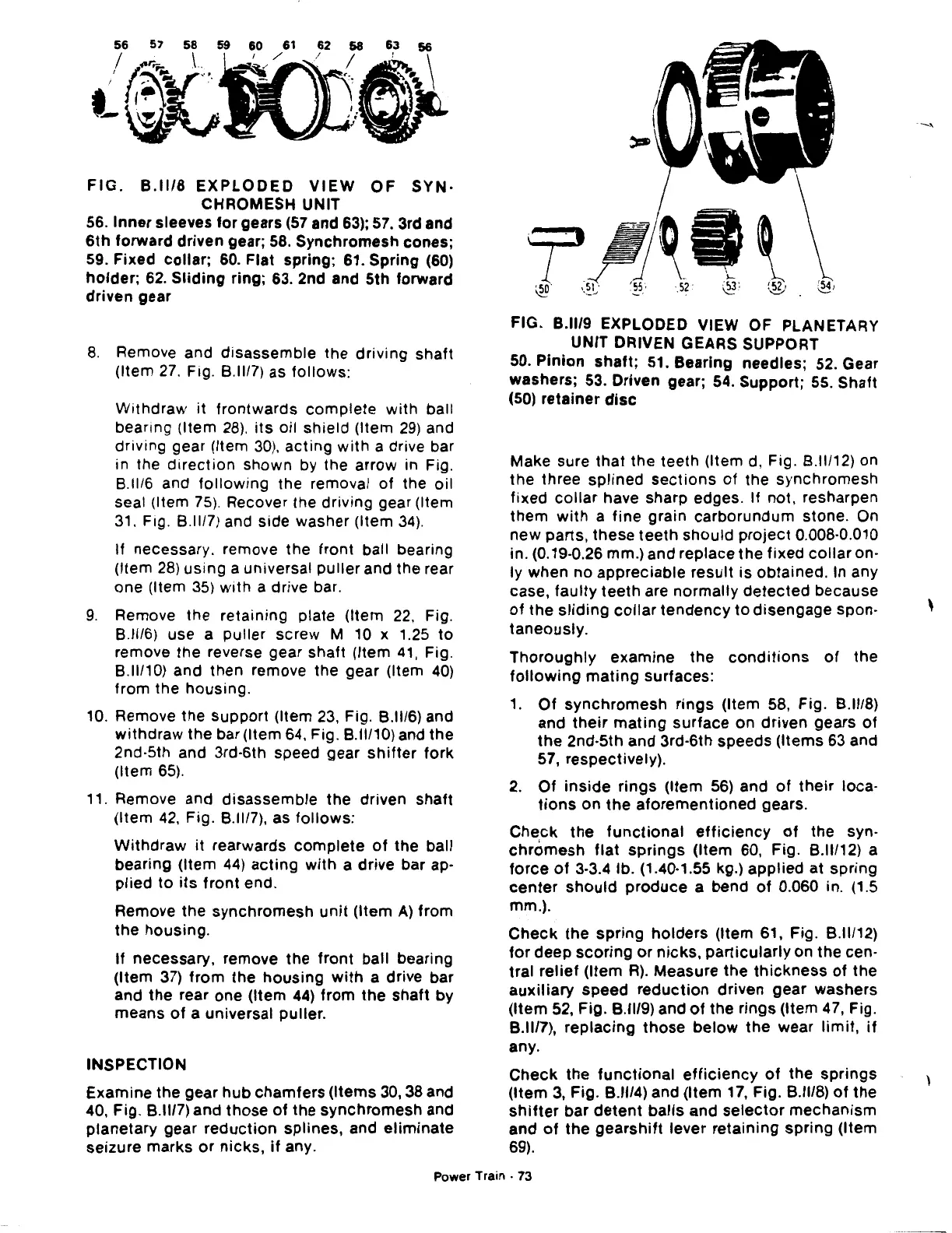

FIG.

B.ll/8

EXPLODED

VIEW

OF

SYN·

CHROMESH UNIT

56.

Inner sleeves for gears

(57

and

63);

57. 3rd and

6th

forward driven gear;

58.

