2.

Introduce

into

the right casing a planetary pi·

nion

(36)

only

after

fitting

an

adjusting

screw

(35)

on

its

cylindrical side.

3.

Fit

on the planetary

pinion

the shaft, already

prepared,

fixing

the pin

of

the shaft in the

right

casing hole.

4.

Over the

spider

pinions

put the second

planetary

pinion

provided

with

adjusting

screw.

5.

Over them apply the

left

casing and tighten

the self-locking screws

(Items.,

Fig. B.IX/11)

at a torque value

of

18·25 ft. lbs. (24·34 N·M).

6.

Check,

rotating

by hand the clearance bet·

ween planetary

pinions

and

spider

pinions

flanks

which

must

be

within

.006·.008 in.

(0.15·0.20 mm.) and can be set by means of

the

adjusting

rings.

They

must

rotate freely.

After

performing

this

operation, remove the

left

casing so that the planetary pinion and the thrust

ring

to

remain in the right casing assembly.

7.

Press on the bevel gearing the

left

casing

and

tighten

the self-locking screws at a tor·

que of 51·56 lbs. (69·76 N-m).

8.

Insert from the inside the

two

buttons

M12

and fully

tighten

them

with

the respective

nuts

and secure by bending circlips.

9.

Assemble the

two

casings and

tighten

the 8

screws previously removed, at a torque

of

18·25 ft. lbs. (24·34 N·m).

10.

Simultaneously

press the inner races

of

the

tapered roller bearings (Item

32,

Fig. B.IX/12)

on the

two

casings.

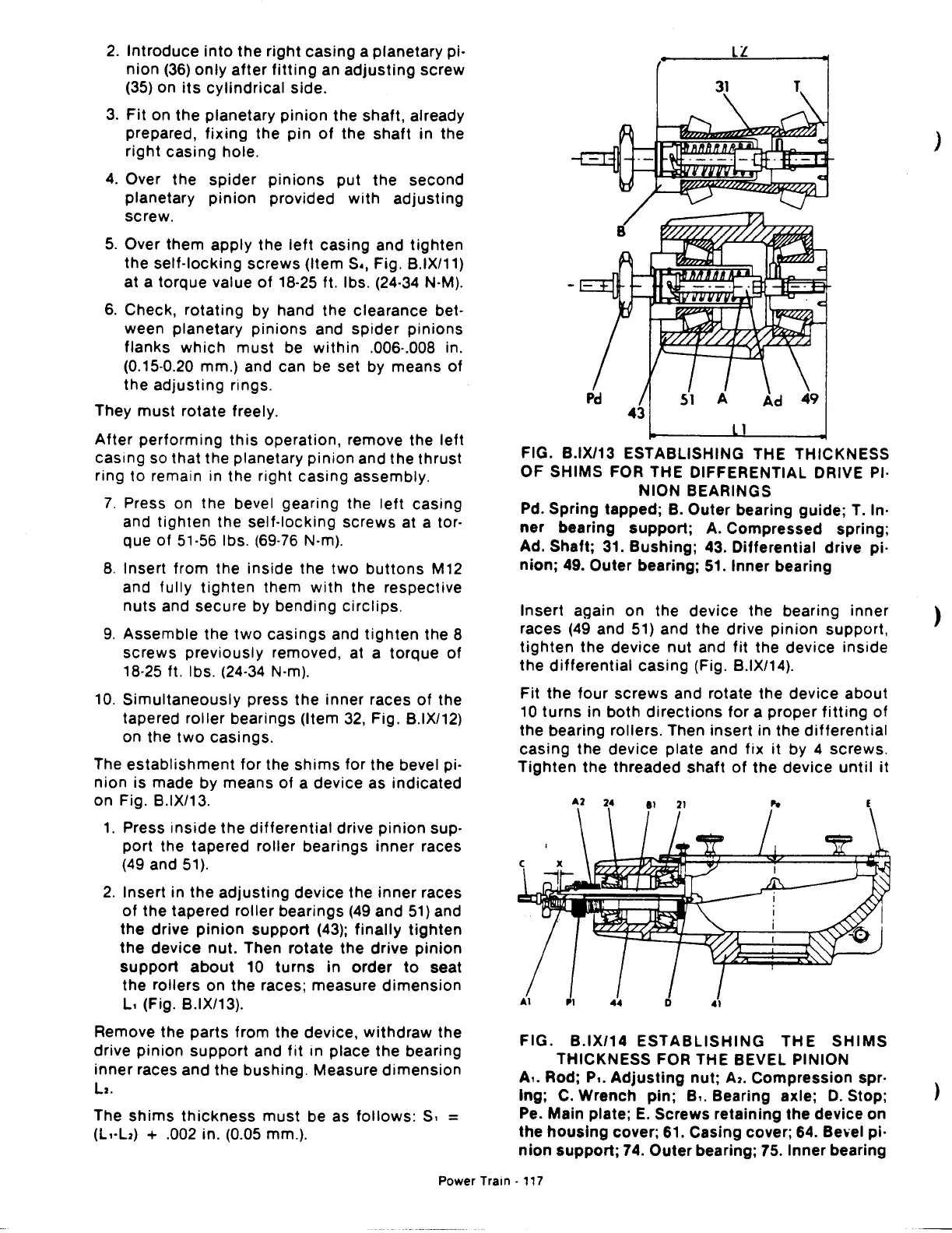

The

establishment

for

the

shims

for the bevel pi·

nion is made by means

of

a device as indicated

on Fig. B.IX/13.

1.

Press

inside

the

differential

drive

pinion

sup·

port the tapered roller bearings

inner

races

(49 and

51).

2.

Insert in the

adjusting

device the inner races

of

the tapered roller bearings

(49

and

51)

and

the

drive

pinion

support

(43);

finally

tighten

the

device

nut.

