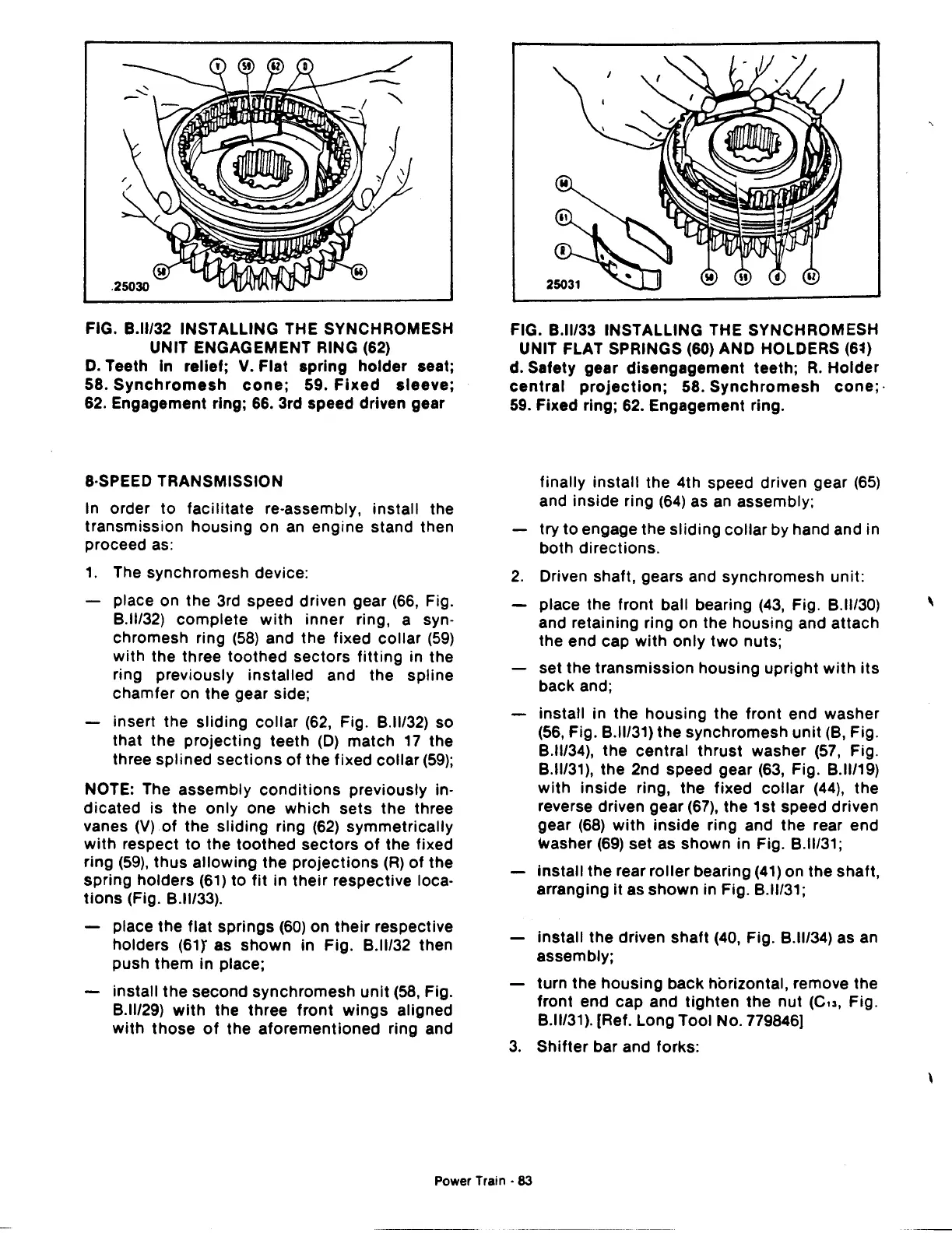

FIG.

8.11/32

INSTALLING THE SYNCHROMESH

UNIT ENGAGEMENT RING (62)

D.

Teeth In relief;

V.

Flat

spring

holder

seat;

58.

Synchromesh

cone;

59.

Fixed

sleeve;

62. Engagement ring; 66. 3rd speed driven gear

8·SPEED TRANSMISSION

In order

to

facilitate re-assembly, install the

transmission housing

on

an

engine stand then

proceed as:

1.

The synchromesh device:

place on

the

3rd speed driven gear

(66,

Fig.

8.ll/32)

complete

with

inner ring, a syn-

chromesh ring

(58)

and the fixed

collar

(59)

with

the three

toothed

sectors

fitting

in the

ring previously installed and the

spline

chamfer on the gear side;

insert the

sliding

collar

(62,

Fig.

8.11/32)

so

that the

projecting

teeth

(D)

match

17

the

three splined

sections

of

the fixed

collar

(59);

NOTE: The assembly

conditions

previously in-

dicated

is

the

only one

which

sets

the

three

vanes

(V)

of

the

sliding

ring

(62)

symmetrically

with

respect

to

the

toothed

sectors

of

the fixed

ring

(59),

thus

allowing

the

projections

(R)

of

the

spring

holders

(61)

to

fit

in

their

respective loca-

tions

(Fig.

8.11133).

place

the

flat

springs

(60)

on

their

respective

holders

(61Y

as

shown

in Fig.

8.11132

then

push

them

in place;

install

the

second synchromesh

unit

(58,

Fig.

