into

threaded bore

of

cylinder

rod

(9)

snug

tight

and set clamp

(29).

Bolt

on

cylinder

head

(20),

and

attach

miscellaneous

brackets and

tubing

connections.

A

CAUTION-Lock

nut

(46)

is

still

loose.

After

nut

is

installed

on

tractor

and

alignment

assured

for

free

rocking

movement

of

ball

joints,

do

not

forget

to

tighten

lock

nut

(46)

and set tab

of

safety plate.

Inspect

all

exterior

tubing

connections

and

fastenings:

lock

tabs and

cotter

pins.

Start

tractor

engine

and

allow

cylinder

to

fill

with

oil. Rock steering wheel several times. Cylinder

nearly always purges

itself

of

air, but in event

spongy operation

indicates

airlock, bleed

with

intake line

disconnected;

work steering

cylinder

against

limits

several times. Turn wheel

until

cylinder

is

fully

extended, reconnect inlet hose

finger-tight. Start engine and

allow

oil and air to

trickle

out around

connector

for

2·3 minutes.

Tighten

connector

with

pressure

still

present in

lines.

OPERATION (MICO)

The operation

of

the MICO power steering

cylinder

is

similar

to

the UTB cylinder.

CYLINDER DISASSEMBLY

The MICO power steering

cylinder

can be

disassembled

only

into

two

groups, the

cylinder

and the valve.

Disconnect

hoses from the cylinder. Remove the

cylinder

from the tractor. Recover

grommet

and

washer from shaft end

of

cylinder. Remove

bolts

from

control

valve end. Separate

cylinder

from

control

valve.

To replace

wiper

ring, remove snap ring from

groove

inside

cylinder

barrel. Replace

wiper

ring.

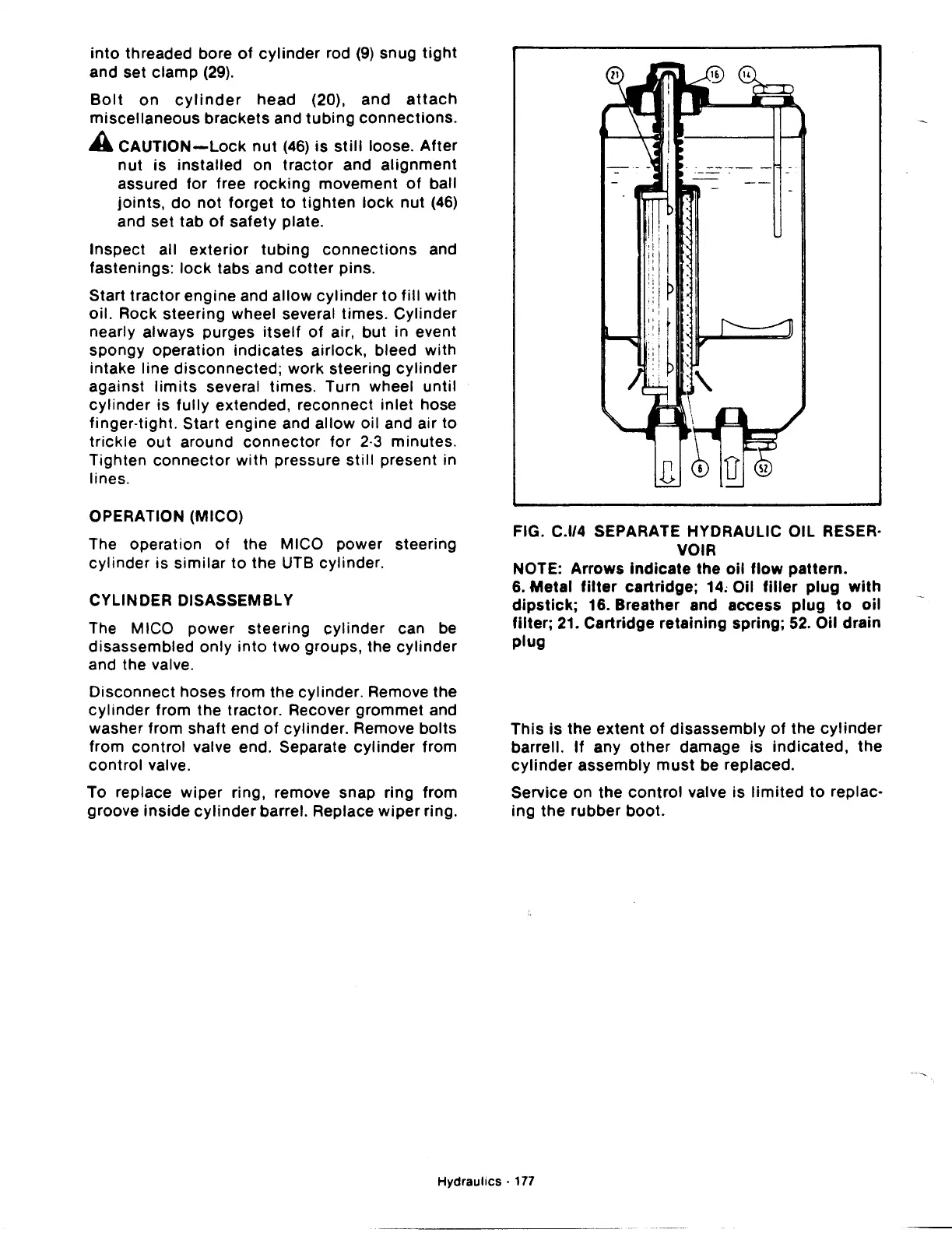

FIG. C.l/4 SEPARATE HYDRAULIC OIL RESER·

VOIR

NOTE: Arrows

indicate

the

oil

flow

pattern.

6.

Metal

filter

cartridge;

14~

Oil

filler

plug

with

dipstick;

16. Breather and access

plug

to

oil

filter;

21. Cartridge

retaining

spring;

52.

Oil drain

plug

This

is

the

extent

of

disassembly

of

the

cylinder

barrel!.

If

any

other

damage

is

indicated,

the

cylinder

assembly

must

be replaced.

Service on the

control

valve

is

limited

to

replac-

ing

the

rubber

boot.

Hydraulics·

177

Loading...

Loading...