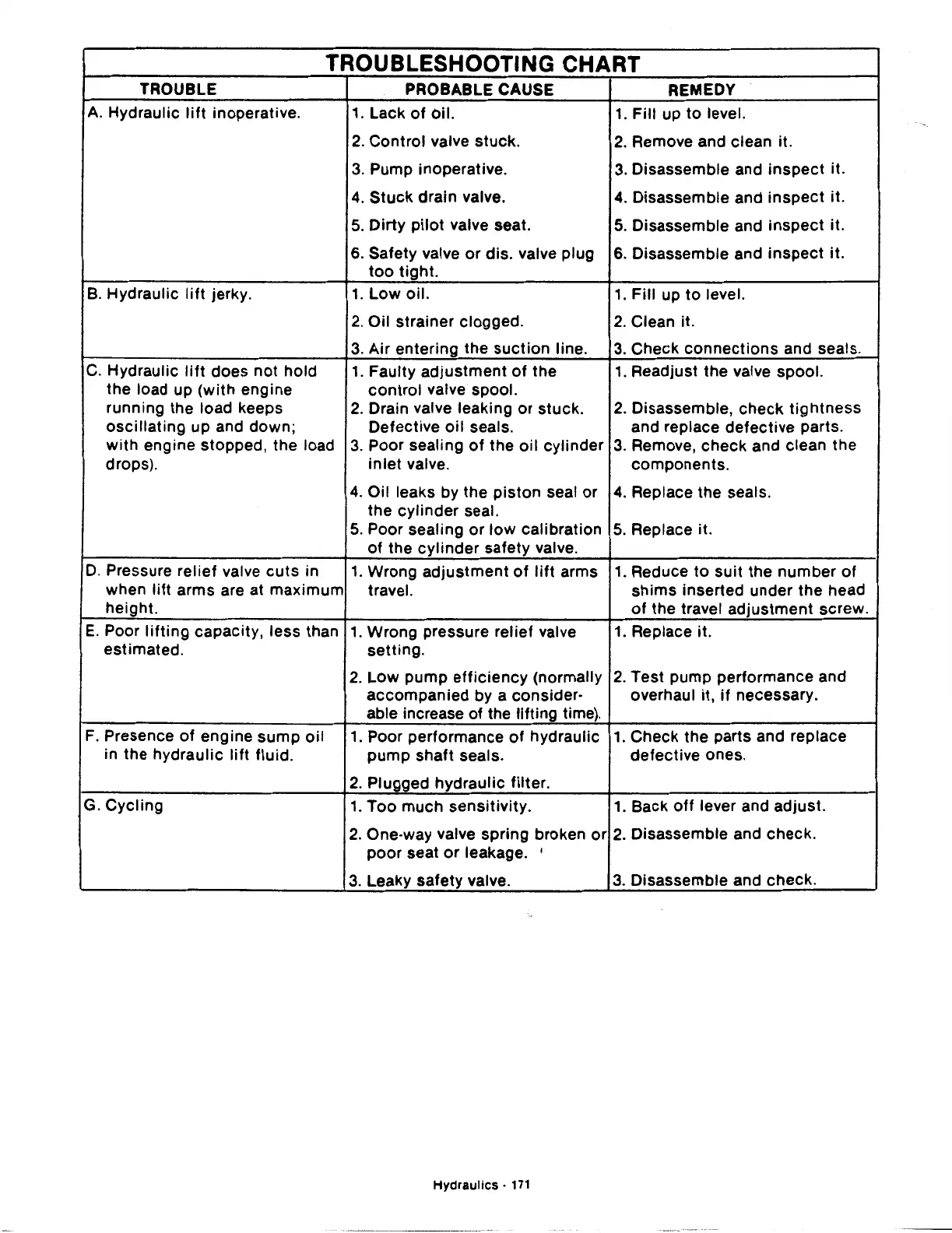

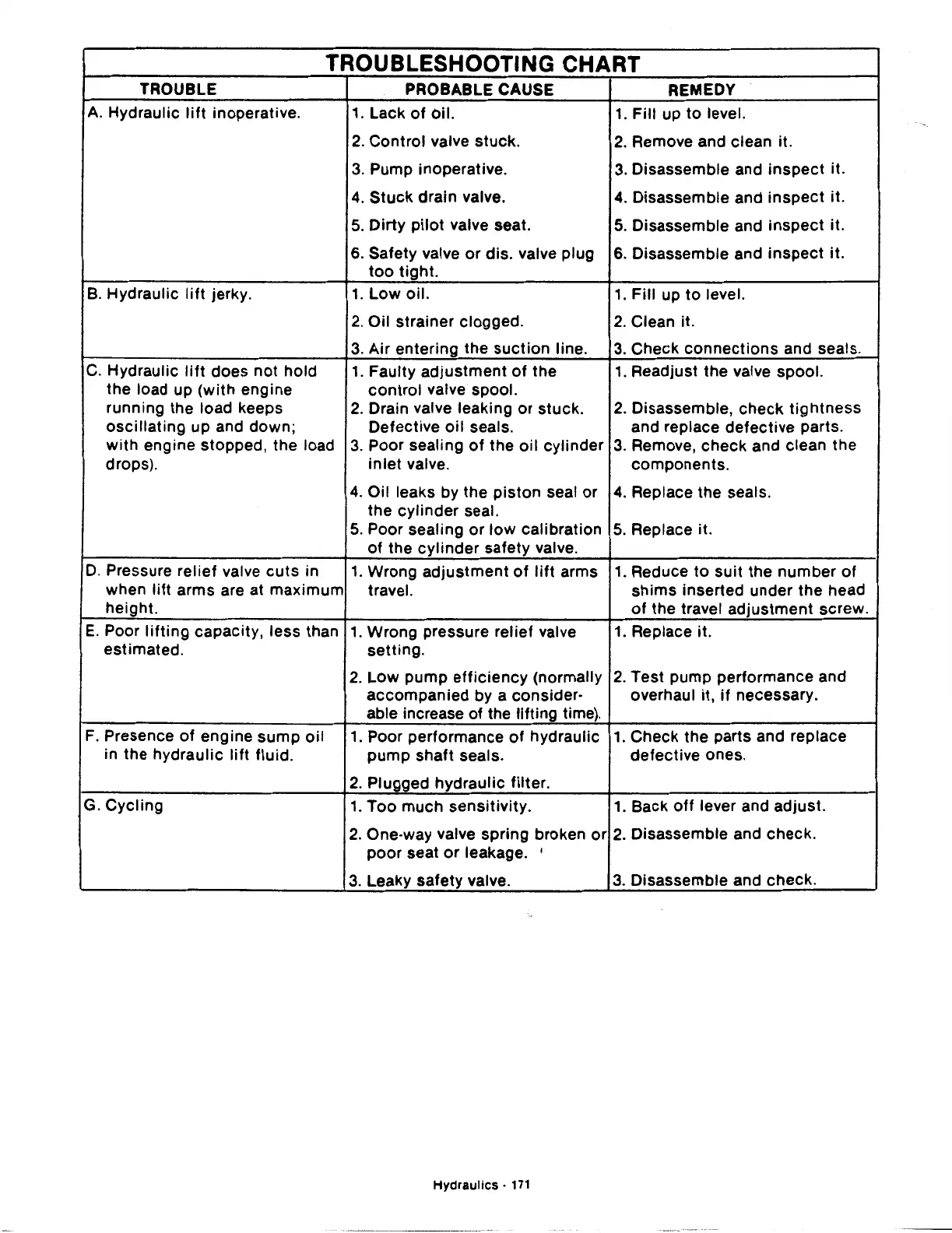

TROUBLESHOOTING CHART

TROUBLE

PROBABLE CAUSE

REMEDY

A.

Hydraulic

lift

inoperative.

1.

Lack

of

Oil.

1.

Fill

up

to

level.

2.

Control valve stuck.

2.

Remove and clean it.

3.

Pump inoperative.

3.

Disassemble and

inspect

it.

4.

Stuck

drain valve.

4.

Disassemble and

inspect

it.

5.

Dirty

pilot

valve seat.

5.

Disassemble and

inspect

it.

6. Safety valve

or

dis. valve plug

6.

Disassemble and

inspect

it.

too

tight.

B.

Hydraulic

lift

jerky.

1.

Low

oil.

1.

Fill

up

to

level.

2.

Oil strainer clogged.

2.

Clean it.

3.

Air

entering the

suction

line.

3.

Check

connections

and seals.

C.

Hydraulic

lift

does

not

hold

1.

Faulty adjustment

of

the

1.

Readjust the valve spool.

the load up (with engine

control

valve spool.

running the load keeps

2.

Drain valve leaking

or

stuck.

2.

Disassemble, check

tightness

oscillating

up and down;

Defective

oil

seals. and replace defective parts.

with

engine stopped, the load

3.

Poor sealing

of

the

oil

cylinder

3.

Remove,

check

and clean the

drops).