Then rotate the drive

pinion

support

about

10

turns

in

order

to

seat

the rollers on the races; measure

dimension

L, (Fig. B.IX/13).

Remove the parts from the device,

withdraw

the

drive pinion

support

and

fit

in place the bearing

inner races and the bushing. Measure

dimension

L2.

The

shims

thickness

must

be as

follows:

s,

=

(l··l2)

+ .002 in. (0.05 mm.).

FIG. B.IX/13 ESTABLISHING THE THICKNESS

OF SHIMS FOR THE DIFFERENTIAL DRIVE PI·

NION BEARINGS

Pd. Spring tapped;

B.

Outer bearing guide;

T.

In·

ner

bearing

support;

A. Compressed spring;

Ad. Shaft;

31.

Bushing; 43. Differential drive pi·

nion;

49. Outer bearing;

51.

Inner bearing

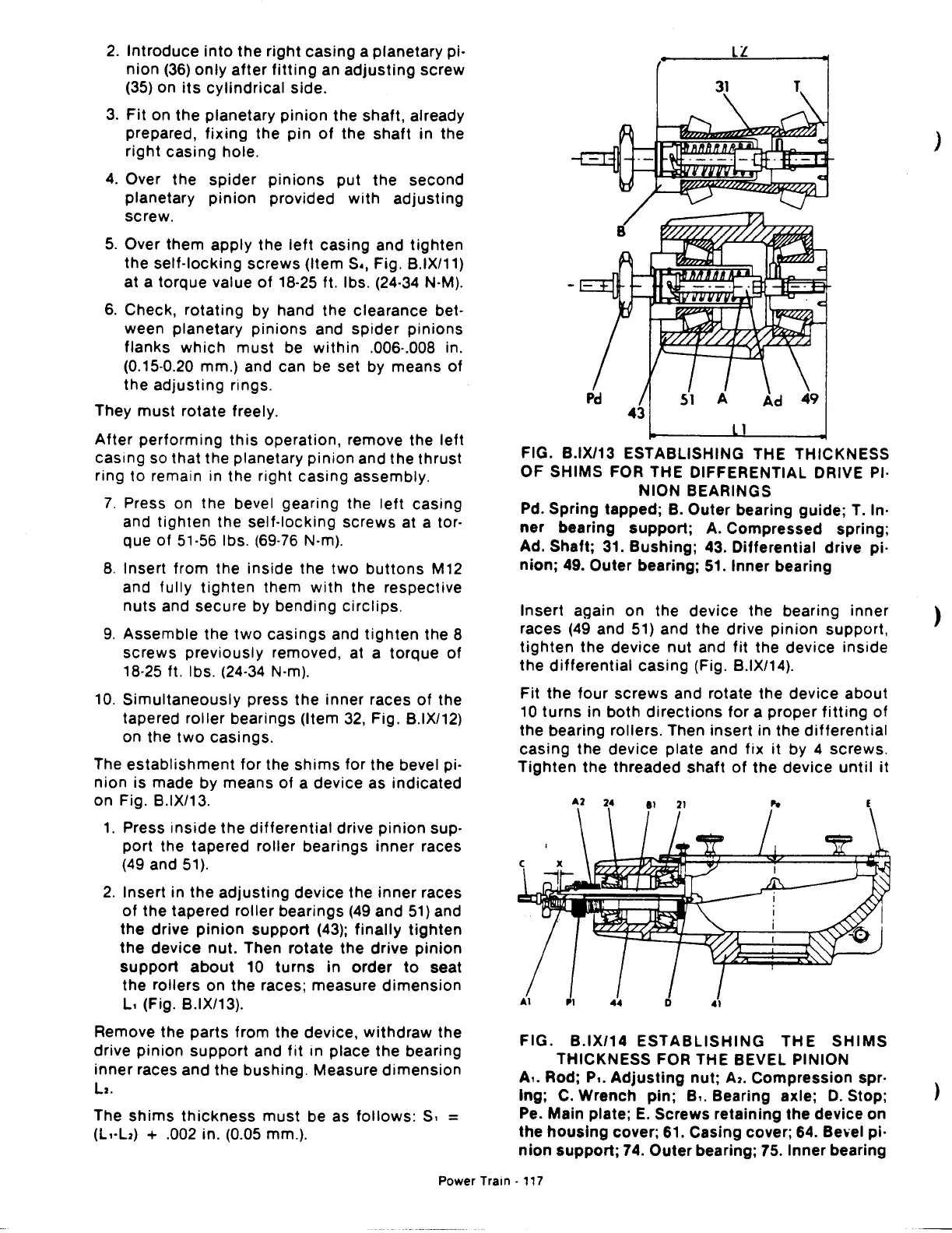

Insert again on the device the bearing inner

races (49 and 51) and the drive

pinion

support,

tighten

the device

nut

and

fit

the device inside

the

differential

casing (Fig. B.IX/14).

Fit

the four

screws

and rotate the device about

10

turns

in

both

directions

for a proper

fitting

of

the bearing rollers. Then insert in the

differential

casing the device plate and fix it by 4 screws.

Tighten

the threaded

shaft

of

the

device

until

it

FIG. B.IX/14

ESTABLISHING

THE

SHIMS

THICKNESS FOR THE BEVEL PINION

A

•.

Rod; P

•.

Adjusting

nut;

A2.

Compression spr·

lng;

C.

Wrench

pin;

B

•.

Bearing axle;

D.

Stop;

Pe. Main plate;

E.

Screws retaining the device on

the

housing

cover;

61.

Casing cover; 64.

Be•wel

pi·

nion

support;

74.

Outer bearing; 75. Inner bearing

Power

Train·

117

)

)

)

Loading...

Loading...