AXLE REMOVAL

If the

following

procedures have

not

been per-

formed, they

must

be

done

before the axle can

be removed.

1.

Drain

lubricant

from planetary drives and

dif·

ferential.

Position

stand on

either

side

of

the

differential

to

relieve axle

weight

and prevent

axle from

oscillating.

Remove tire and rim

assemblies.

2.

Pull tie rod end at

spindle

support. Remove

spindle retaining cap

screws

at the

spindle

support, and pull planetary

assembly

com-

plete.

To

remove the axle, loosen

lock

nut

and remove

axle

set screw located on the rear

of

the axle

housing.

Place a

block

beneath

inner

yoke

of

the universal

joint.

and pry the axle outward

until

the

0-ring

seal is free of the

housing.

Remove the axle

shaft.

AXLE DISASSEMBLY

To

disassemble

the axle, remove the

0-ring

seal,

external snap ring and internal bearing retaining

snap ring. Pull roller bearing

from

bearing

re-

tainer

and remove inner retaining snap ring.

Press seal from hOusing

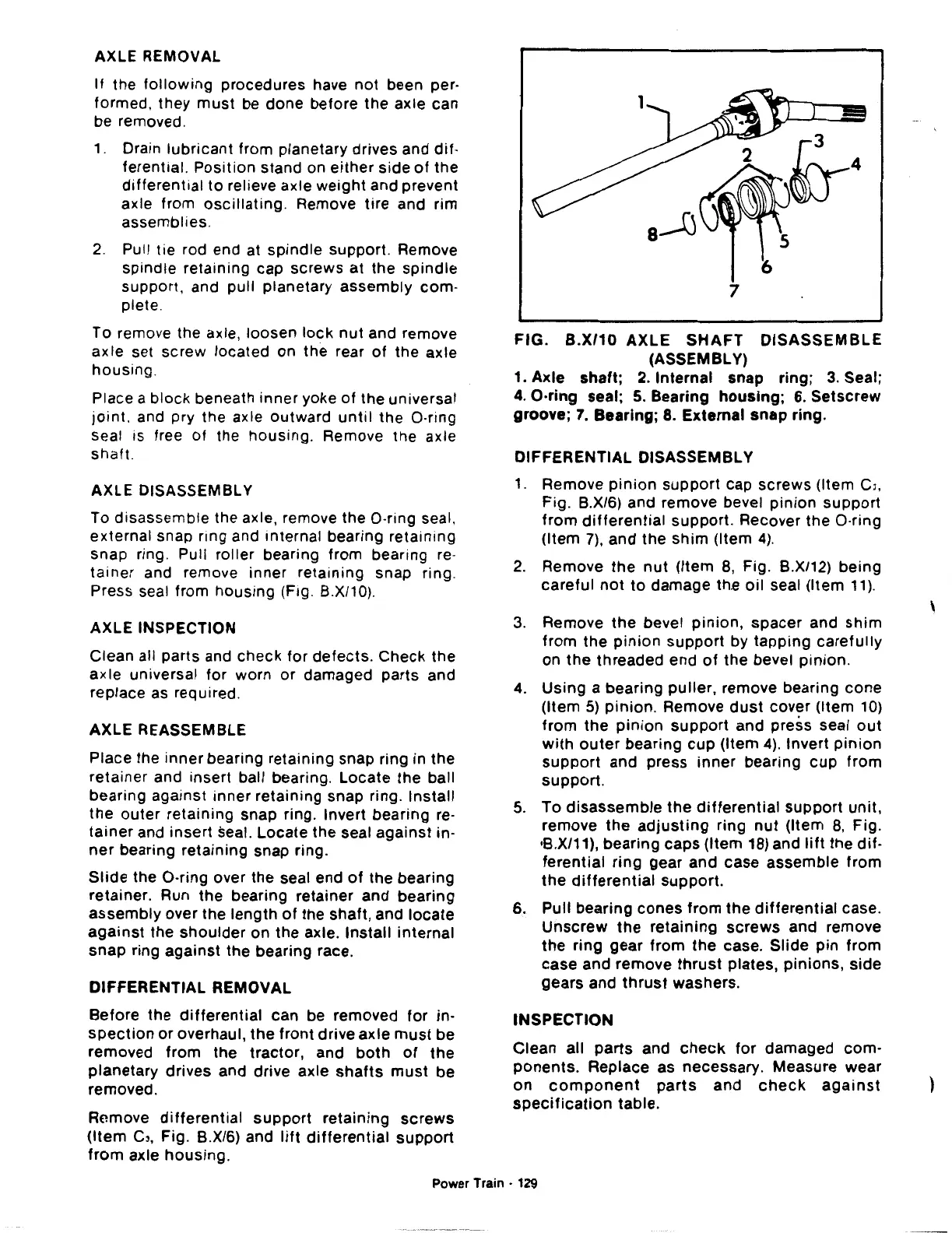

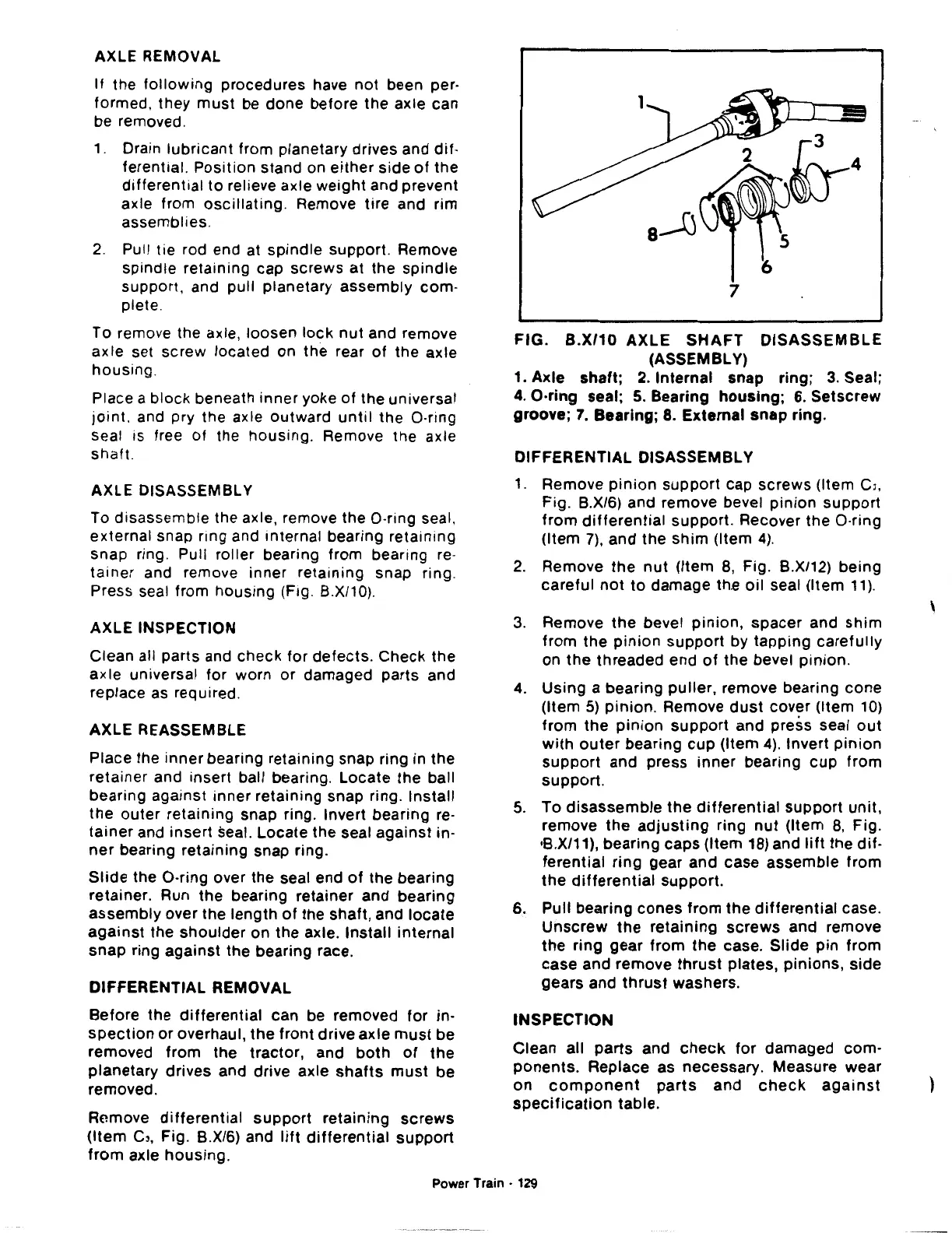

(F1g.

B.X/10).

AXLE INSPECTION

Clean all parts and

check

for

defects.

Check the

axle

universal for worn or damaged parts and

replace as required.

AXLE REASSEMBLE

Place the

