2

1--o

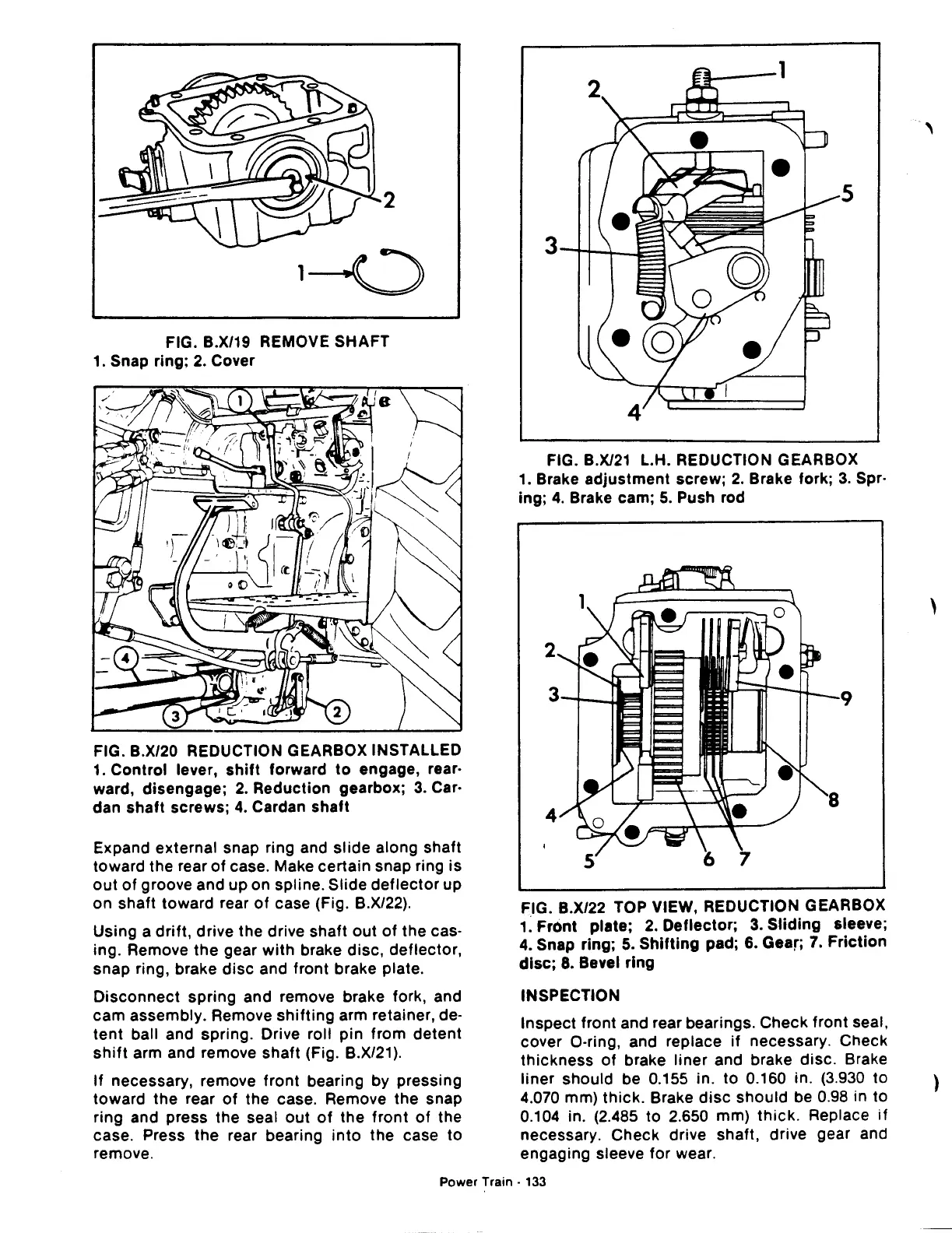

FIG. B.X/19 REMOVE SHAFT

1. Snap ring;

2.

Cover

FIG. B.X/20 REDUCTION GEARBOX INSTALLED

1.

Control lever,

shift

forward

to

engage, rear·

ward, disengage;

2.

Reduction gearbox;

3.

Car·

dan

shaft

screws;

4.

Cardan shaft

Expand external snap ring and slide along shaft

toward the rear

of

case. Make certain snap ring is

out

of

groove and up on spline. Slide

deflector

up

on shaft toward rear

of

case (Fig. B.X/22).

Using a

drift,

drive the drive shaft out

of

the cas·

ing. Remove

the

gear

with

brake disc, deflector,

snap ring, brake

disc

and front brake plate.

Disconnect

spring and remove brake fork, and

cam assembly. Remove

shifting

arm retainer, de-

tent

ball and spring. Drive roll pin from detent

shift

arm and remove shaft (Fig. B.X/21

).

If

necessary, remove

front

bearing by pressing

toward the rear

of

the case. Remove the snap

ring and press the seal

out

of

the

front

of

the

case. Press

the

rear bearing

into

the case to

remove.

