A.IV. FUEL SYSTEM

AIR SUPPLY

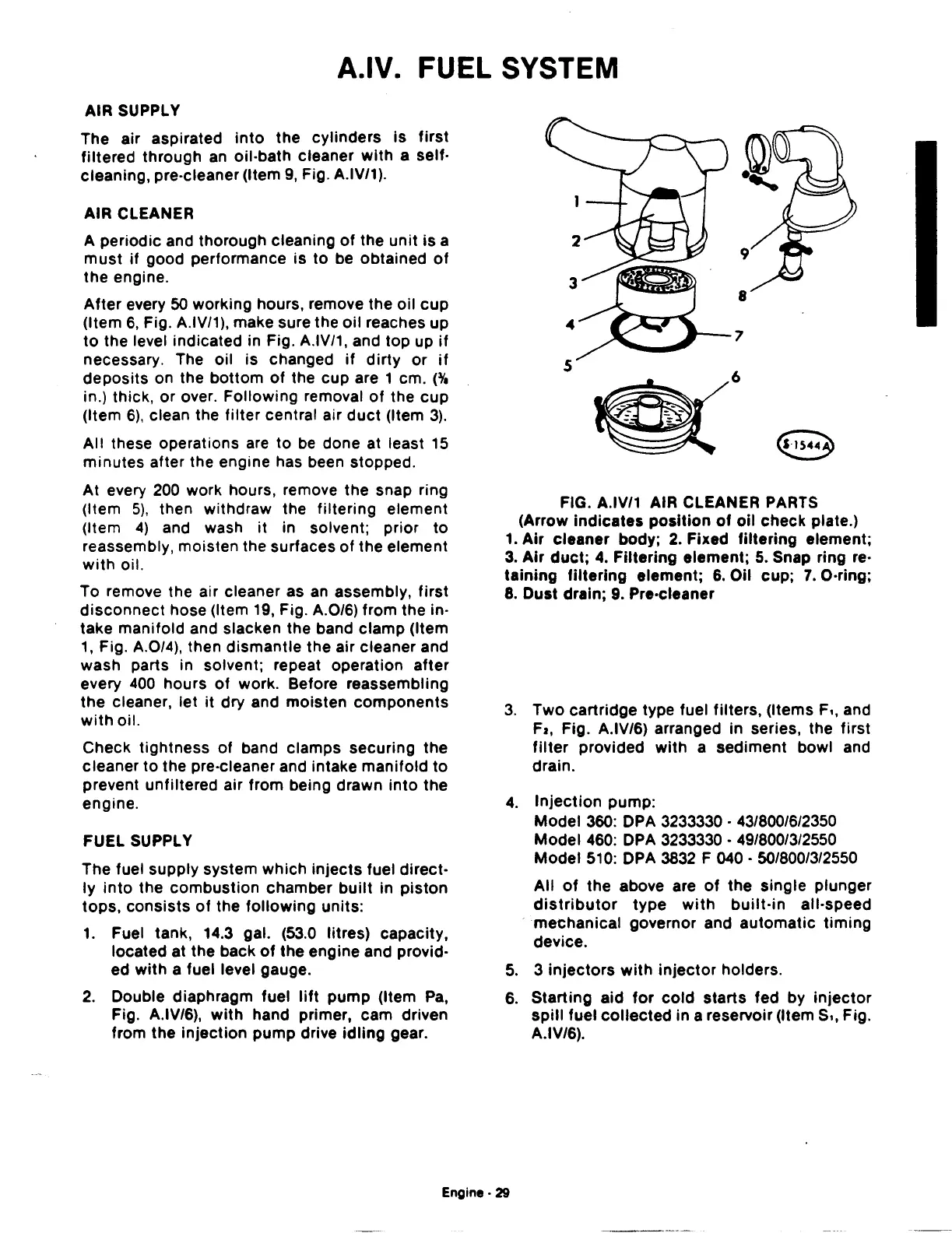

The air aspirated

into

the cylinders is

first

filtered through an oil-bath cleaner

with

a self·

cleaning, pre-cleaner (Item

9,

Fig. A.IV/1).

AIR CLEANER

A periodic and thorough cleaning

of

the

unit

is a

must

if

good performance is

to

be obtained

of

the

engine.

After

every

50

working hours, remove the oil

cup

(Item

6,

Fig. A.IV/1

),

make sure the

oil

reaches up

to

the level indicated in Fig. A.IV/1, and top up

if

necessary. The oil is changed

if

dirty

or

if

deposits

on the bottom

of

the cup are 1 em.

(:Ye

in.) thick, or over. Following removal

of

the cup

(Item

6),

clean the filter central air

duct

(Item

3).

All

these operations are to

be

done at least

15

minutes

after the engine has been stopped.

At every 200 work hours, remove the snap ring

(Item

5),

then withdraw the filtering element

(Item

4)

and wash it in solvent; prior to

reassembly, moisten the surfaces

of

the element

with

oil.

To remove the air cleaner as an assembly, first

disconnect

hose (Item

19,

Fig. A.0/6) from the in·

take manifold and slacken the band clamp (Item

1,

Fig. A.0/4), then

dismantle

the air cleaner and

wash parts in solvent; repeat operation

after

every

400

hours

of

work. Before reassembling

the

cleaner, let

it

dry and moisten

components

with

oil.

Check tightness

of

band clamps securing the

cleaner to the pre-cleaner and intake manifold to

prevent unfiltered air from being drawn

into

the

engine.

FUEL SUPPLY

The fuel supply system which

injects

fuel direct·

ly

into

the

combustion

chamber

built

in

piston

tops,

consists

of

the

following

units:

1.

Fuel tank, 14.3 gal. (53.0 litres) capacity,

located at the back

of

the engine and provid·

ed

with

a fuel level gauge.

2.

Double diaphragm fuel

lift

pump (Item

Pa,

Fig. A.IV/6),

with

hand primer, cam driven

from

the

injection

pump drive

idling

gear.

7

6

FIG. A.IV/1 AIR CLEANER PARTS

(Arrow

indicates

position

of

oil

check plate.)

1.

Air

cleaner body;

2.

Fixed filtering element;

3.

Air

duct;

4.

Filtering element;

5.

Snap ring re·

taining

filtering

element;

6.

Oil cup;

7.

O·ring;

8.

Oust drain; 9. Pre·cleaner

3.

Two

cartridge type fuel filters, (Items F

••

and

Fa,

Fig. A.IV/6) arranged in series, the first

filter

provided

with

a sediment bowl and

drain.

4.

Injection

pump:

Model 360: DPA 3233330 · 43/800/6/2350

Model 460: DPA 3233330 • 49/800/3/2550

Model 510: DPA 3832 F 040 · 50/800/3/2550

All

of

the above are

of

the single plunger

distributor

type

with

built-in

all-speed

mechanical governor and automatic

timing

device.

5.

3

injectors

with

injector

holders.

6.

Starting aid

for

cold

starts

fed by

injector

spill

fuel

collected

in a reservoir

(Items,,

Fig.

A.IV/6).

Engine·

29

Loading...

Loading...