8.11129)

with

the three

front

wings

aligned

with

those

of

the

aforementioned

ring and

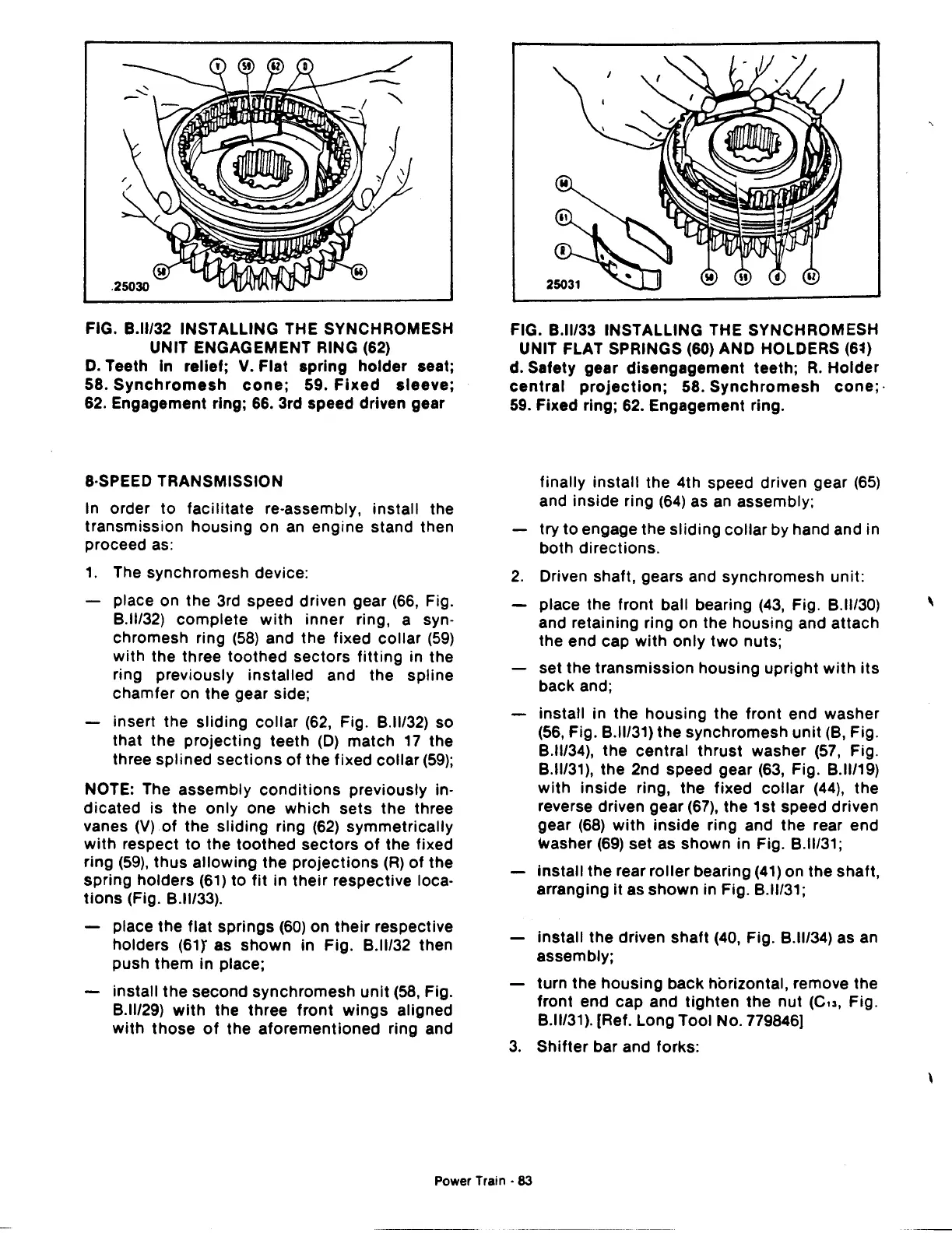

FIG.

8.11133

INSTALLING THE SYNCHROMESH

UNIT FLAT SPRINGS (60) AND HOLDERS

(6~)

d. Safety gear disengagement teeth;

R.

Holder

central

projection;

58.

Synchromesh

cone;·

59.

Fixed ring; 62. Engagement ring.

finally install the 4th speed driven gear

(65)

and

inside

ring

(64)

as

an

assembly;

try

to

engage the

sliding

collar

by hand and in

both directions.

2.

Driven shaft, gears and synchromesh unit:

place the front ball bearing

(43,

Fig.

8.11130)

and retaining ring on the housing and attach

the end cap

with

only

two

nuts;

set

the

transmission

housing

upright

with

its

back and;

install in

the

housing

the front end washer

(56,

Fig.

8.11131)

the

synchromesh

unit

(8, Fig.

8.11134),

the

central

thrust

washer

(57,

Fig.

8.11131),

the 2nd speed gear

(63,

Fig.

8.11119)

with

inside

ring,

the

fixed

collar

(44),

the

reverse driven gear

(67),

the 1st speed driven

gear

(68)

with

inside

ring and

the

rear end

washer

(69)

set as shown in Fig.

8.11131;

install

the

rear

roller

bearing

(41)

on

the

shaft,

arranging

it

as

shown

in Fig.

8.11131;

install

the

driven shaft

(40,

Fig.

8.11/34)

as an

assembly;

turn the

housing

back horizontal, remove the

front end cap and

tighten

the

nut

(Cu,

Fig.

8.11131).

[Ref. Long Tool No. 779846)

3.

Shifter bar and forks:

Power

Train·

83

'

Loading...

Loading...