inlet

valve. components.

4.

Oil leaks by the

piston

seal or

4.

Replace the seals.

the cylinder seal.

5.

Poor sealing

or

low

calibration

5.

Replace it.

of

the

cylinder

safety valve.

D.

Pressure relief valve

cuts

in

1.

Wrong

adjustment

of

lift

arms

1.

Reduce

to

suit

the

number

of

when

lift

arms are at maximum

travel.

shims

inserted under the head

height.

of

the travel

adjustment

screw.

E.

Poor

lifting

capacity, less than

1.

Wrong pressure relief valve

1.

Replace it.

estimated.

setting.

2.

Low

pump

efficiency

(normally

2.

Test pump performance and

accompanied by a consider·

overhaul it,

if

necessary.

able increase

of

the lifting time).

F.

Presence

of

engine

sump

oil

1.

Poor performance

of

hydraulic

1.

Check the parts and replace

in the hydraulic

lift

fluid.

pump

shaft seals. defective ones.

2.

Plugged hydraulic filter.

G. Cycling

1.

Too much sensitivity.

1.

Back

off

lever and adjust.

2.

One-way valve spring broken

or

2.

Disassemble and check.

poor

seat

or

leakage.

I

3.

Leaky safety valve.

3.

Disassemble and check.

Hydraulics

·

171

Loading...

Loading...