inner

bearing retaining snap ring in the

retainer and insert ball bearing. Locate the ball

bearing

against

inner retaining snap ring.

Install

the

outer retaining snap ring. Invert bearing re-

tainer

and

insert

seal.

Locate

the seal

against

in-

ner

bearing retaining snap ring.

Slide

the

0-ring

over the seal end

of

the bearing

retainer. Run

the

bearing retainer and bearing

assembly

over the

length

of

the shaft, and

locate

against

the

shoulder

on

the

axle.

Install

internal

snap

ring

against

the bearing race.

DIFFERENTIAL REMOVAL

Before

the

differential

can be removed

for

in-

spection

or

overhaul,

the

front drive

axle

must

be

removed

from

the tractor, and

both

of

the

planetary

drives

and drive axle

shafts

must

be

removed.

Remove

differential

support

retaining

screws

(Item

Cl, Fig. B.X/6) and

lift

differential

support

from

axle

housing.

8~

6

7

FIG.

B.X/10

AXLE

SHAFT

DISASSEMBLE

(ASSEMBLY)

1.

Axle

shaft;

2.

Internal

snap ring;

3.

Seal;

4.

O·ring seal;

5.

Bearing

housing;

6.

Setscrew

groove;

7.

Bearing;

8. External

snap

ring.

DIFFERENTIAL DISASSEMBLY

1.

Remove

pinion

support

cap

screws

(Item

CJ,

Fig. B.X/6) and remove bevel

pinion

support

from

differential