5

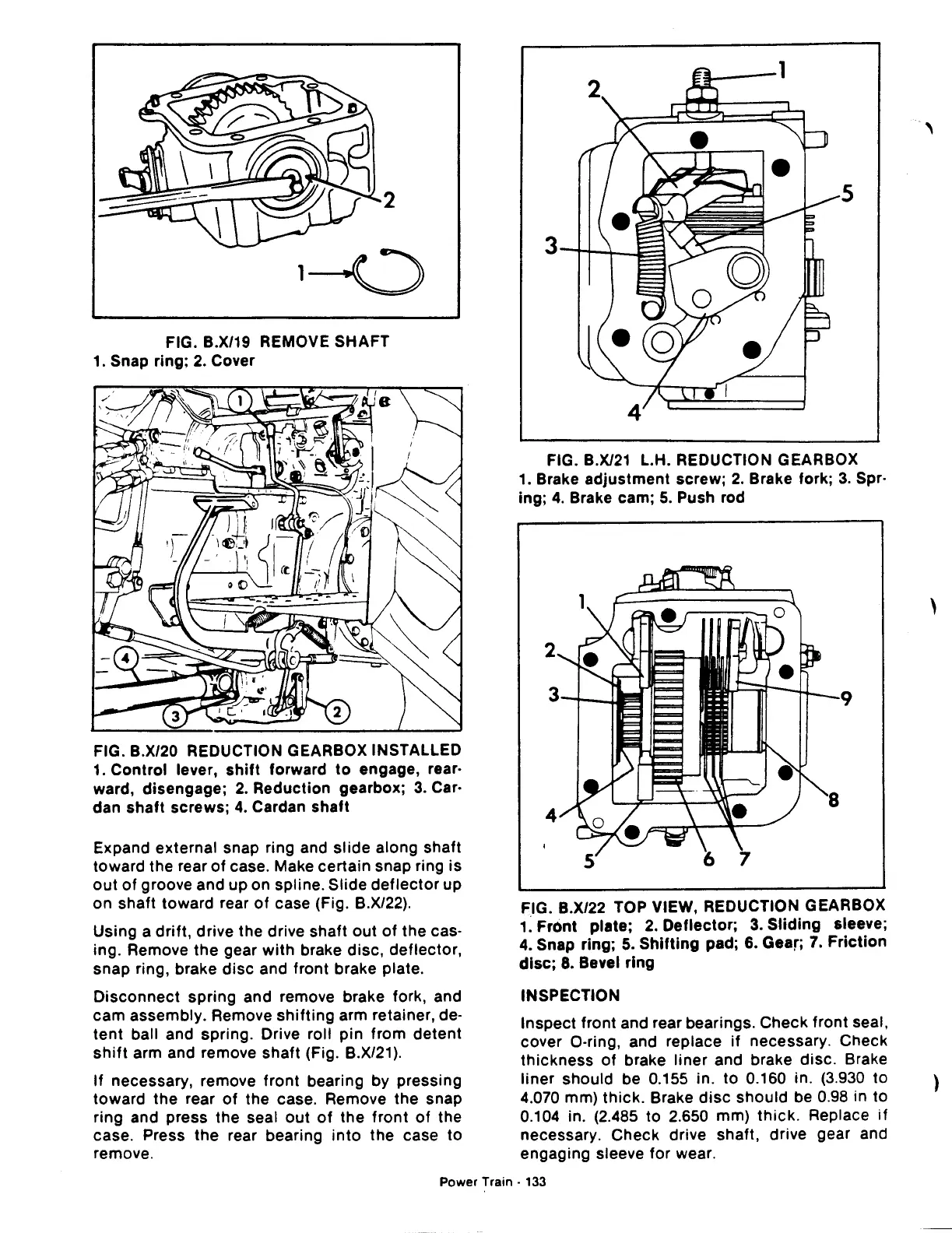

FIG.

B.X/21

L.H. REDUCTION GEARBOX

1.

Brake adjustment screw;

2.

Brake fork;

3.

Spr·

ing;

4.

Brake cam;

5.

Push rod

FIG. B.X/22 TOP VIEW, REDUCTION GEARBOX

1~

Front plate; 2. Deflector; 3.

Sliding

sleeve;

4.

Snap ring;

5.

Shifting

pad; 6. Gear;

7.

Friction

disc;

8. Bevel ring

INSPECTION

Inspect front and rear bearings. Check front seal,

cover 0-ring, and replace

if

necessary. Check

thickness

of

brake liner and brake disc. Brake

liner should be 0.155 in.

to

0.160 in. (3.930 to

4.070 mm)

thick.

Brake

disc

should be 0.98 in to

0.104 in. (2.485 to 2.650 mm)

thick.

Replace

if

necessary. Check drive shaft, drive gear and

engaging sleeve for wear.

Power Train ·

133

'

'

)

Loading...

Loading...