Synchromesh cones;

59. Fixed collar; 60. Flat spring; 61. Spring

(60)

holder;

62.

Sliding

ring; 63. 2nd and 5th forward

driven gear

8.

Remove and disassemble the driving shaft

(Item

27.

Fig.

8.11/7)

as follows:

Withdraw it frontwards

complete

with

ball

bearing (Item

28).

its

oil shield (Item

29)

and

driving gear (Item

30),

acting

with

a drive bar

in the

direction

shown by the arrow in Fig.

8.11/6

and

following

the removal of the oil

seal (Item

75).

Recover the driving gear (Item

31.

Fig.

8.11/7)

and side washer (Item

34).

If necessary. remove the front ball bearing

(Item

28)

using a universal puller and the rear

one (Item

35)

with

a drive bar.

9.

Remove the retaining plate (Item

22,

Fig.

8.11/6)

use a puller screw M

10

x 1.25

to

remove the reverse gear shaft (Item

41,

Fig.

8.11/10)

and then remove the gear (Item

40)

from the housing.

10.

Remove the support (Item

23,

Fig.

8.11/6)

and

withdraw

the bar (Item 64, Fig.

8.11/10)

and the

2nd·5th and 3rd·6th speed gear

shifter

fork

(Item

65).

11.

Remove and disassemble the driven shaft

(Item

42,

Fig.

8.11/7),

as follows:

Withdraw

it rearwards

complete

of

the ball

bearing (Item

44)

acting

with

a drive bar ap-

plied

to

its

front end.

Remove the synchromesh

unit

(Item

A)

from

the housing.

If necessary, remove the front ball bearing

(Item

37)

from the

housing

with

a drive bar

and the rear one (Item

44)

from the shaft by

means

of

a universal puller.

INSPECTION

Examine the gear hub chamfers (Items

30,

38

and

40, Fig.

8.1117)

and those

of

the synchromesh and

planetary gear

reduction

splines, and

eliminate

seizure marks

or

nicks,

if

any.

