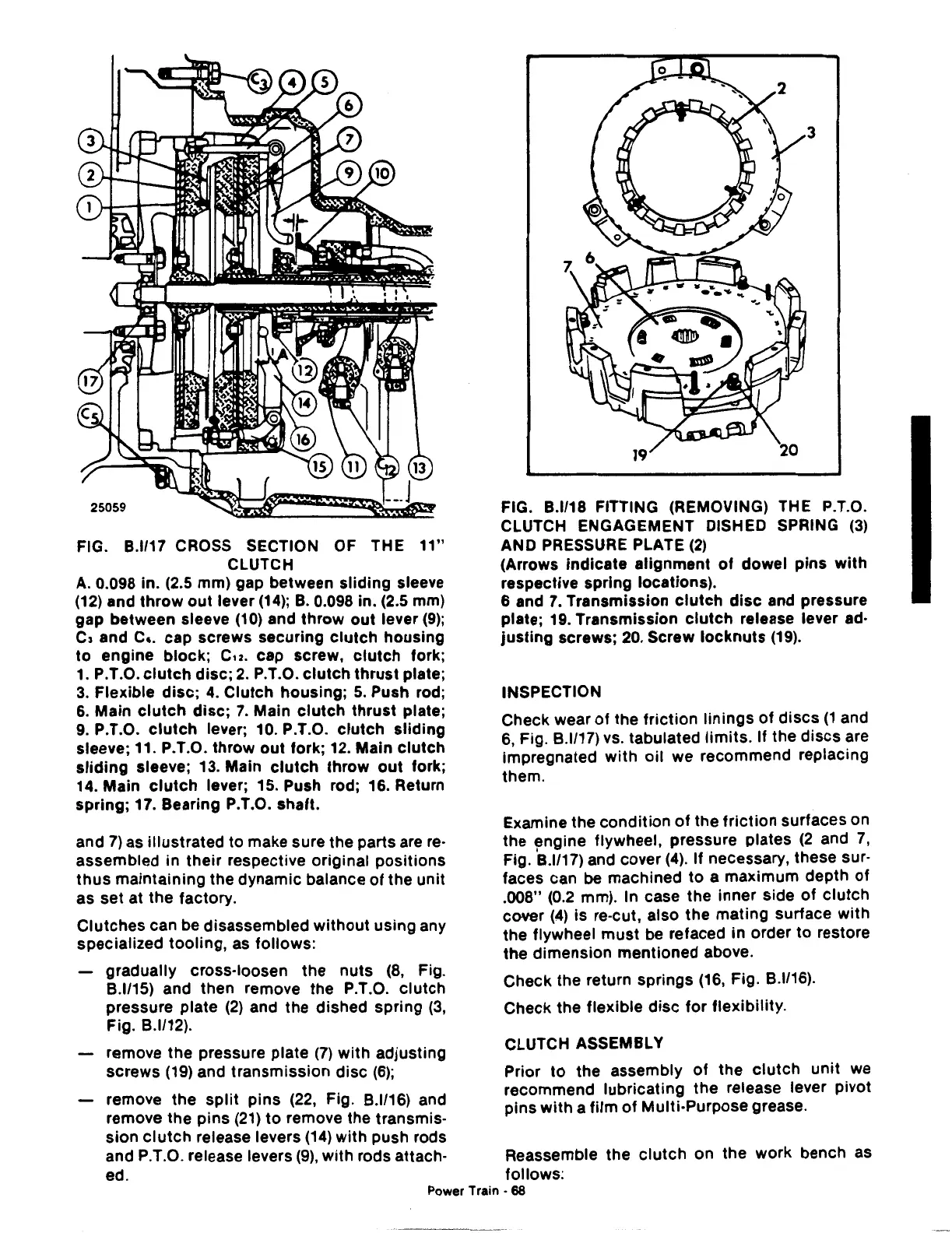

FIG. B.l/17 CROSS SECTION OF THE 11"

CLUTCH

A.

0.098 in.

(2.5

mm) gap between sliding sleeve

(12)

and throw

out

lever

(14);

B.

0.098 in. (2.5 mm)

gap between sleeve

(1

0)

and throw

out

lever (9);

CJ

and c

•.

cap screws securing

clutch

housing

to

engine block; Cu. cap screw,

clutch

fork;

1.

P.T.O.

clutch

disc;

2.

P.T.O.

clutch

thrust

plate;

3.

Flexible

disc;

4.

Clutch housing;

5.

Push rod;

6.

Main

clutch

disc; 7. Main

clutch

thrust

plate;

9. P.T.O.

clutch

lever; 10. P.T.O.

clutch

sliding

sleeve; 11. P.T.O. throw

out

fork; 12. Main

clutch

sliding

sleeve; 13. Main

clutch

throw

out

fork;

14. Main

clutch

lever; 15. Push rod; 16. Return

spring; 17. Bearing P.T.O. shaft.

and

7) as illustrated to make sure the parts are re·

assembled in

their

respective original

positions

thus

maintaining the dynamic balance

of

the unit

as set at

the

factory.

Clutches

can be disassembled

without

using any

specialized

tooling,

as follows:

gradually cross-loosen the nuts

(8,

Fig.

8.1/15)

and then remove the P.T.O. clutch

pressure plate

(2)

and the dished spring

(3,

Fig.

8.1112).

remove

the

pressure plate (7)

with

adjusting

screws

(19)

and transmission disc

(6);

remove the

split

pins

(22,

Fig.