support. Recover the

0-ring

(Item

7),

and the

shim

(Item

4).

2.

Remove

the

nut

(Item

8,

Fig. B.X/12)

being

careful

not

to

damage

th.e

oil

seal (Item

11).

3.

Remove

the

bevel

pinion,

spacer

and

shim

from

the

pinion

support

by

tapping

carefully

on

the

threaded end

of

the bevel

pinion.

4.

Using

a bearing

puller,

remove bearing

cone

(Item

5)

pinion.

Remove

dust

cover (Item

10)

from

the

pinion

support

and

press

seal

out

with

outer

bearing

cup

(Item

4).

Invert

pinion

support

and

press

inner

bearing

cup

from

support.

5.

To

disassemble

the

differential

support

unit,

remove

the

adjusting

ring

nut

(Item

8,

Fig.

•B.X/11), bearing

caps

(Item

18)

and

lift

the

dif-

ferential

ring

gear

and

case

assemble

from

the

differential

support.

6.

Pull bearing

cones

from

the

differential

case.

Unscrew

the

retaining

screws

and remove

the

ring

gear

from

the

case.

Slide

pin

from

case

and remove

thrust

plates,

pinions,

side

gears

and

thrust

washers.

INSPECTION

Clean all

parts

and

check

for

damaged com-

ponents.

Replace as necessary. Measure wear

on

component

parts

and

check

against

specification

table.

Power Train - 129

'

Loading...

Loading...