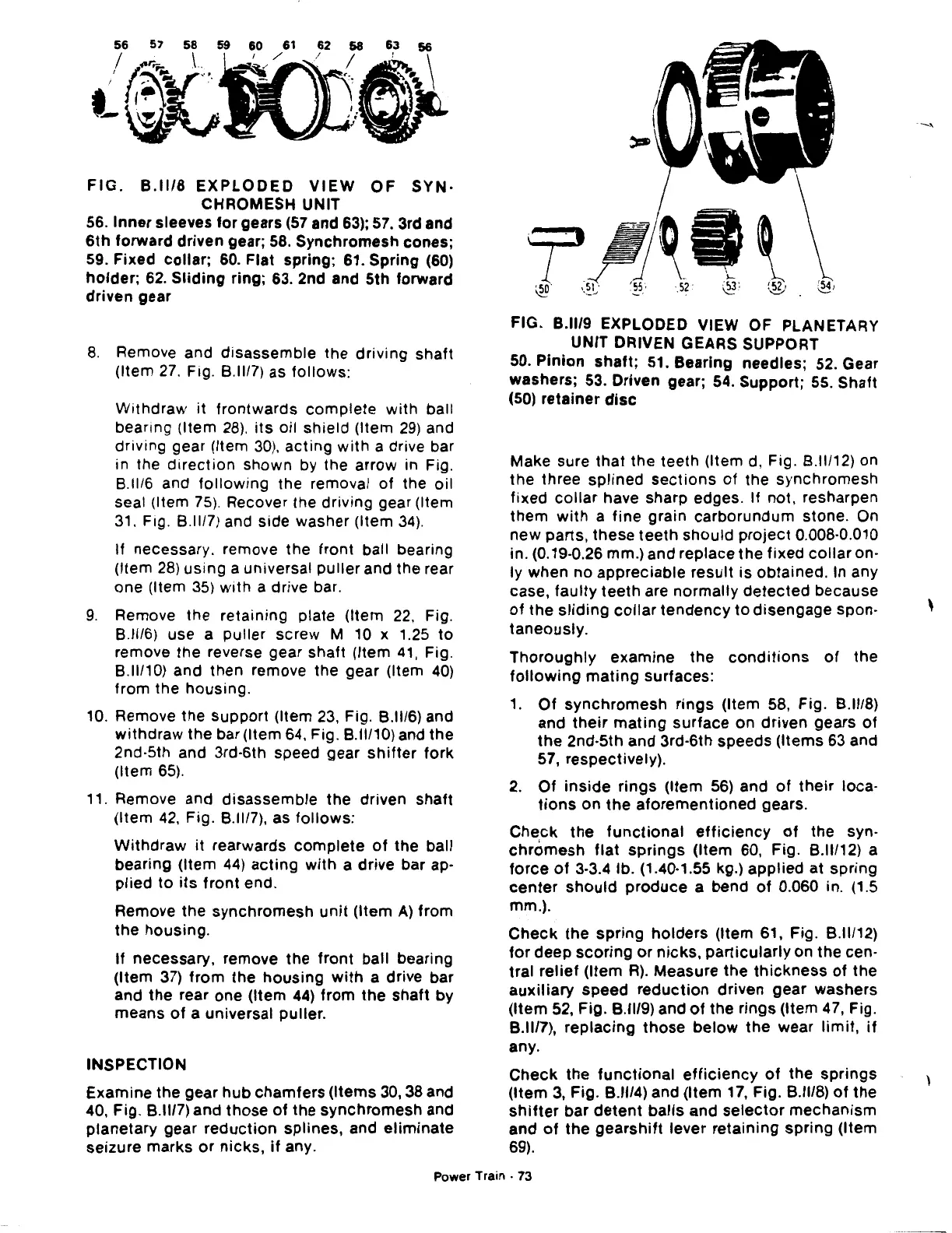

FIG. B.ll/9 EXPLODED VIEW OF PLANETARY

UNIT DRIVEN GEARS SUPPORT

50. Pinion shaft;

51.

Bearing needles;

52.

Gear

washers;

53.

Driven gear;

54.

Support;

55.

Shaft

(50)

retainer

disc

Make sure that the teeth (Item

d,

Fig.

8.11/12)

on

the three splined

sections

of

the synchromesh

fixed

collar

have sharp edges. If not, resharpen

them

with

a fine grain carborundum stone.

On

new parts, these teeth should

project

0.008·0.010

in. (0.19-0.26 mm.) and replace the fixed

collar

on-

ly when no appreciable result is obtained. In any

case, faulty teeth are normally

detected

because

of

the

sliding

collar

tendency

to

disengage spon-

taneously.

Thoroughly

examine the

conditions

of

the

following

mating

surfaces:

1.

Of

synchromesh

rings

(Item 58, Fig.

8.1118)

and

their

mating

surface on driven gears

of

the

2nd-5th and 3rd-6th speeds (Items 63 and

57, respectively).

2.

Of

inside

rings

(Item

56)

and

of

their

loca-

tions

on the

aforementioned

gears.

Check

the

functional

efficiency

of

the syn-

chromesh

flat

springs

(Item 60, Fig.

8.11112)

a

force

of

3·3.4 lb. (1.40·1.55 kg.) applied at spring

center

should

produce a bend

of

0.060 in. (1.5

mm.).

Check

the

spring

holders

(Item 61, Fig.

8.11/12)

for

deep

scoring

or

nicks, particularly on the cen-

tral

relief

(Item

R).

Measure the

thickness

of

the

auxiliary

speed

reduction

driven gear washers

(Item 52, Fig.

8.1119)

and

of

the rings (Item 47, Fig.

8.1117),

replacing

those

below

the wear

limit,

if

any.

Check

the

functional

efficiency

of

the springs

(Item

3,

Fig.

8.1114)

and (Item 17, Fig.

8.11/8)

of

the

shifter

bar

detent

balls

and

selector

mechanism

and

of

the

gearshift

lever retaining spring (Item

69).

Power

Train·

73

'

Loading...

Loading...