8.1/16)

and

remove the pins

(21)

to

remove the transmis-

sion

clutch

release levers

(14)

with push rods

and P.T.O. release levers

(9),

with

rods attach-

ed.

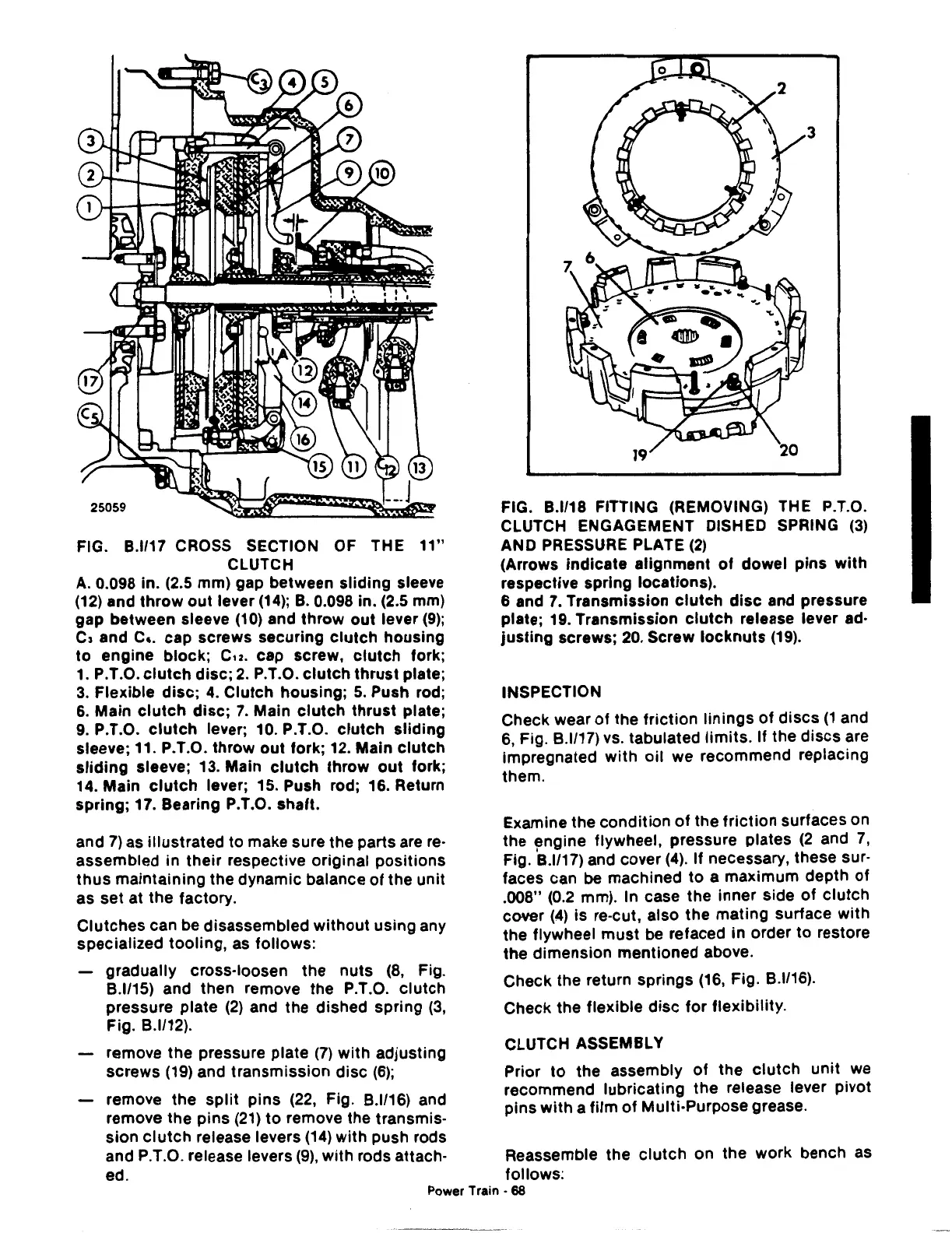

FIG. B.l/18 FITTING (REMOVING) THE P.T.O.

CLUTCH ENGAGEMENT DISHED SPRING

(3)

AND PRESSURE PLATE

(2)

(Arrows indicate alignment

of

dowel

pins

with

respective spring locations).

6 and

7.

Transmission

clutch

disc

and pressure

plate; 19. Transmission

clutch

release lever ad·

justing

screws;

20.

Screw

locknuts

(19).

INSPECTION

Check wear

of

the

friction

linings

of

discs

(1

and

6,

Fig.

8.1117)

vs. tabulated

limits.

If

the

discs

are

impregnated

with

oil we recommend replacing

them.

Examine the condition

of

the

friction

surfaces on

the engine flywheel, pressure plates

(2

and

7,

Fig.

'8.1117)

and cover

(4).

If necessary, these sur-

faces can

be machined

to

a maximum depth

of

.008"

(0.2

mm). In case the inner side

of

clutch

cover

(4)

is re-cut, also

the

mating surface

with

the flywheel

must

be refaced in order to restore

the dimension mentioned above.

Check the return springs

(16,

Fig.

8.1116).

Check the flexible

disc

for

flexibility.

CLUTCH ASSEMBLY

Prior

to

the assembly

of

the

clutch

unit

we

recommend lubricating the release lever pivot

pins

with

a

film

of

Multi-Purpose grease.

Reassemble the

clutch

on the work bench as

follows:

Power Train • 68

Loading...

Loading...